Ⅰ.Particle Board Introduction

1. Definition & Applications

Particle board is a panel product manufactured from wood fragments (shavings, sawdust, wood chips) through drying, adhesive application (urea-formaldehyde resin or MDI), mat forming, and high-temperature/high-pressure pressing.

Primary Applications: Furniture manufacturing (cabinets, countertops), building interiors (flooring substrates, partitions), packaging materials.

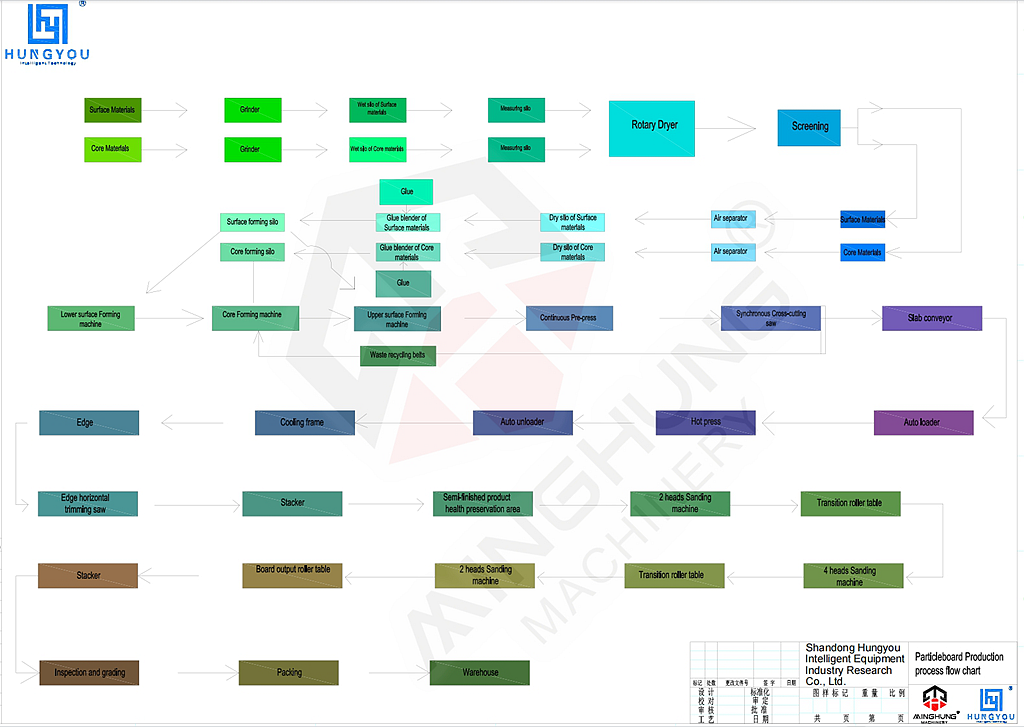

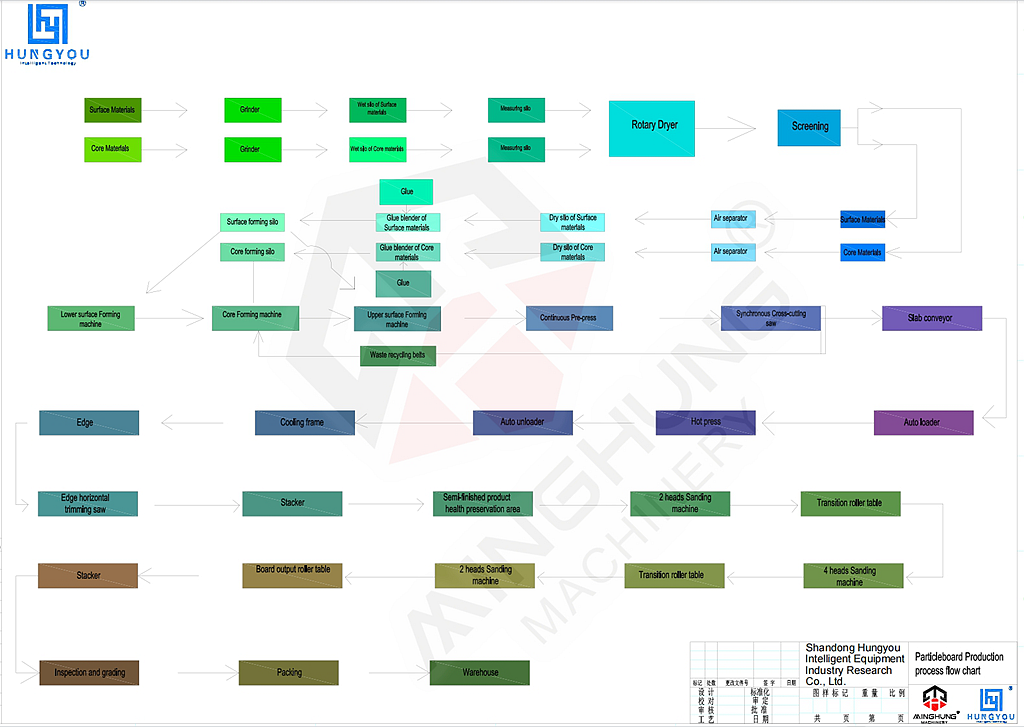

2. Production Process

3. Key Performance Metrics

Density: 550-750 kg/m³ (Medium-Density Particle Board)

Emission Class: E0/E1 (Formaldehyde emission ≤0.5mg/L)

Physical Properties: MOR ≥15MPa, IB ≥0.4MPa (GB/T 4897 Standard)

Ⅱ.Continuous Flat-Pressing Hot Press Details

1. Technical Principle

A continuously moving steel belt transports the formed mat through high temperature (180-220°C) and pressure (2.5-4.5 MPa), enabling adhesive curing and panel consolidation in a single pass.

2. Key Advantages

- 30%+ Higher Efficiency: No open/close cycles, 24/7 operation

- Superior Thickness Uniformity: Tolerance ±0.2mm

- Lower Energy Consumption: 15-20% energy savings via heat recovery

- Flexibility: Produces panels from 1.5mm to 40mm thickness

3. Key Components

System Module | Function | Technical Parameters |

Steel Belt Drive | Continuous mat conveyance | Belt thickness: 1.5-2mm, Width: 2.8m |

Segmented Hydraulic Pressing | 8-12 independent pressure zones | Pressure gradient: Infeed > Center > Outfeed |

Thermal Oil System | Provides stable heat | Temperature control: ±1°C |

Thickness Control | Laser scanning + real-time pressure adjustment | Thickness deviation: ≤0.15mm |

Forming System | Creates uniform mat | Air-sifting/mechanical forming |

double steel belt

double steel belt

Circulating steel strip

hydraulic syetem

hydraulic machine

MINGHUNG PB paving machine

MINGHUNG PB paving machine

mat forming machine

4. Typical Specifications (150,000 m³/year Model)

Press Length: 35-45 meters

Working Width: 2.7m (produces 2,440mm wide panels)

Line Speed: 800-1,500 mm/s (adjustable by thickness)

Installed Power: ~3,500-4,500 kW

Heat Source: Thermal oil boiler (15-20 MW thermal capacity)

Ⅲ. Annual Production Capacity Analysis (150,000 m³)

1.Key Operational Parameters

Parameter | Value | Notes |

Operating Days/Year | 300 days | Includes maintenance downtime |

Daily Production Hours | 22 hours | Accounts for setup/downtime |

Average Thickness | 18mm | Mainstream market thickness |

Board Density | 650 kg/m³ | Medium-density standard |

OEE (Overall Equipment Effectiveness) | 0.85 | Includes speed/availability losses |

2.Production Scale Positioning

Capacity Tier | Annual Output Range | Characteristics |

Small-scale Lines | <80,000 m³ | Batch presses; local markets |

Medium-scale Lines | 80,000–200,000 m³ | 150,000 m³: Core segment |

Large-scale Lines | 200,000–400,000 m³ | Leading players; ample raw material supply required |

Mega-scale Lines | >400,000 m³ | Global giants |

3. Market Competitiveness Analysis

3.1 Efficiency & Economics

Lower breakeven point: ~18% reduced unit cost vs. <100,000 m³ lines

OEE (Overall Equipment Effectiveness): ≥85% (vs. 70–75% for small lines)

Labor efficiency: 30% fewer workers per 10,000 m³ (≈1.5 workers/10,000 m³)

3.2 Technical Adaptability

Continuous press essential: Economically viable only for capacities ≥80,000 m³

Rapid thickness changeover: 1.5–40mm adjustment in 10 mins (vs. 1 hr for multi-opening presses)

3.3 Market Coverage Capability

Metric | 150,000 m³ Line Capacity |

Daily output | ~500 m³ (300 operating days) |

Supply capacity for furniture manufacturers | Supports 10–15 mid-sized factories |

Economical sales radius | 500–800 km (truck transport) |

Our other mechanical products

Pre-sales service:

1) Listen to customer needs

2) Provide preliminary machine design and flow chart for free, select and provide the most reasonable configuration equipment:

3) Support remote meetings and remote factory visits;

4) Provide professional advice to customers and confirm the final selection

5) Support on-site factory visits;

On-purchase service:

1) All equipment must be installed and debugged before leaving the factory, and remote video quality inspection is supported;

2) All machines must be unpacked before leaving the factory, and photos, videos, and annotations must be provided;

3) Free online or offline training for buyers' operators (domestic)

4) Assist buyers in installing and debugging equipment (overseas)

After-sales service:

1) 7*24 hours online service, remote real-time video solution;

2) During the first installation and debugging process, problems encountered during normal operation are solved in time:

3) Regular process inspection and use effect, timely machine maintenance suggestions:

4) Lifetime free technical guidance

5) Timely update the latest industry information.

Shandong MingHung OSB&MDF Machinery Equipment is a China professional factory who specilize in manufacturering and offering Wood based panel machine, including OSB making machine, MDF making machine, and Chipboard /PB making machine.

Our factory with the advanced processing lathes, Mature production technology, and Professional engineers and technicians, and independent ability of reasearch and development, and quickly service, ensure that we have the ability to offer you the suitable and good woodworking machinery as different conditions and requires.

If interested please contact us for a quote.

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com

double steel belt

double steel belt

MINGHUNG PB paving machine

MINGHUNG PB paving machine