Wire Veneer Drying

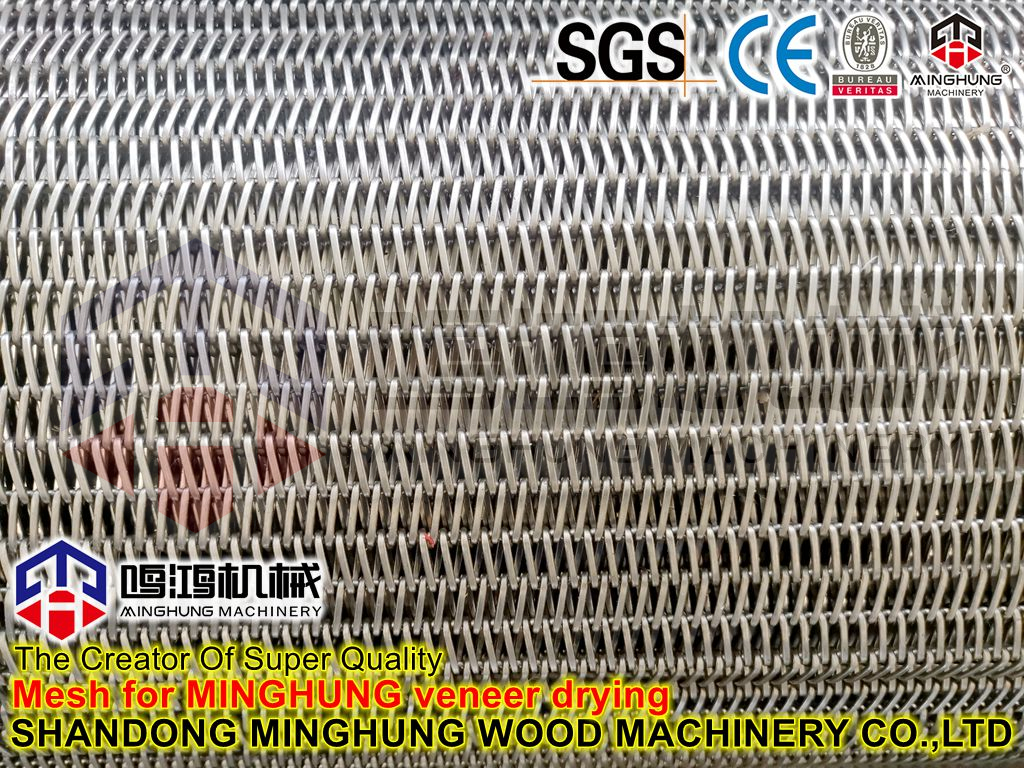

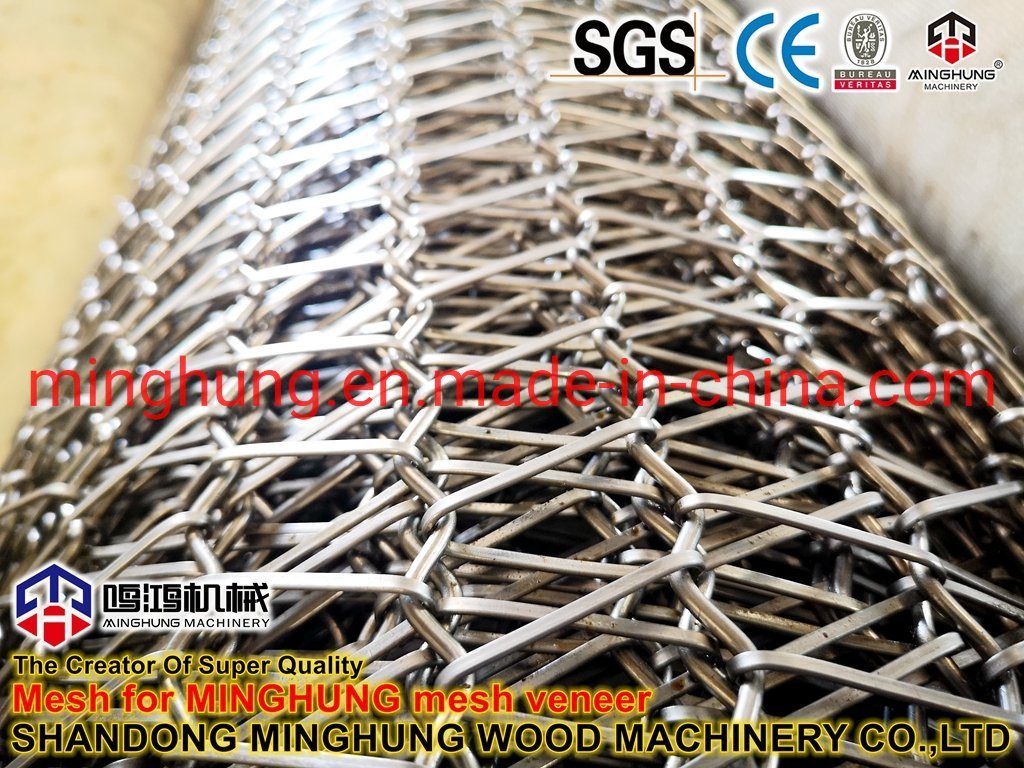

Shandong MINGHUNG Wood Machinery Co.,Ltd is one famous manufacturer of plywood machine in China, Our product Mesh veneer dryer also be called wire dryer, for drying original wood veneer, remove abundant humidity, in the end, the wood veneer humidity will be 5%-10%, so it is suitable for making plywood.

Veneer mesh dryer are suitable for thin wood veneer, and its wire can be stainless steel wire or galvanized wire, and can drying big capacity per day, it can be different length, width and floors. For example, some our clients choose width 4500mm or 4000mm, length 20meters, and four floors, and this wire dryer can drying 40m3 per day.

Our mesh dryer use very thick material for frame and doors, so its weight are heavy a lot; use unique air flue and big fans to increase the production capacity; and use Siemens motor to make sure good quality and powerful energy; even the very small parts like the bearings, we insist choosing the good quality; and each kinds of parts have their own models, so before loading, we will packed each of them and make Marks, so when roller dryer reaches your factory, it is easy for you to know what are they.

Wire dryer includes many different parts, so the production technology and worker rich experience are important, and our factory with this advantage.

Choosing our wire dryer, you can use many years with good performance, and no need worry its quality.

Welcome contact us for more information, we will offer the suitable dryer for you according to your own conditions and requires.

Whatsapp: +8618769900191 +8615589105786 +8615805493072

Email: minghungmachinery@gmail.com

Website: www.plywoodmachineline.com