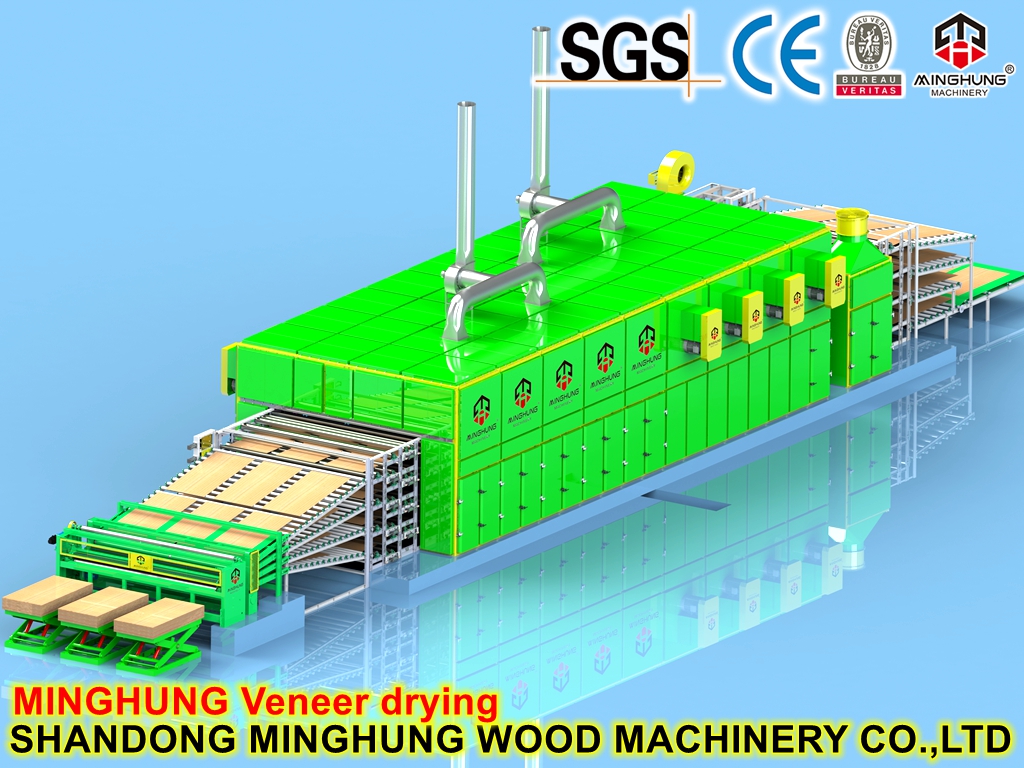

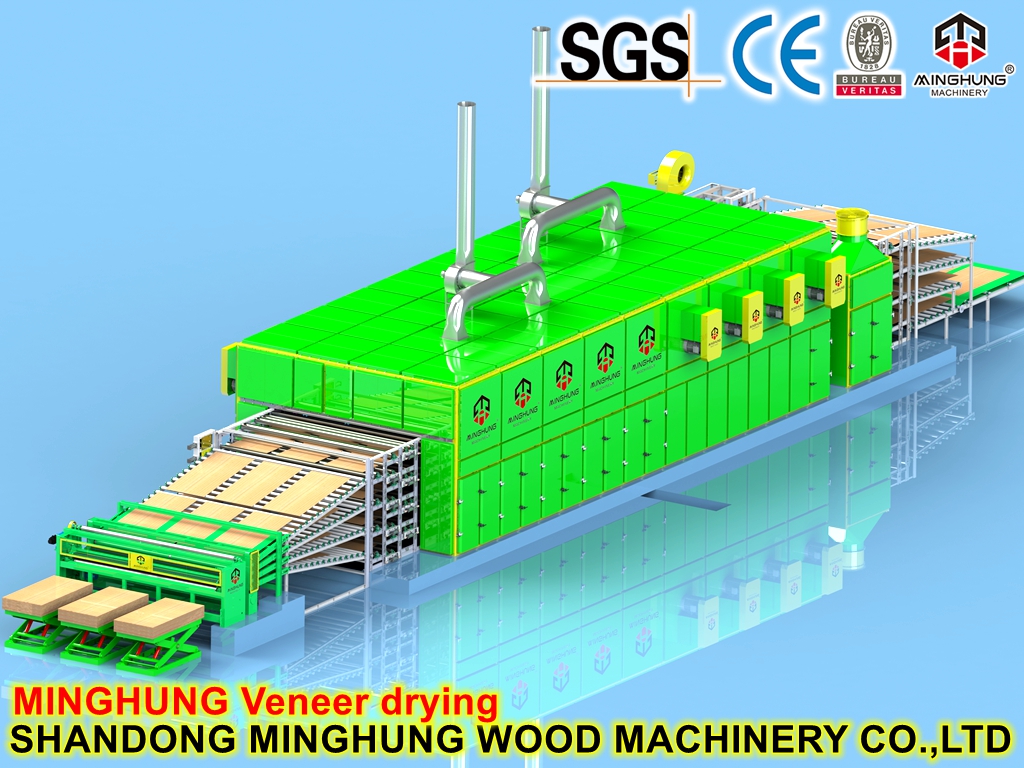

Veneer drying line

Veneer drying

Veneer roller dryer

Veneer wire dryer

4 decks veneer mesh dryer

4 decks veneer wire dryer

Veneer roller dryer

Veneer dryer machine

Drying wood veneer, remove abundant moisture, reach your requires.

Remove excessive moisture and prepares it for adhesive application and product fabrication

The purpose of drying is to reduce the moisture content of the stock to a predetermined percentage, and to produce flat and pliable veneer

Moisture content is one of the most important factors that can affect many physical and mechanical properties of wood and veneers. It strongly affects the final strength and durability of joints, development of surface checks in the wood and dimensional stability of the bonded assembly.

The hot air temperature is an important factor affecting the drying speed of the veneer for the veneer dryer. As the temperature increases, the evaporation rate of the surface of the veneer increases, and the speed of moisture movement inside the veneer also accelerates accordingly. Usually, the veneer dryer uses a high temperature of 100-200 ° C to dry the veneer to accelerate the evaporation of water. Under the action of high temperature, as the water inside the veneer evaporates, there is a large amount of water vapor inside the wood veneer roller dryer. The relative humidity of the circulating air is large. When the water vapor is saturated, the veneer can no longer evaporate water to the hot air. The vent hole should be opened to reduce the relative humidity of the air (the relative humidity of the air is too high to reduce the drying speed. If the relative humidity of the air is too small, the heat will be lost. Generally, the relative humidity of the air in the roller veneer dryer is 10-20%).

The veneer drying line, quite commonly is roller dryer, wire dryer, and press dryer. Different clients will choose different types according to their needs.

Today i am gonna introduce the roller dryer for you. For the veneer roller dryer, its convey way is through many rollers to convey veneers. According to the required drying capacity, veneers thickness and humidity and wood specis, the roller dryer can be different sections, width and floors. Today i am introduce the roller dryer with drying capacity 100m3 per day. which 4 floors, width 4000mm. Very big and high efficiency

| Name | veneer roller dryer |

| Drying capacity | 100m3/per day |

| Dryer width | 4000mm |

| Dryer floors | 4 |

| Sections | 12+2 (28m) |

| Motor | 170kw |

| Size | 40*7*4.3m |

| Weight | 100ton |