Specifications & Customization

Core Material: Available with all-solid-wood cores including Eucalyptus, Poplar, Birch, Beech, etc.

Thickness: Standard thickness from 3mm to 25mm, customizable based on client requirements.

Size: Standard 4' x 8' (1220mm x 2440mm) is available, other custom sizes are also supported.

Grade: Various face/back veneer grades like AA/BB, AB/BB are offered. Customization including melamine paper overlay or natural wood veneer finishing is available.

Packaging: Export-standard moisture-proof packaging ensures quality during long-distance shipping.

The production of formaldehyde-free plywood imposes extremely high requirements on equipment cleanliness, precision, and stability to ensure the final product meets stringent environmental and safety standards.

| 1. Raw Material Processing Section Equipment |

Debarker and Bucking Saw: Debarks logs and cuts them into specific lengths.

Lathe / Peeler: This is one of the key pieces of equipment. It peels the log sections into continuous, uniform thin veneers. The precision of this machine directly determines the thickness consistency and surface smoothness of the veneers, which is fundamental for subsequent low glue consumption and high-quality bonding.

Veneer Dryer: Typically uses roller or mesh belt dryers. It dries the wet veneers after peeling to a suitable and uniform moisture content. Precise drying is crucial to prevent warping, cracking, and to ensure bond strength.

|  |  |  |

| log debarker | log fixed size cutting | veneer peeling machine | drying machine |

| 2. Glue Application and Layup Section Equipment |

Formaldehyde-Free Glue Preparation System: A highly automated system for storing, mixing, and conveying formaldehyde-free adhesives (e.g., soy protein glue, polyurethane resin - PU glue). The system is usually equipped with precise temperature control and metering devices to ensure glue activity and ratio stability.

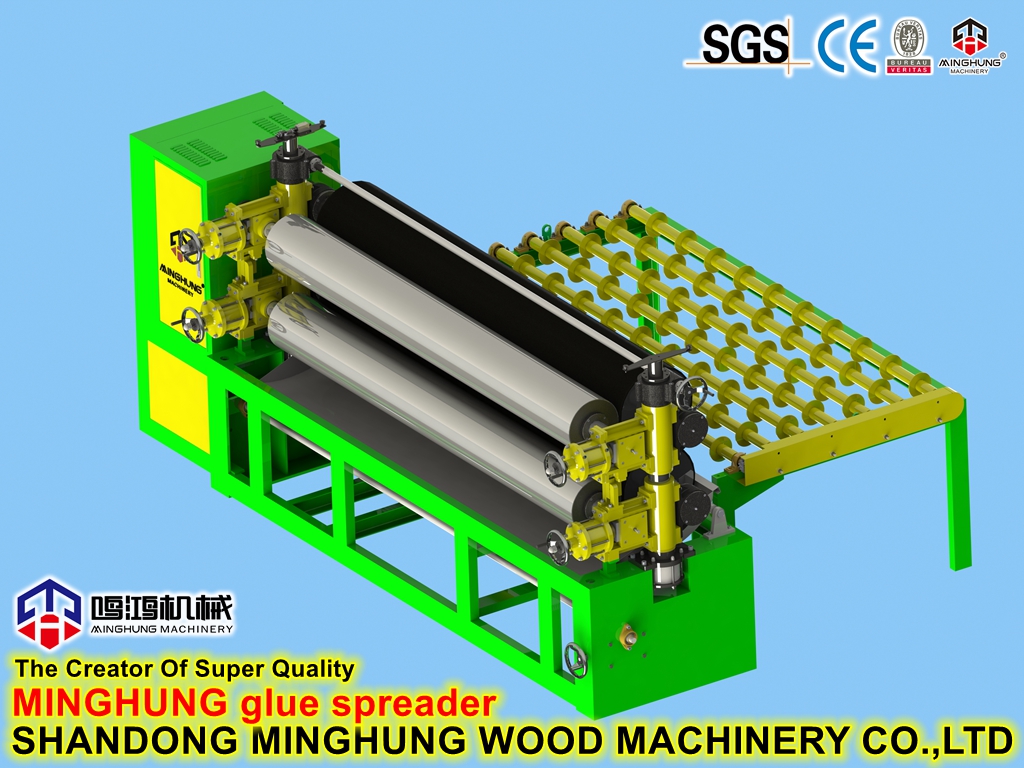

Automatic Glue Spreader: Uses a four-roll spreader or curtain coater to apply the formaldehyde-free adhesive evenly and quantitatively to the veneer surface. Precise control of the glue spread is key to minimizing waste and ensuring bond quality.

Layup Line (Assembling Line): Includes automatic veneer feeders, layup machines, and a pre-press. The dried and glued veneers are stacked here (manually or automatically) into the required number of layers and structure (mat), which is then initially cold-pressed to give it initial shape for easier handling and hot pressing.

| 3. Hot Pressing Section Equipment |

Hot Press: This is the core equipment of the production line. It presses the assembled mat under high temperature and pressure to form a solid panel.

For formaldehyde-free glues (especially PU glue), a multi-opening hot press with venting capabilities or a continuous press is typically required. The press platens have vent holes to allow steam and volatiles to escape during pressing, preventing blistering and delamination.

The equipment must have precise temperature, pressure, and time control systems to meet the specific curing requirements of different formaldehyde-free adhesives.

| 4. Finishing Section Equipment |

Cooling and Turning Device: Cools and turns the high-temperature panels after hot pressing to prevent deformation caused by stress concentration.

Curing Storage (Seasoning Area): Not traditional machinery, but absolutely critical. After cooling, panels need to rest in a constant temperature and humidity environment (curing/seasoning). This allows the formaldehyde-free adhesive to fully cure and internal stresses to relax, stabilizing the panel's moisture content and physical properties, significantly reducing the risk of future warping.

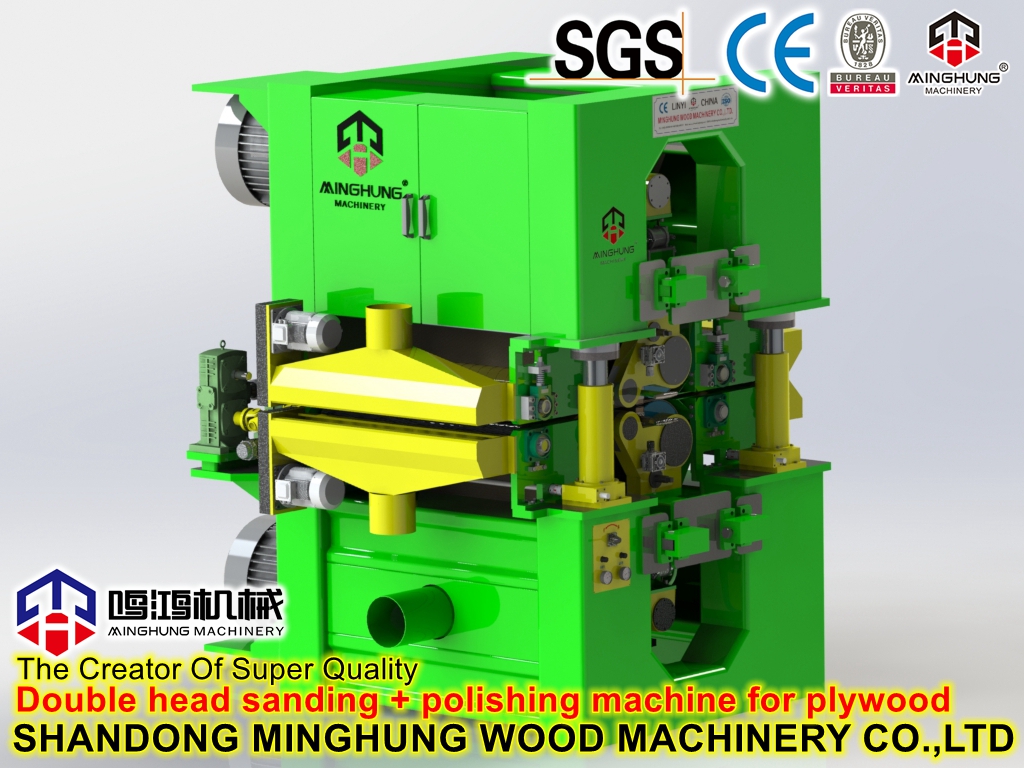

Calibrating Sander: Includes a double-sided calibrating sander and a fine sander. First, the panel is sanded to a precise and consistent thickness across its entire surface; then, fine sanding is performed to eliminate imperfections and achieve a smooth, flat surface, providing a perfect substrate for subsequent laminating or painting.

Panel Saw / Cross-Cut and Rip Saws: Precisely trims the four edges of the panel to standard dimensions.

sander

cross-cut saw

| 5. Quality Control and Auxiliary Equipment |

Plant-Wide Dust Collection System: An efficient central dust collection system is essential throughout the entire production line (from peeling, cutting to sanding) to maintain a clean production environment, reduce surface defects, and meet environmental requirements.

Laboratory Equipment: An inline quality control lab needs equipment such as a Formaldehyde Test Chamber, universal testing machine (for testing bond strength and MOR), moisture content meter, etc., to ensure every batch of products complies with NAF standards and physical performance indicators.

Production Line Characteristics Summary:

This production line is highly automated and continuous, emphasizing a clean production environment and precise control of process parameters. Compared to traditional formaldehyde-based plywood lines, its core differences lie in: the glue application and preparation system suitable for formaldehyde-free adhesives, the hot press with venting capabilities, and the more critical panel curing process.

Common Specifications and Sizes

| 1. Common Thickness |

Due to structural and safety requirements, the thickness range used for baby furniture is relatively focused.

3mm, 4mm: Commonly used for non-load-bearing or low-load parts such as drawer bottoms and cabinet backs.

5mm, 6mm, 9mm: This is the most commonly used thickness range. Widely used for main components like crib side panels, headboards, drawer sides, and cabinet bodies, offering a balance of lightweight and sufficient strength.

12mm, 15mm, 18mm: Mainly used for key parts requiring high load-bearing capacity and strong support, such as crib mattress platforms (needing to support the mattress and baby's weight), table tops, shelves, and table legs.

25mm and above: Less common for baby furniture, unless for particularly thick table tops or special structural designs.

| 2. Common Dimensions (Panel Size) |

The imperial is the most mainstream and universal size in the international market, though metric sizes are also common.

Standard Size (Most Common):

4 feet x 8 feet (Often written as 4' x 8')

Metric Equivalent: 1220 millimeters x 2440 millimeters

This is the benchmark size for global sourcing and production, offering the highest utilization rate and the most competitive price.

Other Common Sizes:

4 feet x 6 feet (4' x 6') / 1220mm x 1830mm

3 feet x 6 feet (3' x 6') / 915mm x 1830mm

5 feet x 6 feet (5' x 6') / 1525mm x 1830mm (Less common)

| 3. Core Structure |

All Poplar Core: Uniform texture, moderately soft and hard, good flatness. A common choice for baby furniture.

Poplar + Eucalyptus (or Hardwood) Mixed Core: Combines the flatness of poplar with the hardness of eucalyptus, resulting in higher structural strength.

All Birch Core: Highest strength, high density, excellent load-bearing performance and screw-holding capacity. Often used for critical load-bearing parts in high-end baby furniture. Also the most expensive.

| 4. Grade & Surface Finish |

Grade: Refers to the surface quality of the face and back veneers.

Common Combinations: BB/CC, AB/BB, AA/BB. Baby furniture usually requires higher face grades (e.g., Grade B and above) to ensure a smooth surface without large knots or defects, facilitating high-quality painting.

Surface Finish:

Unfinished (Sanded): Provides a sanded smooth surface for the furniture manufacturer to paint and finish themselves.

Melamine Laminated: Pre-laminated with decorative paper in various colors (e.g., pure white, cream white, wood grain). It is wear-resistant and easy to clean, and can be used directly for cabinet interiors, saving downstream processing costs.