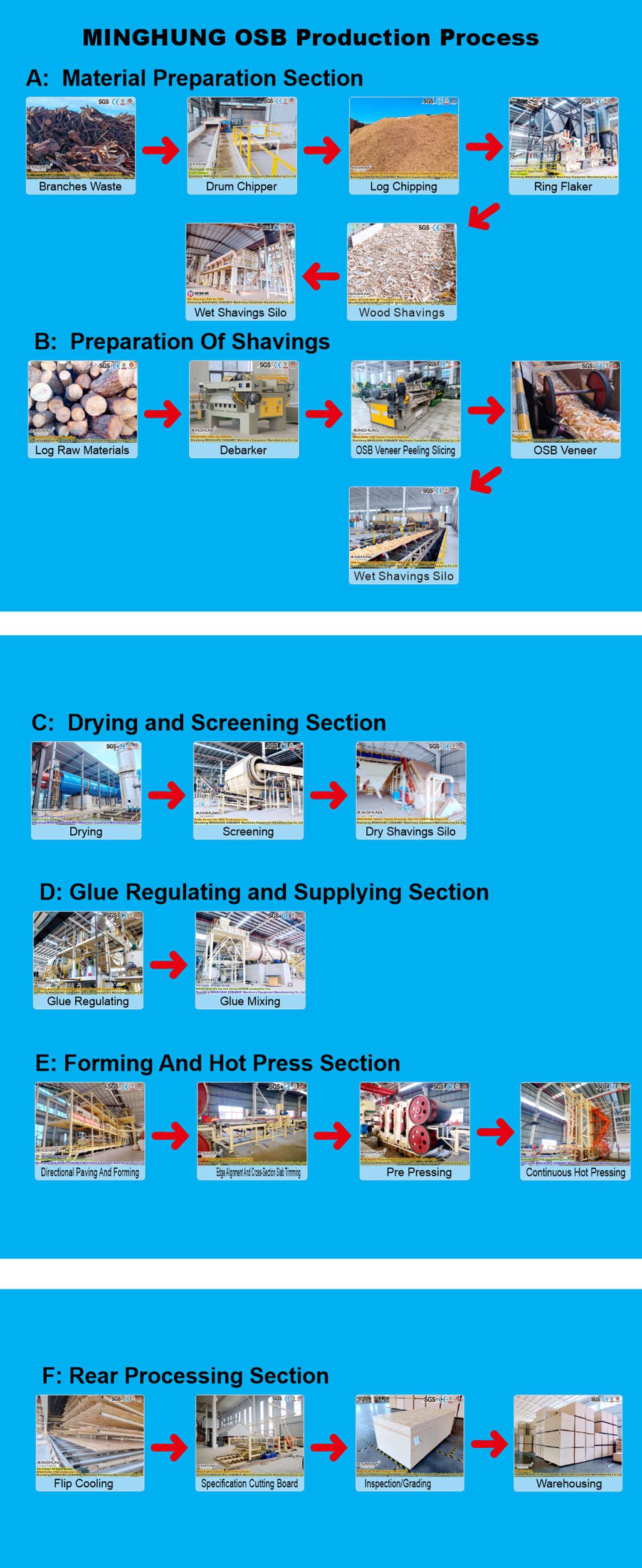

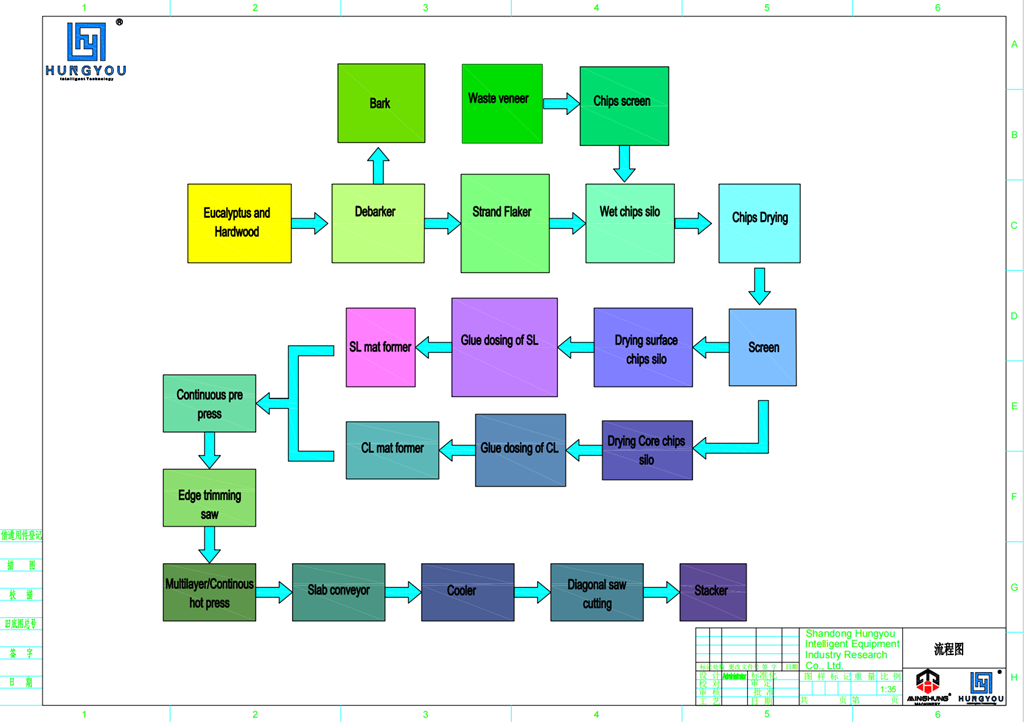

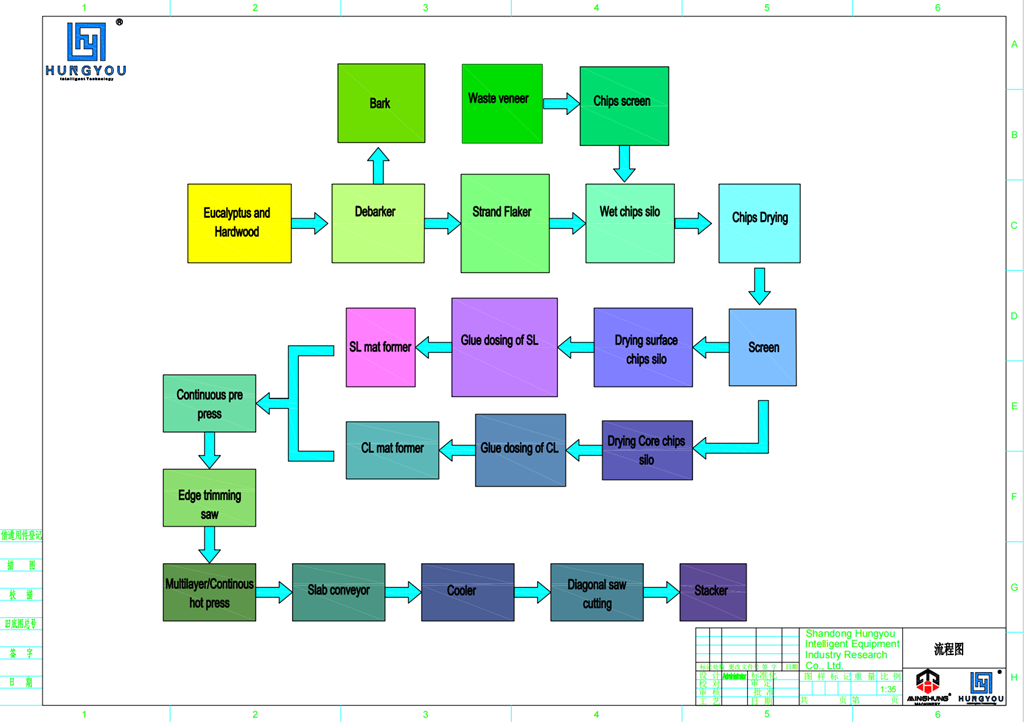

1. Raw Material Preparation: The production line typically uses fast-growing woods like pine . Logs are processed into chips by a drum chipper and then flaked into strands of specific dimensions (usually 40-120mm long, 5-20mm wide, 0.3-0.7mm thick) by a flaker . This step ensures the strand morphology, laying the foundation for the high strength of the board .

2. Drying and Glue Blending: The moisture content of the dried strands needs to be precisely controlled to around 2%-4% . Glue blending is the core step for achieving CARB certification. To ensure extremely low formaldehyde emissions, the production line must use formaldehyde-free adhesives such as MDI (diphenylmethane diisocyanate) eco-adhesive . An advanced ring blender ensures the MDI adhesive uniformly coats the strand surfaces.

3. Oriented Forming and Hot Pressing: This is the key step that reflects the "oriented" structural characteristics of OSB. The glued strands are laid by an oriented former, with surface strands aligned longitudinally along the panel's length and core strands aligned transversely or randomly, forming a three-layer oriented structure . This structure reorganizes the wood grain, giving the panel high dimensional stability and bending strength . Hot pressing often uses a continuous flat press to form the mat under high temperature and pressure. For an 18mm thickness, the pressing parameters (temperature, pressure, time) must be precisely controlled to ensure uniform density and structural stability .

4. Finishing and Quality Control: The pressed panels undergo cooling, trimming, and sanding to ensure precise dimensions and a smooth surface . The final quality control step is crucial. Products must pass strict tests to ensure their formaldehyde emission meets the stringent CARB Phase 2 standard (e.g., <0.09ppm) before they can be packaged and shipped.

Main Application Scenarios

Thanks to excellent environmental performance (due to MDI adhesive) and sturdy physical properties (due to the oriented structure), CARB-certified 18mm OSB boards have a wide range of applications.

Application Sector | Specific Use Cases | Core Advantages |

Building Structure | Wall panels, floor panels, roof panels in wood-frame buildings ; Concrete formwork | High strength, good load-bearing capacity, dimensional stability |

Interior Decoration & Furniture | Kitchen/bathroom cabinets, partitions, feature walls ; Furniture frames, large storage cabinets | Excellent moisture resistance, strong nail-holding capacity, easy to work with (saw, nail, veneer), environmentally safe |

Packaging & Transport | Export packaging cases (often exempt from inspection), pallets, large crates | Impact resistance, moisture resistance, exempt from quarantine treatment |

Other Fields | Exhibition systems, warehouse shelving | Cost-effective, easy to customize and process |

In summary, the CARB-certified 18mm OSB production line not only ensures the product's outstanding physical properties but also guarantees its excellent environmental quality through strict control of raw materials (like MDI adhesive) and processes . This makes the final product an ideal choice for applications demanding high environmental and strength standards.

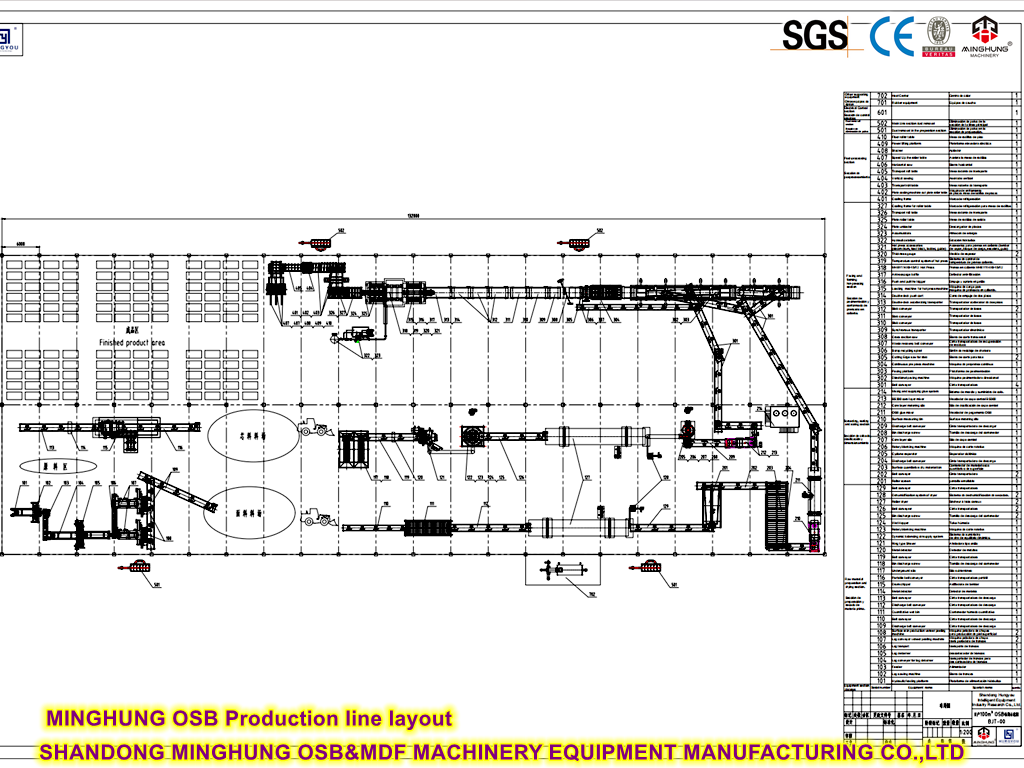

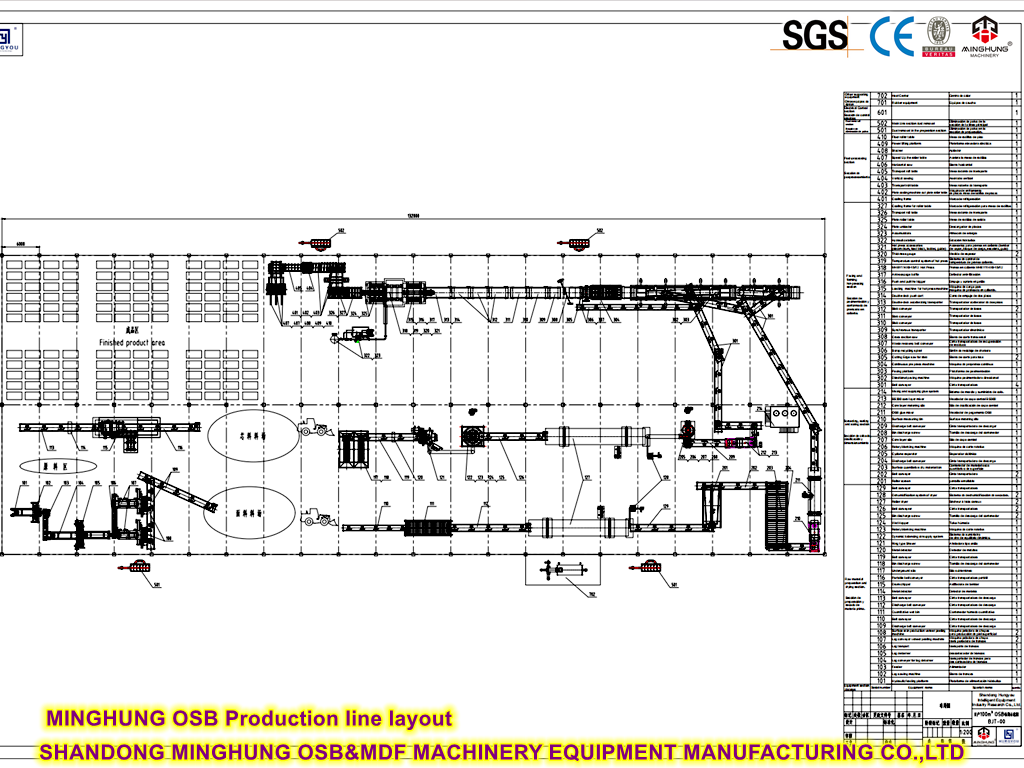

Claim Your Free OSB Line Layout! Get end-to-end plant design from strand preparation to sanding. Receive 3D factory plan within 30 days.

Our contacts:

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com