The size of a plywood veneer peeling machine is not fixed; it is defined by its design and the log diameter (clamping shaft specification) and log length it can process. It is typically categorized into the following grades:

Therefore, when requesting a quote or selecting a model, the required machine size must be determined based on the log specifications you commonly use.

The working principle of the veneer peeling machine is based on "Centered Rotary Cutting".

1. Clamping and Rotation: The log section is placed between two large clamping shafts. Driven by hydraulic or mechanical power, the shafts move towards the center, pierce into, and tightly clamp both ends of the log.

2. Rotary Motion: The clamping shafts drive the log to rotate at a constant speed.

3. Linear Cutting: Simultaneously, the peeling knife (a long, sharp blade), mounted on a precision tool rest, performs a continuous, precise linear feed motion relative to the rotating log.

4. Veneer Formation: For each rotation of the log, the peeling knife advances a set distance (equal to the veneer thickness). Thus, the blade peels the log layer by layer in a continuous ribbon, forming a long, continuous sheet of veneer with uniform thickness.

1. Loading: The cut and softened (conditioned) log sections are transported to the peeling machine's front table via rollers or a crane.

2. Centering: Mechanical or hydraulic centering devices align the log's rotational center with the axis of the clamping shafts. This is a crucial step for ensuring high veneer yield and quality.

3. Clamping: The clamping shafts extend, pierce the log ends, and clamp it securely.

4. Peeling: The main motor starts. The clamping shafts rotate the log, while the knife carriage rapidly advances to the set position and begins the uniform-speed peeling process. The peeled veneer ribbon is conveyed out via discharge rollers.

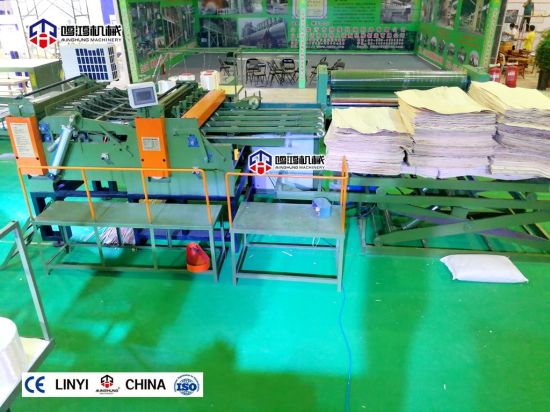

5. Veneer Handling: The continuous veneer ribbon is either wound onto a reeling machine at the rear or cut into sheets of specific lengths by a clipper.

6. Core Ejection: When the log is peeled down to its final diameter (typically a core of 60-80mm), the clamping shafts release, and the core drops onto a conveyor for removal.

7. Reset: The knife carriage and clamping shafts return to their starting positions, ready for the next work cycle.

A complete veneer peeling machine is a complex system, primarily consisting of:

Base & Bed: The foundation of the entire equipment, requiring extremely high rigidity and stability.

Headstock & Tailstock: House the main and auxiliary clamping shafts respectively, providing rotational power and clamping force.

Tool Rest Assembly: Includes the knife carriage, knife bar, pressure bar, etc. The pressure bar compresses the log just ahead of the knife edge to prevent splitting and ensure smooth veneer separation.

Feed System: Typically consists of a servo motor and precision ball screw, controlling the feed speed of the knife carriage to accurately determine veneer thickness.

Hydraulic System: Provides power for clamping shaft operation, centering devices, etc.

Electrical Control System: The PLC (Programmable Logic Controller) is the brain, often integrated with a touchscreen for parameter setting (e.g., veneer thickness, peeling speed), enabling automated control.

Drive System: Includes the main motor, gearbox, gears, etc., for transmitting power.

Modern specialized plywood veneer peeling machines offer significant advantages over older models:

High Precision & Uniformity: Use of servo motors and precision ball screws for feed control ensures minimal veneer thickness tolerance (can reach ±0.05mm), laying the foundation for high-quality plywood production.

High Efficiency: High degree of automation reduces manual intervention, shortens cycle times, and increases output.

High Veneer Yield: Precise centering systems find the optimal rotational center of the log, minimizing "debris" and "wedge-shaped veneer," thereby improving wood utilization.

Automation & Intelligence: PLC control, digital parameter setting, user-friendly operation, fault diagnosis capabilities. Some high-end models can also perform data acquisition and remote monitoring.

Strong Stability: Robust bed structure and high-quality components ensure stable operation under long-term heavy loads with low failure rates.

Strong Adaptability: Can be adjusted via parameters to suit different wood species (e.g., Eucalyptus, Poplar, Birch), different diameters, and different thickness requirements.

Pre-sales service:

1) Listen to customer needs

2) Provide preliminary machine design and flow chart for free, select and provide the most reasonable configuration equipment:

3) Support remote meetings and remote factory visits;

4) Provide professional advice to customers and confirm the final selection

5) Support on-site factory visits;

On-purchase service:

1) All equipment must be installed and debugged before leaving the factory, and remote video quality inspection is supported;

2) All machines must be unpacked before leaving the factory, and photos, videos, and annotations must be provided;

3) Free online or offline training for buyers' operators (domestic)

4) Assist buyers in installing and debugging equipment (overseas)

After-sales service:

1) 7*24 hours online service, remote real-time video solution;

2) During the first installation and debugging process, problems encountered during normal operation are solved in time:

3) Regular process inspection and use effect, timely machine maintenance suggestions:

4) Lifetime free technical guidance

5) Timely update the latest industry information.

We are Shandong MINGHUNG Wood Based Panel Machinery Co.,Ltd China factory and manufacturer of full sets of Plywood machinery and Veneer machinery. With many years production experience, advanced production technology,experienced workers and professional engineers, we can offer you the suitable, good and strong machinery for you.

The machinery we produce includes peeling machines, chipping machines, rotary cutting machines, drying machines, gluing mixers, laying machines, pre-pressing machines, hot pressing machines, cooling machines, longitudinal and transverse sawing machines, sanding machines, as well as auxiliary machinery such as automatic feeding and discharging systems and lifting platforms.