|

Machinery Equipment

A complete, high-output OSB production line with a daily capacity of 800 cubic meters is a complex system integrating various specialized machinery. The following is an introduction to the core equipment, arranged according to the production process:

1. Raw Material Preparation Section

Debarker: Used to remove the bark from logs. Bark can impair the bonding quality and appearance of the board and must be removed first. The equipment typically employs drum or ring designs for efficient, continuous, high-volume debarking.

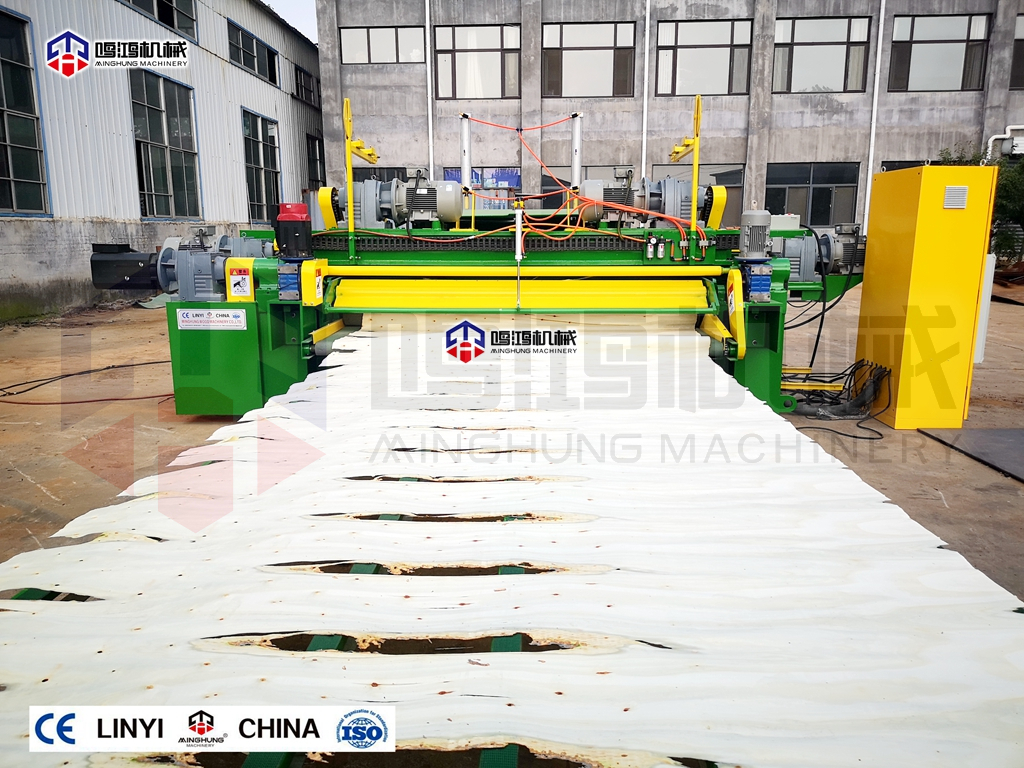

Flaker/Strander: A core piece of equipment for OSB production, it processes logs or wood chips into strands (flakes) of specific dimensions. Equipped with a powerful disc knife and bed knife, it produces uniform strands of consistent length and thickness by adjusting the knife gap and cutting angle. This is fundamental for ensuring the strength and quality of the final OSB panel.

Strang Breaker/Hammer Mill: Used for secondary reduction of oversized or irregular strands to produce satisfactory fine face strands and coarse core strands. It adjusts strand size through hammering or grinding, ensuring the strand morphology meets the requirements for oriented forming.

2. Drying and Screening Section

Rotary Drum Dryer: Utilizes high-temperature hot air to efficiently and uniformly dry the wet strands inside a rotating drum. This large equipment features internal flighters to ensure full contact between strands and hot air, precisely reducing the moisture content to the required level for subsequent gluing and pressing.

Vibrating Screen/Pneumatic Classifier: Used to grade the dried strands by size. Through multi-layer screens with different mesh sizes or using air flow as a medium, it precisely separates strands into fine face fractions and coarse core fractions, while removing excess dust. This ensures uniform strand size for each layer during forming, optimizing panel properties.

3. Blending and Forming Section

Ring Blender: Used to uniformly mix strands with resin, wax, and other additives. This equipment uses high-speed rotating mixing arms to coat each strand surface with a consistent layer of resin in a very short time. It offers high mixing efficiency and minimizes resin waste. Multiple blenders are typically used for face and core strands separately.

Mechanical Oriented Forming Station: The signature equipment of an OSB line. It utilizes a series of rotating at a constant speed mechanical spreading heads to orient and spread the face strands along the production line direction (panel length direction), while the core strands are spread randomly. By precisely controlling the speed and direction of the spreading heads, it creates a uniform, multi-layered mat with an oriented structure, which is the source of the anisotropic strength properties of OSB panels.

4. Pressing and Finishing Section

Continuous Belt Pre-Press: Applies preliminary compression to the fluffy mat before it enters the hot press. It holds the mat between upper and lower steel belts and applies pressure to pre-compact it, reducing thickness and increasing density. This facilitates handling and transport into the press and prevents the mat from being blown apart.

Cooler and Star Cooler: Cools the high-temperature panels exiting the hot press. Panels are stood on edge and spaced on a rack, where forced circulation of cool air rapidly reduces their temperature. This stops the thermo-chemical reactions, preventing warping or blistering due to residual heat, and stabilizes the internal stresses of the panels.

Cross-Cut and Rip Saws (Size Saw): Used to cut the cooled large-format panels into standard market sizes (e.g., 1220mm x 2440mm). The equipment usually includes cross-cutting and ripping units controlled by high-precision servo systems to ensure accurate dimensions, minimal diagonal error, and smooth, clean edges.

5. Auxiliary Systems

Energy Plant (Thermal Oil System): Provides the necessary heat for the dryer and hot press. It is typically a bio-mass energy system fueled by process waste (bark, sander dust, etc.), including a boiler, dust removal, and heat transfer systems, enabling energy self-sufficiency and environmentally friendly production.

Dust Extraction System: A network throughout the production facility, comprising ducts, fans, and collectors (e.g., baghouse filters). It collects wood particles and dust from various process points, ensuring a clean production environment, preventing dust explosions, and recovering combustible material for the energy center.

Central Control System: The "brain" of the production line. It uses advanced PLCs and industrial computers for fully automated monitoring and adjustment of the entire process. Operators can set and modify parameters via the HMI (Human-Machine Interface), while the system automatically controls equipment operation to ensure stable, efficient production and enable quality data tracing.

|

High Stability OSB

1. What is High-Stability OSB?

High-Stability OSB (Oriented Strand Board) is an upgraded engineered wood panel manufactured through specialized processes and high-end adhesives. It not only retains the high strength, bending resistance, and anti-deformation capabilities of traditional OSB but also significantly improves in water resistance, moisture-proofness, dimensional stability, and creep resistance through technological innovation. This allows it to maintain excellent structural integrity and shape stability even in harsh environments (e.g., high humidity, temperature fluctuations).

2. Key Characteristics:

Exceptional Dimensional Stability: The special oriented strand structure and high-performance adhesives greatly reduce the rate of moisture expansion and contraction under varying humidity and temperature, effectively preventing warping and deformation.

Enhanced Moisture and Water Resistance: The use of waterproof-grade resins like Isocyanate (MDI) glue gives the panels superior moisture and water resistance, even meeting the requirements for exterior applications.

High Internal Bond Strength: Advanced hot-pressing technology ensures thorough curing and bonding between the adhesive and strands. The panel's internal structure is dense and cohesive, resisting delamination, and offers outstanding load-bearing capacity and screw-holding power.

Long-Lasting Creep Resistance: Its ability to resist slow deformation under sustained long-term load (creep resistance) is far superior to ordinary OSB and some wood-based panels, ensuring the long-term safety of building structures.

Eco-Friendly and Safe: High-quality OSB production lines strictly control raw materials and adhesives. The final product complies with international environmental standards (e.g., CARB P2, EPA TSCA Title VI, F★★★★), with very low formaldehyde emissions.

|

Main Applications

The 1220mm x 2440mm (4ft x 8ft) size is a globally accepted standard dimension, making high-stability OSB widely applicable, especially in performance-demanding fields:

Building Structural Materials: Used as roof sheathing, wall sheathing, and floor underlayment (subflooring), providing robust structural support for wood-frame construction.

Container Flooring: An ideal material for manufacturing freight container flooring due to its high strength, impact resistance, and excellent creep resistance.

Exterior Applications: With special treatment, it can be used for exterior applications such as concrete formwork, shed lining, and signboard substrates.

High-Performance Furniture & Decoration: Used for custom cabinet casings, shelving, workbench substrates, and other areas requiring load-bearing capacity and moisture resistance.

Industrial & Logistics: Used to manufacture pallets, warehouse shelving partitions, and large crates.

|

Introduction to the 800m³/Day production Capaticy

An OSB production line with a daily output of 800 cubic meters represents a large-scale, highly efficient, industrial-grade top-tier manufacturing level.

Mass Production: A daily output of 800m³ translates to an annual production capacity of approximately 250,000 cubic meters (based on 310 working days per year), capable of meeting the demands of large-scale projects and continuous high-volume orders.

Economic Benefits: Such high capacity brings significant economies of scale, effectively reducing the per-unit production cost and making the product highly price-competitive in the market.

Advanced Technology & Automation: Achieving this capacity necessitates highly automated and continuous production equipment. From raw material processing to final cutting, the entire line is precisely coordinated by a central control system, ensuring 24/7 stable operation and maximized production efficiency.

Quality Consistency: High-capacity production lines are typically equipped with more precise process control and quality inspection systems, ensuring that every panel maintains high consistency and stability in quality while being produced at high speed, meeting all design standards.

Market Supply Capability: The massive daily output means the supplier has the capability to respond quickly to large clients' procurement needs, guaranteeing a stable supply and timely delivery, positioning them as a reliable partner.

|

Comment & FAQ

1.Q:What can you purchase from us?

A:Particle board production line, directional particle board production line, medium/high fiber board production line, hot press, preforming press machine, plywood production line, automatic production line for hot press, veneer dryer, hot press, cold press machine and other woodworking machinery.

2.Q:How long the production time?

A:If one set machine,3-4 months;If the full production line 6-8 months.

3.Q:What are your advantages?

A:We have rich experience in the market, with the same cost, we do better because we have strict control of the production process. We have an independent inspection department to check the quality.

4.Q:How is your quality?

A:As an experienced manufacturer, the quality of our machines can be guaranteed and we have supplied our products to thousands of customers all over the world.

5.Q:What payment methods do you offer?

A:Usually T/T and LC. If you have other payment methods, we can also consider it.

|

Company Profile

Shandong MingHung OSB&MDF Machinery Equipment is a China professional factory who specilize in manufacturering and offering Wood based panel machine, including OSB making machine, MDF making machine, and Chipboard /PB making machine.

Our factory with the advanced processing lathes, Mature production technology, and Professional engineers and technicians, and independent ability of reasearch and development, and quickly service, ensure that we have the ability to offer you the suitable and good woodworking machinery as different conditions and requires.

|

Packing & shipping

|

Certifications

|

Exhibtion

We regularly participate in international industry exhibitions based on the company's business development and customer needs. On one hand, this helps us showcase our company's strength and expand new customers. On the other hand, we visit existing customers for follow-up visits, thereby enhancing the bond between them.

Claim Your Free OSB Line Layout! Get end-to-end plant design from strand preparation to sanding. Receive 3D factory plan within 30 days.