1. Raw Material Pretreatment

Retardant-Resin Mixing: Liquid flame retardant (e.g., ammonium polyphosphate) is precisely blended with resin at 12~18% of board weight, then uniformly coated on wood fibers via high-pressure spraying.

Fiber Drying: The mixture is rapidly dried at 120~150℃, controlling moisture content to 8±0.5% to prevent steam explosion during pressing.

glue mixer

fiber drying machine

2. Mat Forming & Pre-pressing

Fibers are air-laid into a mat and pre-compressed at 5~8 MPa to evacuate air, forming a preliminary slab.

mat forming machine

pre press

3. Continuous Hot-Pressing Core Stage

High-Temp Activation Zone (Entry Section):

The slab enters the initial press section with upper/lower steel belts moving at 600~1000 mm/s.

Platens heat to 250~280℃ within 30 seconds, triggering retardant decomposition.

High-Pressure Curing Zone (Core Section):

Pressure rises to 12~18 MPa with dwell time >120 seconds, forcing molten retardant into fiber pores.

Negative-Pressure Detoxification (-0.05 MPa) simultaneously extracts toxic gases (e.g., PH₃, HCN).

Gradient Cooling Zone (Exit Section):

Three-stage cooling: 200℃ → 120℃ → 80℃ at a rate ≤15℃/min to prevent surface cracking.

4. Post-Curing Treatment

Boards enter a 120~150℃ curing oven for 20~30 minutes to complete retardant crosslinking, forming a stable carbonized fireproof layer.

5. Quality Reinforcement

Online infrared scanners detect and mark areas with density deviation >±3% or temperature anomalies for rework.

Flame resistance sampling: EN13501-1 vertical burn tests conducted every 30 minutes.

Core Mechanism:

The synergy of retardant activation at 280℃, deep penetration under 18 MPa, and gradient cooling enables ≥1.5mm fireproof layer depth and V-0 self-extinguishing performance—unachievable by standard presses—while negative-pressure detoxification ensures operational safety.

Component | Special Design for Flame-Retardant Equipment |

Heating System | Dual-circuit thermal oil + electric compensation, temp control ±2°C |

Steel Belt | AM350 stainless steel + ceramic coating, anti-oxidation |

Sealing System | Graphite-metal composite seals, resistant to 280°C creep |

Retardant Injector | High-precision dosing unit (±0.5% error) |

Exhaust Treatment | RTO incinerator (VOC removal >99%) |

Hydraulic System | High-temp ester-based fluid (flash point >320°C) |

Ⅴ. Differences vs. Standard Wood-Based Panel Equipment

Aspect | Flame-Retardant Equipment | Standard Equipment |

Process Goal | Form fireproof carbonized layer | Lignin plasticization & bonding |

Temp Control | Multi-zone precision gradient (±2°C) | Single-zone control (±5°C) |

Pressure Profile | High pressure + long dwell time (>120s) | Medium pressure + short dwell (60~90s) |

Material Compatibility | Corrosion-resistant alloys | Carbon steel components |

Safety Design | Explosion-proof motors + gas sensors | Basic protection |

Emission Control | Mandatory exhaust purification | Basic dust removal |

Our company development history

2007-2010

2007 -Our factory started to manufacture the full sets of OSB、PB、MDF Production line.

2013

Shandong Hungyou intelligent Equipment Industry ResearchCo..Ltd established, for plywood machinery and OSB、PB、MDF machinery research and development.The main research direction is to realize the automation of Plywood machinery.

2015

Linyi Ming Hung Trade Co.,Ltd established, the development focus has began to Foreignmarket, to service more foreign customers.

2017

Our High-end brand -ShandongMinghung OSB&MDF Machinery Equipment Manufacturing Co..Ltd established, mainly for foreign customers make the whole plant planning and design,achieve comprehensive high-end automation.

2018

Our High-end brand -Shandong MingHung Wood Machinery Co..Ltd established, mainly for foreign customers make the whole plant planning and design,achieve comprehensive high-end automation.

2022

Our factory's overseas business achieved significant growth,shipped machines to many different countriesl,ike America,Mexico,Columbia,Russia,Indonesia,Vietnam,Malaysia,Thailand,Egypt, TurkishUkraine, Romania, Portugal, Africaand others.

2024

We continue to adhere to the strategy of going global,to become one World brand.

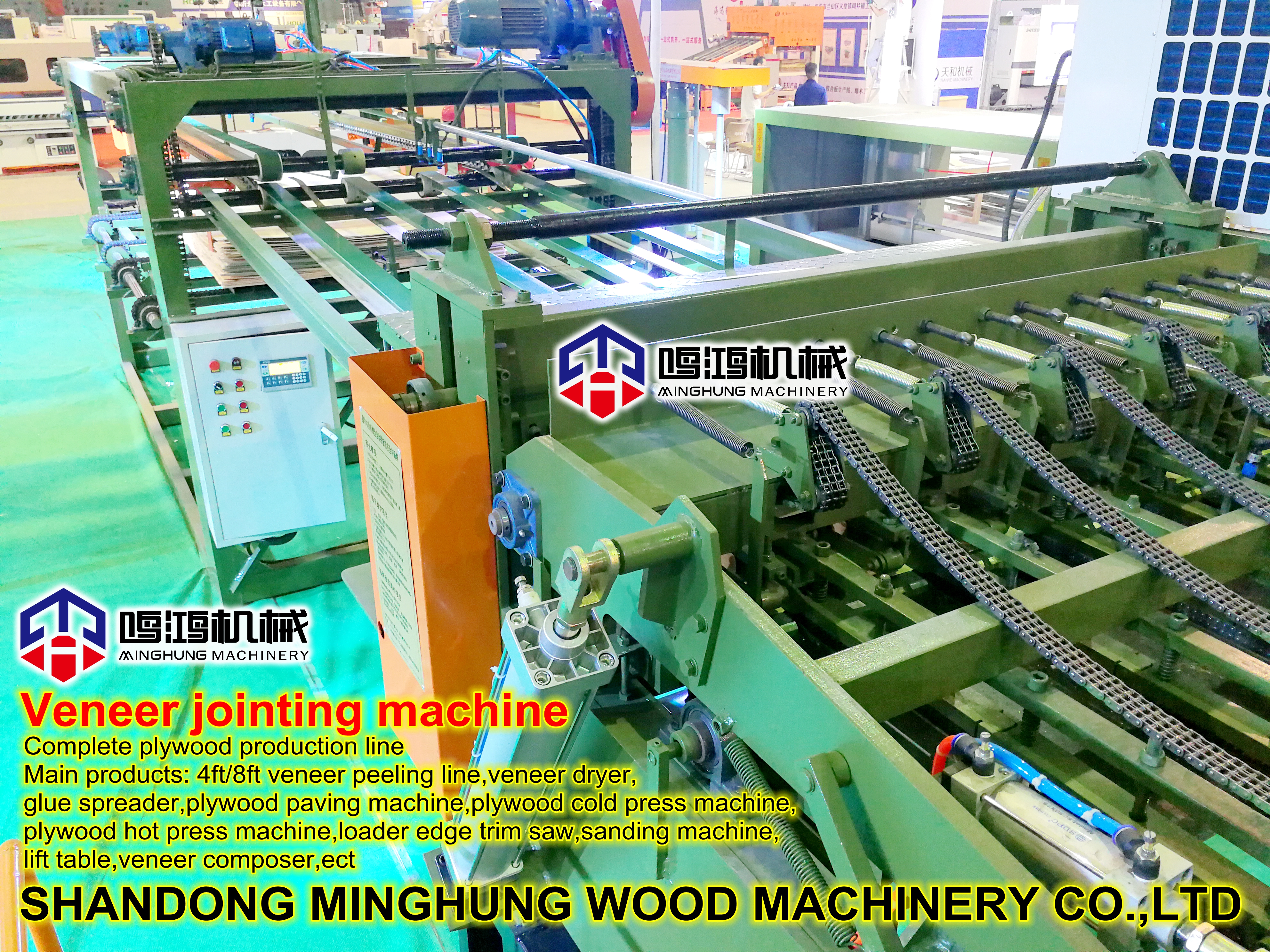

The machines we can offer includes: Wood chipper, Ring flaker, Strander, Wet silo, Drum dryer, Dry silo, Glue dosing and applying system /Glue blender, Mat forming, Continuous Multi-rolls pre-press, Multi opening hot press and Continuous press, Auto edge cutting machine line, Sanding machine line, kinds of related belt conveyor and so on.

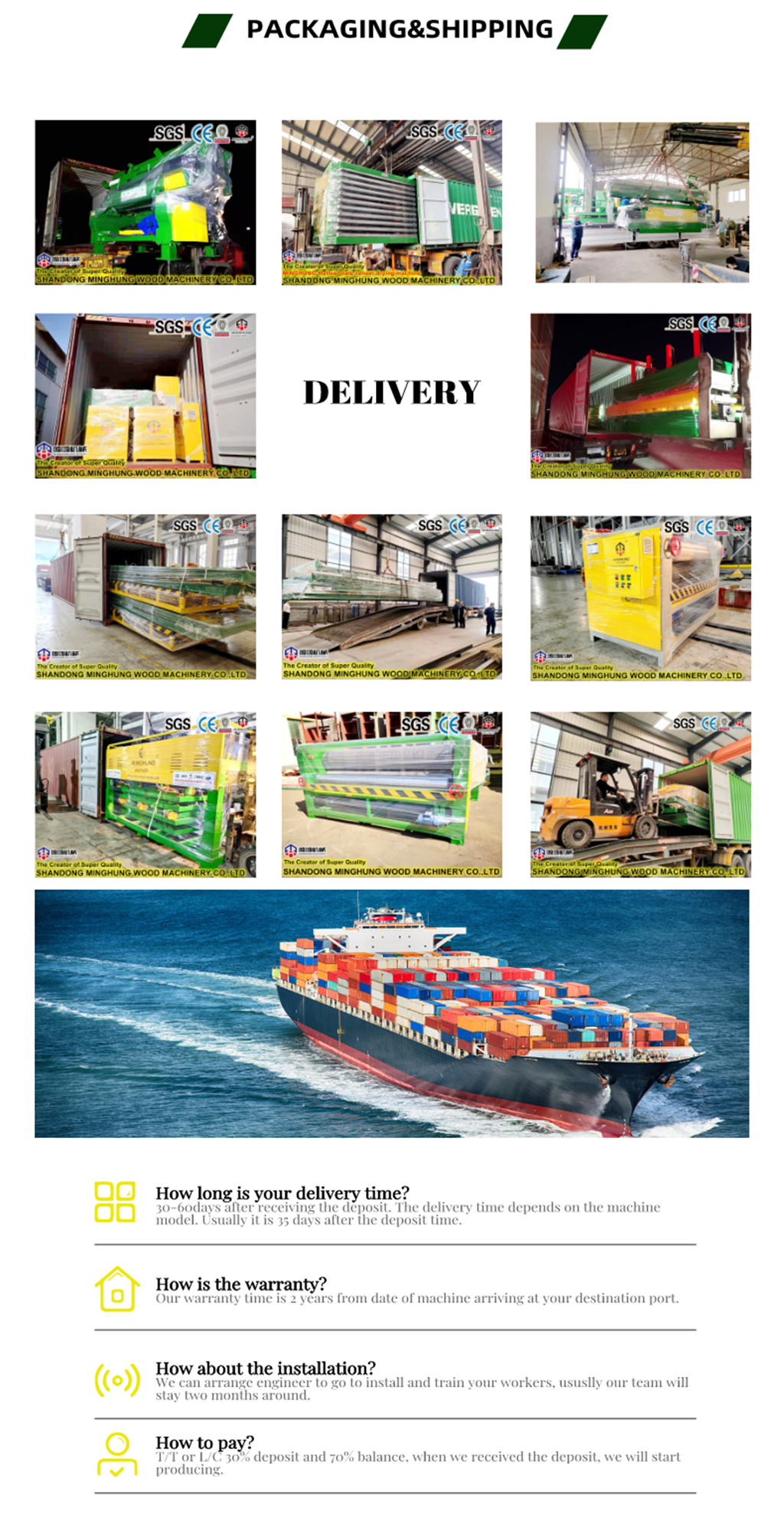

PACKING & SHIPPING

PACKING & SHIPPING