Melamine Plywood Hot Press Machine with Stainless Thick Steel Plates  Hydraulic Melamine Hot Press Machine

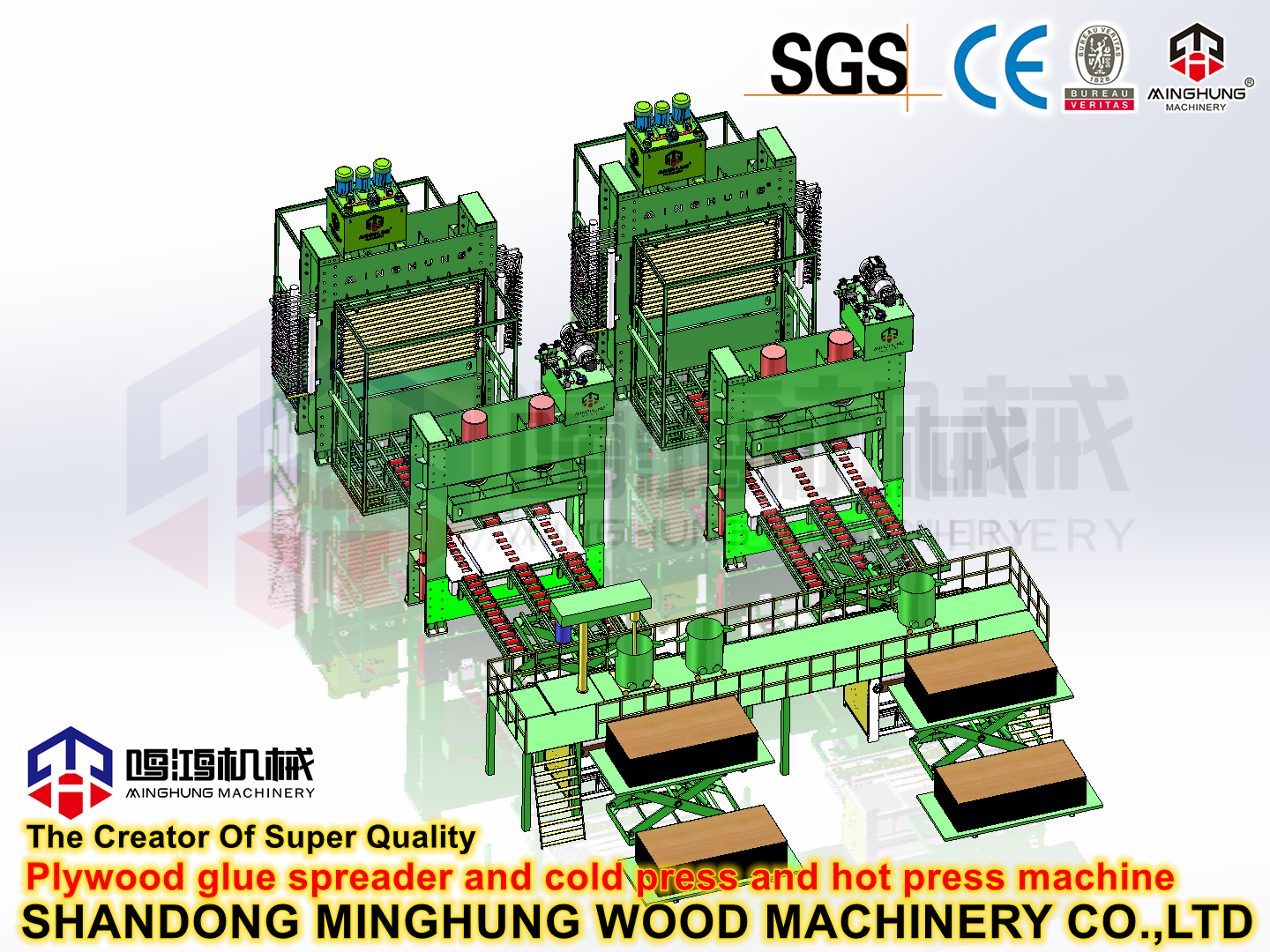

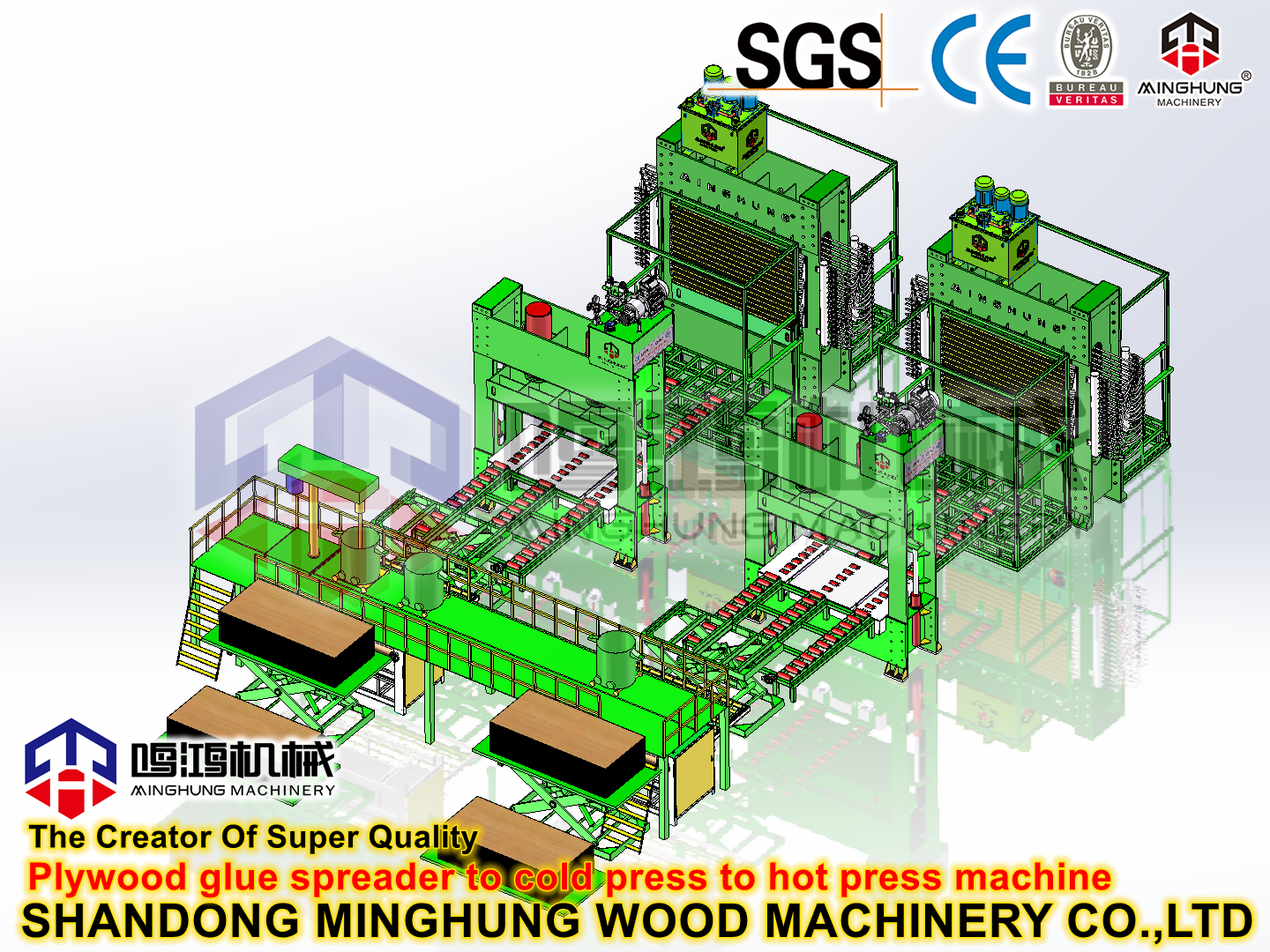

Hydraulic Melamine Hot Press Machine Producing kinds of plywood, like furniture plywood, construction plywood, marine plywood, hydraulic hot press machine is the necessary and important machine.

And if you produce construction plywood, need laminating melamine on the surface of plywood. it will require hot press pressure bigger, so usually 800t melamine hot press machine is ok and enough, the pressing effect is very good.

Hot Press's structure not complex, mainly consist of: the machine frame, hot plates, hydraulic station, cylinder.

It can be different pressure and layers according to the real conditions, like 500t, 600t, 800t, 1000t, 1200t. 8layers, 10layers, 12layers, 15layers, 20layers, 25layers

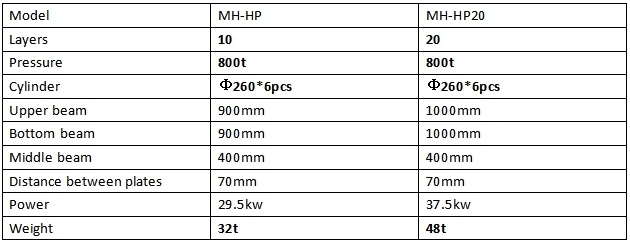

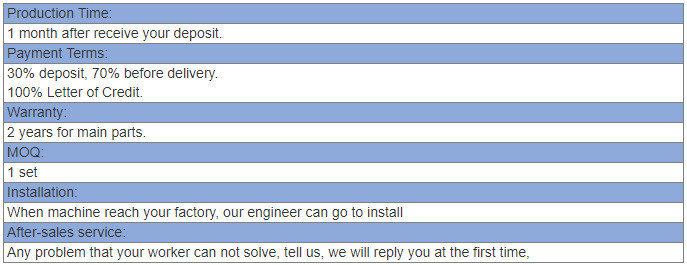

>>>Specification:

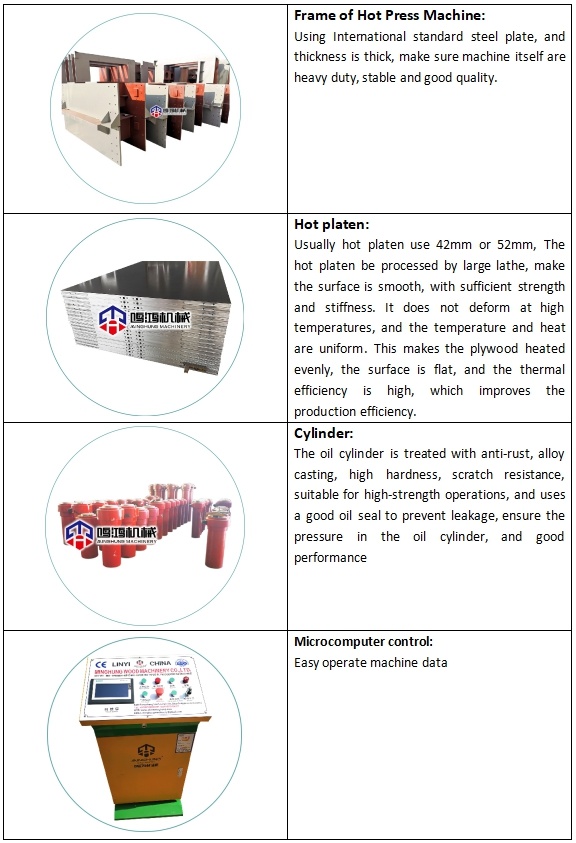

>>>Main Parts:

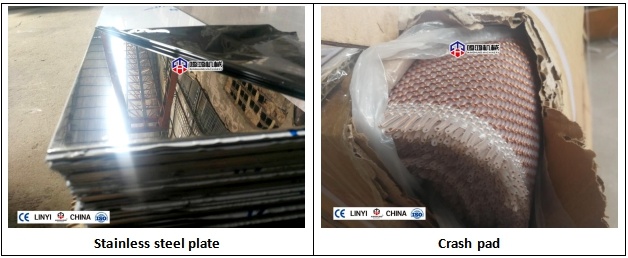

Press melamine on plywood, for prevent the melamine stick to the hot platen, so need stainless steel plate and crash pad, then when worker put plywood with melamine into hot press machine, will be very easy, and will not damage the melamine.

>>>Hot press in client factory:

For convenient loading, hot press machine's frame is combined, and use international standard steel plate, make sure hot press weight is very heavy, stable and good quality.

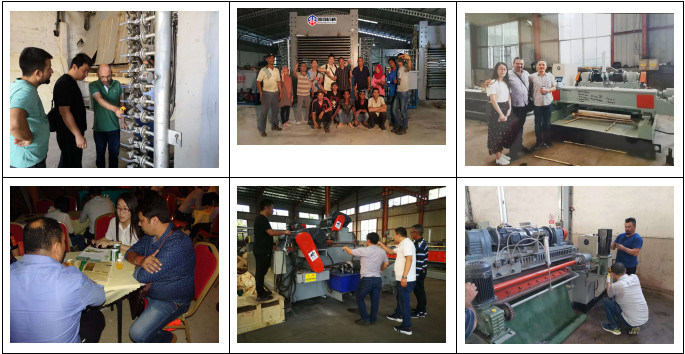

When plywood press machine and other plywood machine reach your factory, our engineer will go to install and teach your worker how to operate and maintain machine.

And in the future, when your worker meet any problem, or your factory need purchase some spare parts of plywood machine, we will help you solve and help you buy.

>>>Us

Our factory main products include wood log debarker, veneer peeling machine, vacuum veneer stacker, veneer dryer machine, plywood cold press machine, plywood hot press machine, glue spreader, glue mixing machine, automatic plywood veneer paving line, plywood saw machine, sanding machine.

Scientific and technological innovation oriented, quality-based, service supremacy, we offer full complete range of plywood production solution and technology support for our customers. Yet our machines have been exported more than 30 countries and regions like Russia, Poland, Ukraine, Portugal, Bulgaria, Romania, Turkey, Egypt, Morocco, Indonesia, etc, and get good feedback.

With high efficiency sales team offer 24 hours online service, the professional technical team and after-sales service team offer plant layout, machine drawings, and after-sales service.

Choose us, you need not worry anything, we will help you arrange all.

What we want is try our best help your business create much value.

>>>Delivery:

1> When loading, we will share the loading pictures of plywood press machine with you.

2> When ship leave, we will offer the container and ship information for you.

3> Offer all documents which for your custom clearance.

we produce the full line of plywood machine.

wood debarker, veneer peeling machine, vacuum veneer stacker, veneer dryer machine include veneer press dryer and roller dryer, plywood cold press machine, plywood hot press machine, glue spreader, glue mixing machine, automatic plywood veneer paving line, plywood saw machine, sanding machine.

>>>Related Plywood Machine:

>>>RFQ

>>>Contact us:

whatsapp/telegram: +8618769900191 +8615589105786 +8615805493072

Website: www.plywoodmachineline.com

Email: minghungmachinery@gmail.com