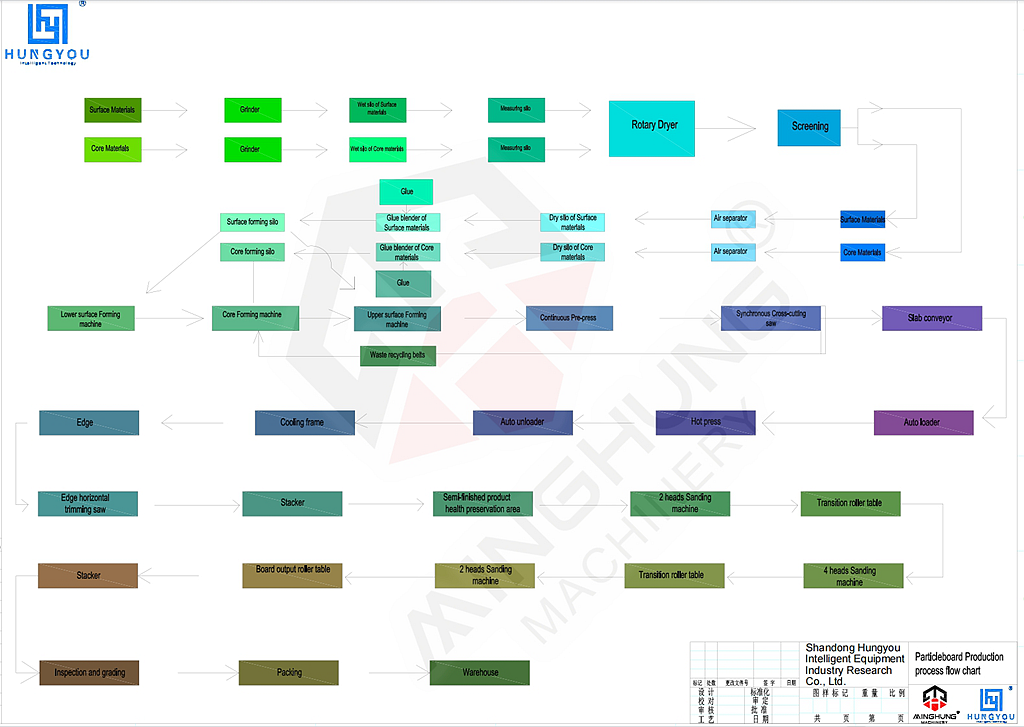

Core Production Equipment

1. Straw Bale Breaking & Coarse Shredding System

Function: Breaks straw bales, shreds to 50-100mm fragments, removes soil/metallic impurities.

Key Equipment:

Heavy-duty Chain Conveyor: Capacity 20 tons/hr, wear-resistant design;

Dual-Shaft Shredder: Power 160kW, Hardox 500 blades (HRC 58-62), anti-wrapping structure;

Magnetic Separator: Magnetic field ≥12,000 Gauss.

Straw Specificity: Enhanced impurity removal (soil content 8-15%, higher than wood).

2. Fine Grinding & Fiber Activation Unit

Function: Refines particles to target size (20-50mm length, 0.2-0.5mm thickness), steam-softens wax layer.

Key Equipment:

Hammer Mill: Speed 2,800 rpm, Φ8mm screen (custom anti-clog design);

Steam Pre-treatment Vessel: Pressure 0.6MPa, temp. 160°C, residence time 3-5 min (disrupts silica layer for better bonding).

Capacity: ≥12 tons/hr (dry basis) for continuous feeding.

3. Rotary Drying System

Function: Reduces moisture content from 35-50% to ≤8%.

Core Equipment:

Triple-Pass Rotary Dryer: Φ3.2m diameter × 24m length, hot air 180-220°C;

Biomass Hot Air Furnace: Fueled by straw fines, thermal efficiency ≥85%;

Cyclone + Wet ESP: Dust emission ≤20mg/m³ (EU standard).

Energy Saving: Exhaust heat recovery reduces energy use by 40% vs. wood drying.

4. MDI Blending & Forming System

Function: Precise MDI resin application (4-5%), forms uniform mat.

Key Equipment:

High-Pressure Resin Blender: Resin droplet size ≤50μm, application error ±0.3%;

Air-Flow Forming Machine: Speed 80m/min, density deviation ≤±3% (laser monitoring);

Wax Dispensing Unit: Wax melting temp. 90°C, dosage 0.8-1.2% (waterproofing).

Straw Adaptation: Optimized spray angles overcome hydrophobic surface.

glue mixer for PB/Chipboard

glue mixer for PB/Chipboard

mat forming machine

5. Continuous Press

Function: Cures mat under heat/pressure into stable boards.

Core Equipment:

Continuous Press:

Width 2.7m, length 30m;

Pressure gradient control (3.0→0.5MPa);

Temp. 200±5°C, thickness range 8-40mm;

Line speed 800mm/s (18mm board).

Advantage: Hydraulic servo closed-loop control optimizes density gradient.

6. Finishing Line

Function: Cooling, trimming, and surface finishing.

Equipment | Parameters & Function |

Roller Cooler | Cooling time ≥25 min (stress relief) |

Double-End Trimmer | Cutting accuracy ±0.5mm, power 55kW×2 |

4-Head Calibrating Sander | Sanding depth 0.1-1.5mm, grit sequence P60→P120→P180→P240 |

Automated Stacking Robot | Stack height 1.8m, positioning accuracy ±1mm |

edge cutting sawing machine

sander

7. Emission Control System

Function: Treats dust/VOCs from production.

Key Units:

Central Dust Collector: Airflow 120,000m³/h, filtration precision 0.1μm (PTFE membrane);

RTO (Regenerative Thermal Oxidizer): VOCs removal ≥99%, gas consumption ≤80m³/h;

Wet Scrubber: Treats press exhaust with pH auto-adjustment.

Global Straw Sources & Advantages

Key Regions: China (Hubei/Jiangsu/Heilongjiang: 200-220M tons), USA (200-250M tons), EU (Belgium/Germany: ~4M tons);

Supply Advantages: Rice straw costs 30% less than wood; ≤50km collection radius controls logistics; low ash (5.2%) enhances glue bonding.

Eco-Performance: Zero formaldehyde (MDI technology), CARB/EPA certified;

Physical Strength: MOR ≥14MPa, IB ≥0.45N/mm², density customizable (0.4-0.8g/cm³);

Functionality: Water absorption ≤12% (24h immersion), sound absorption coefficient 0.6 (30% better than wood);

Workability: Optimized pre-drilling parameters for dowel joints reduce edge chipping.

Furniture: Cabinet bodies, tabletops (formaldehyde-free safety);

Construction: Acoustic wall panels/ceilings (0.4-0.6g/cm³ grades);

Packaging: Machinery pallets (water-resistant);

Interior Decor: Floor underlay, door cores (cost-effective MDF alternative).

Shandong MINGHUNG Wood Based Panel Machinery Co.,Ltd Located in Xiaogezhuang Industrial Zone, Yitang Town, Lanshan District, Linyi City.

MINGHUNG company provides a complete set of process design, electrical design and manufacturing, We can provide one-stop complete factory solutions for wood-based panel customers. MINGHUNG product series include medium density fiberboard (MDF), high density fiberboard (HDF), particle board (PB), oriented strand board (OSB), veneerable super strong particle board (LSB) multi-layer heat press production line, double-sided fixed thickness broadband Sanding machine, gauge saw, mechanical paving machine, air flow paving machine, channel dryer, super screen, post-processing system artificial panel cooling system, turning machine, stacker, storage and transportation trolley. etc. For artificial panel equipment mainly involved in particleboard, medium density fiberboard, oriented strand board, multilayer plywood machinery.

We regularly participate in international industry exhibitions based on the company's business development and customer needs. On one hand, this helps us showcase our company's strength and expand new customers. On the other hand, we visit existing customers for follow-up visits, thereby enhancing the bond between them.

Upgrade your production line now!

We provide global installation support and technical training, 1-year machine warranty, and 24-hour online response - let your Particleboard production enter a new era of intelligence and low carbonization.

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com

glue mixer for PB/Chipboard

glue mixer for PB/Chipboard