The Customization Process: From Concept to Reality

We offer a clear, collaborative process to ensure your needs are accurately understood and met:

1. In-Depth Needs Assessment: Our engineers will communicate with you to understand your raw material characteristics (wood species, avg. diameter/length), target product (veneer thickness, end-use), capacity requirements (daily/monthly output), and existing workshop conditions (space, power, connectivity to other equipment).

2. Solution Design & Quotation: Based on the assessment, we provide a detailed Customized Solution Configuration Sheet, clearly listing all optional modules, specifications, and corresponding prices. You can select and adjust based on your budget and priorities.

3. Technical Confirmation & Contract: Both parties confirm the technical details, performance metrics, delivery timeline, and after-sales service terms of the final configuration and sign the contract.

4. Modular Production & Testing: During manufacturing, key modules are produced in parallel. After assembly, the machine undergoes factory testing using dummy logs or your samples. Test videos or data are provided to confirm performance meets agreement.

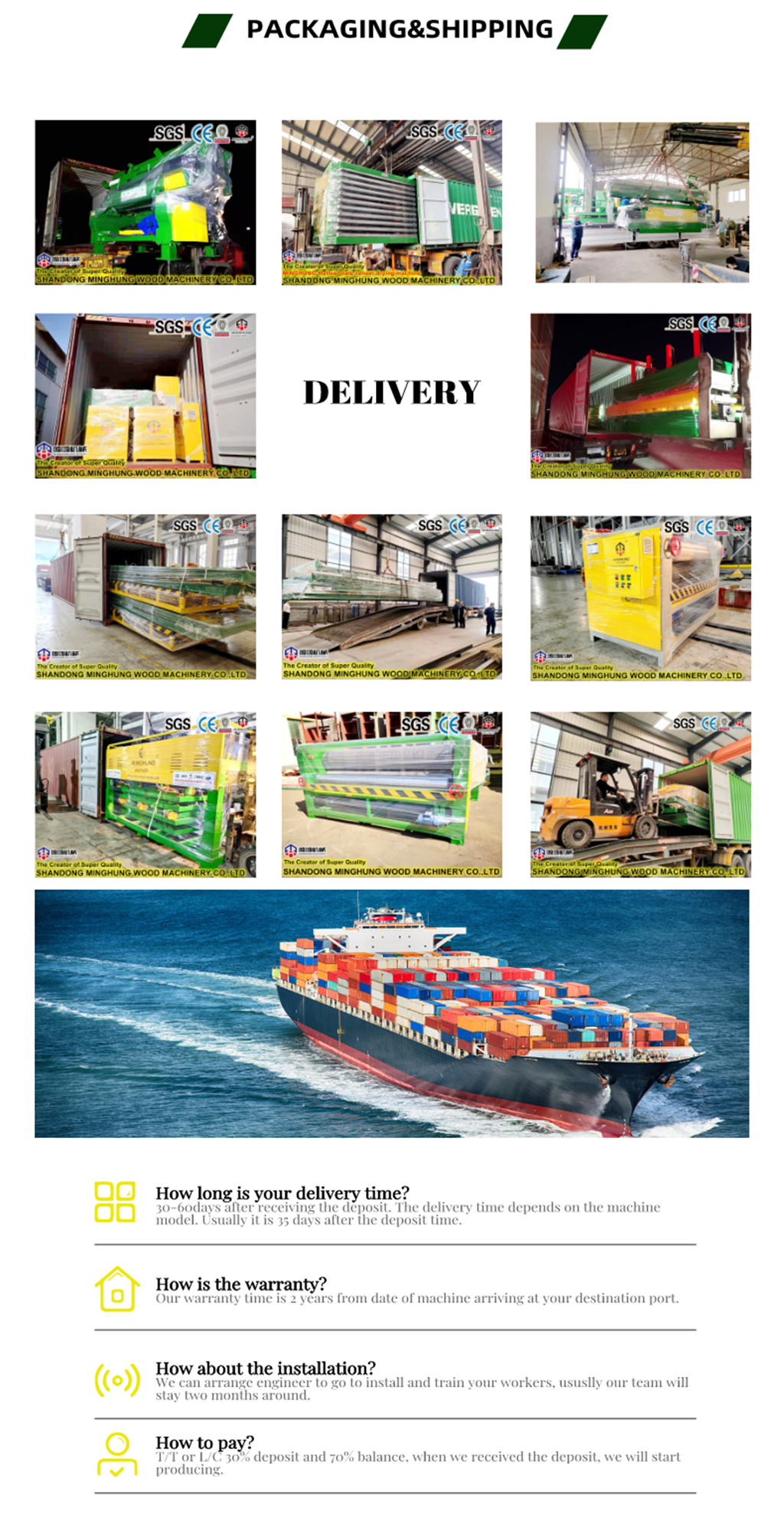

5. Delivery & Value-Added Services: We provide professional installation guidance, operator training, and customized maintenance manuals for the special features.