Salient Features and Advantages

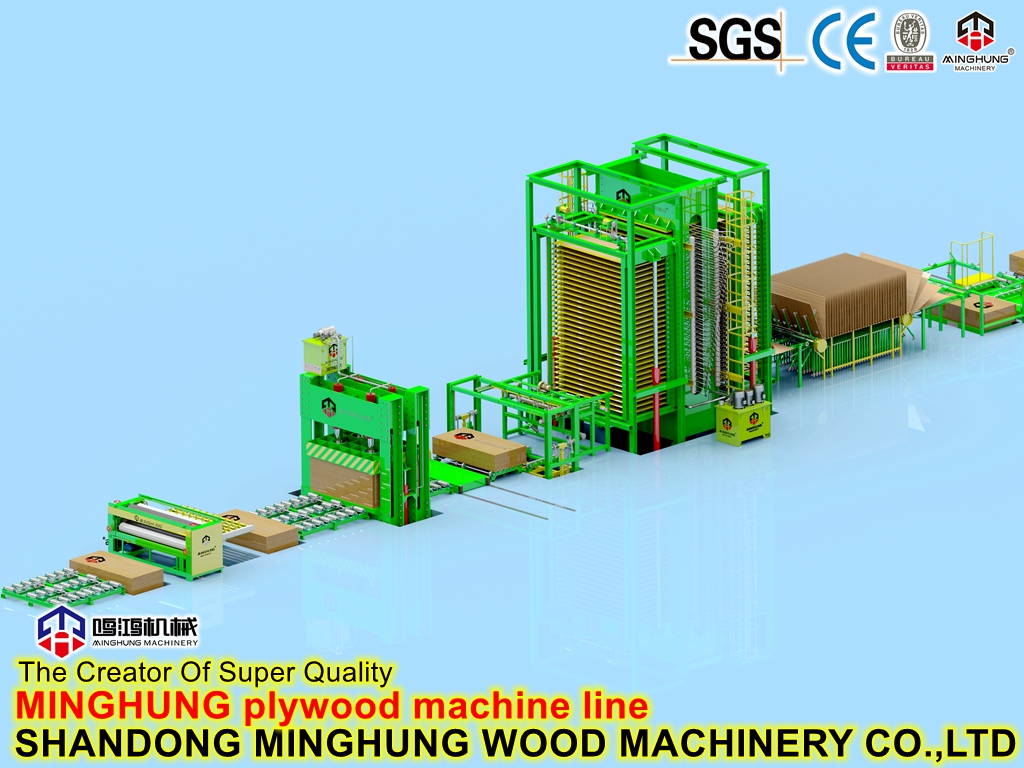

High Efficiency and Continuous Production: Operates 24/7 uninterrupted, with production efficiency far exceeding that of traditional intermittent drying kilns, perfectly matching the rhythm of automated production lines.

Excellent Drying Quality: Uniform hot air circulation ensures consistent heating of the plywood, leading to even drying throughout the inner and outer layers. This effectively prevents defects such as deformation, cracking, and blistering, significantly improving product yield.

Energy Saving and Environmental Protection: The sealed circulation and efficient insulation design ensure high thermal efficiency. Precise humidity control minimizes heat waste. It can save 30%-50% energy compared to traditional kilns.

High Degree of Automation: The entire process is controlled by PLC. Simply set the parameters, and the entire drying process completes automatically, greatly reducing reliance on operator experience and labor intensity.

Space Saving: The multi-layer mesh belt design (typically 3-5 layers) achieves massive drying capacity with a relatively small footprint.

Improved Working Environment: Integrated equipment operation improves the high-temperature and high-humidity production environment of the workshop.

Even Heating: Multi-layer mesh belt design ensures both sides of the plywood are heated uniformly, preventing deformation and cracking.

Intelligent Control: PLC touchscreen control system allows preset drying curves and real-time monitoring of temperature and humidity.

Durable Structure: High-temperature resistant stainless steel mesh belt ensures long equipment life and easy maintenance.

This equipment is not only suitable for plywood but also widely used for drying various types of wood-based panels:Plywood Production, Blockboard Production, Fiberboard (MDF) Production,Particleboard Production,Decorative Panel (Overlay) Production,Drying of Substrates for Engineered Wood Flooring,Other sheet-shaped wooden or non-wooden materials requiring continuous drying.

Drying Temperature Range: 50℃-180℃

Mesh Belt Width: 1.2m-2.5m (Customizable)

Drying Time: 10-60 minutes (Adjustable)

Heating Methods: Electric/Steam/Gas Heating (Optional)

Power: Customized based on equipment size

Transmission speed: 1-17m/min

Drying capacity: 55-60m³/20h

In conclusion, the Mesh Belt Continuous Conveyor Plywood Dryer is an indispensable core piece of equipment in the modern plywood industry. Investing in it is of long-term significance for enterprises to improve product quality, reduce production costs, and enhance market competitiveness.

We offer installation and commissioning, operation training, as well as lifetime technical support. Equipment warranty one year.

If interested please contact us for a quote.

Our contacts:

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com