Air cylinder

1: What is a air cylinder

The cylinder is the executive element in the pneumatic system, which converts the pressure energy of the fluid into mechanical energy, outputs the force, and pushes the working mechanism to achieve a reciprocating straight line, or a reciprocating swing motion.

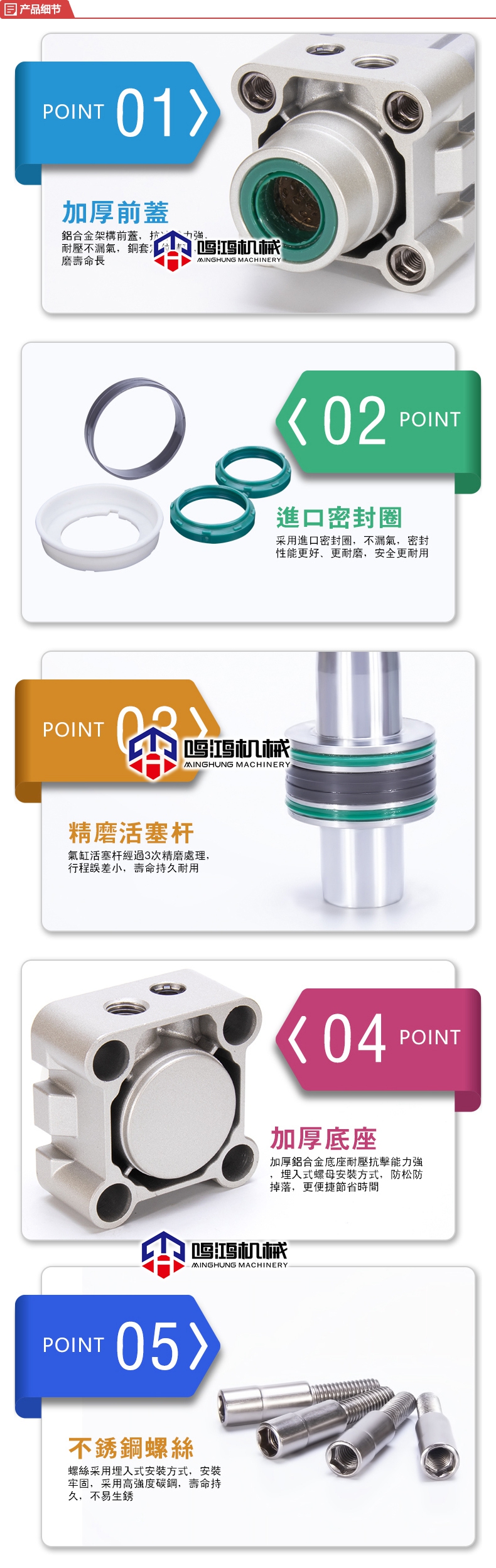

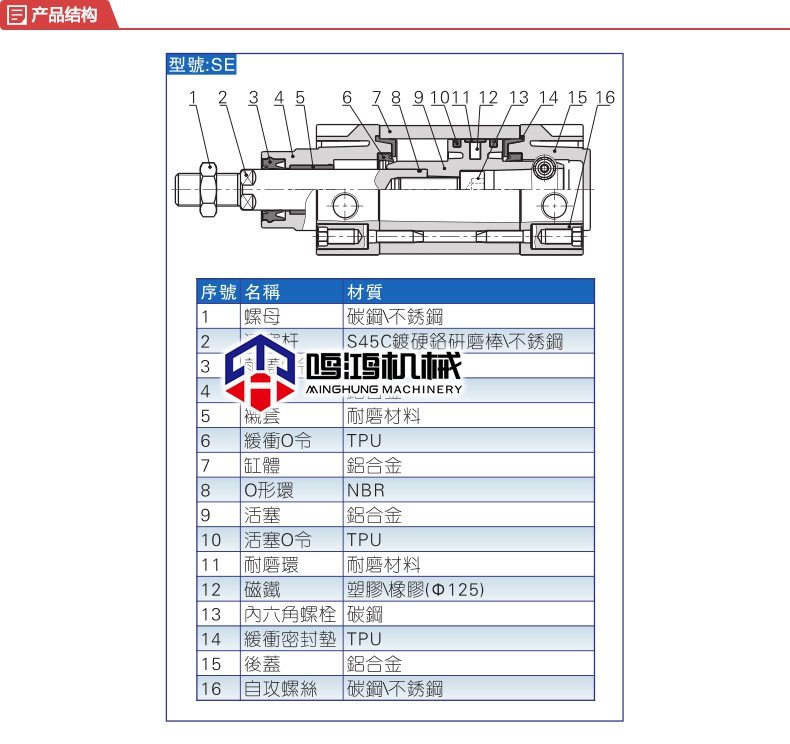

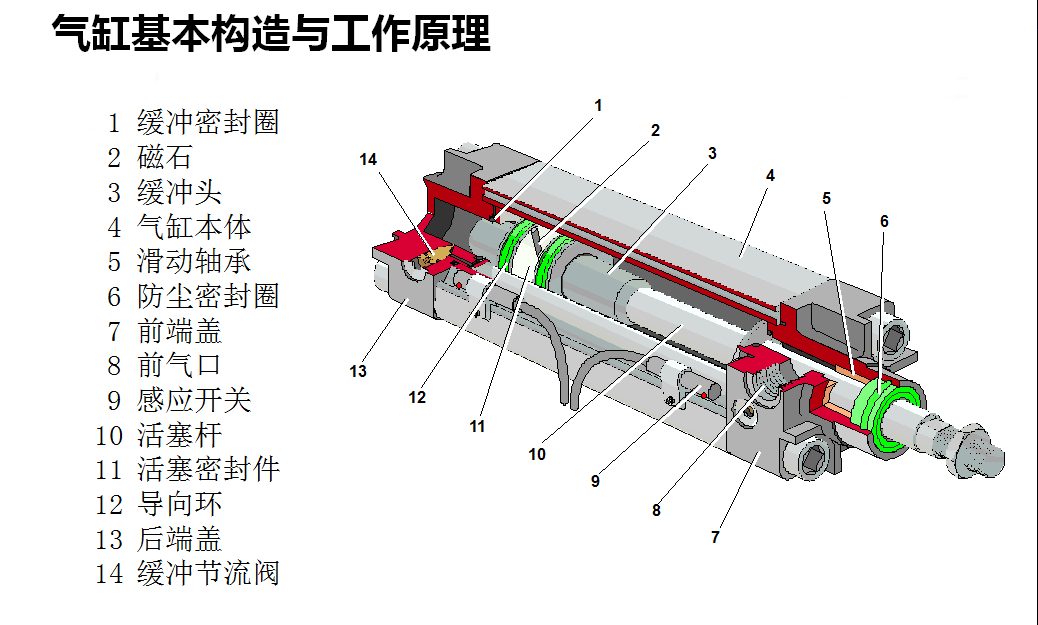

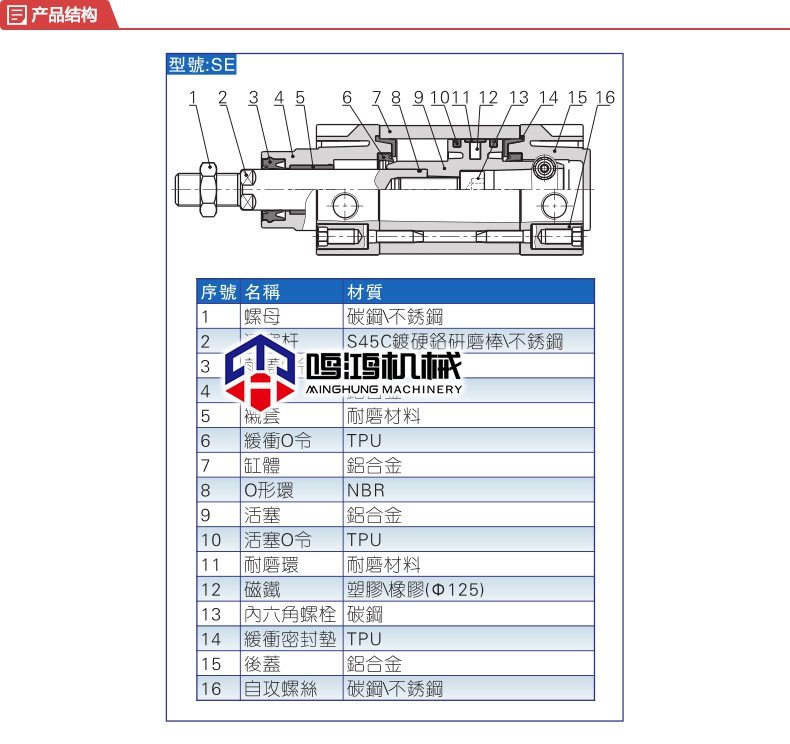

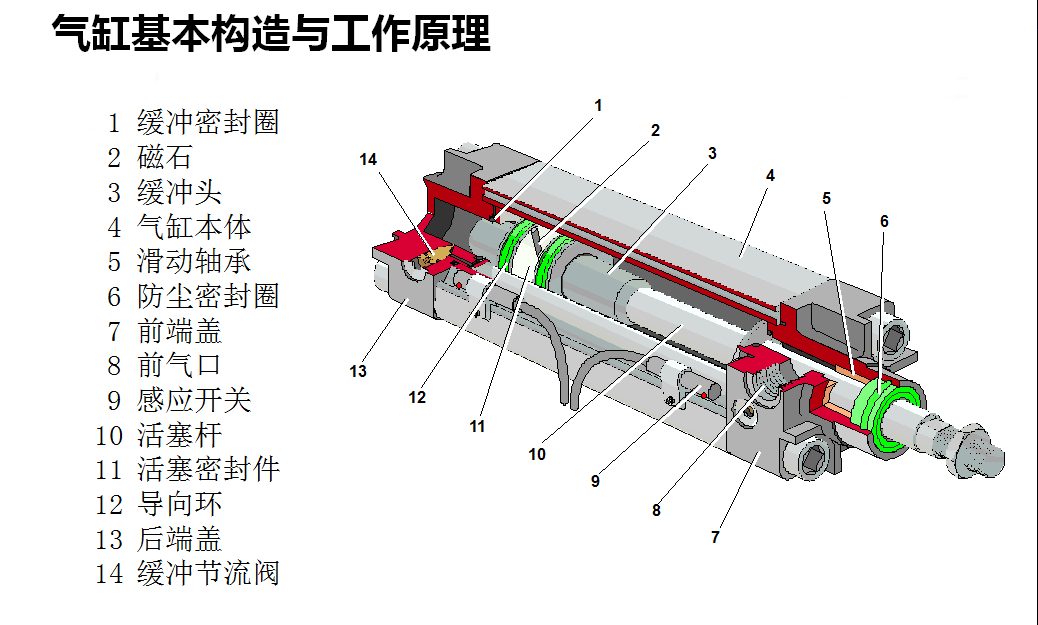

2: the structure of the cylinder

1. Use environment: The cylinder is used in situations where there is a danger of fire and explosion. Except for several special cylinders, its structure type is basically the same as that of the hydraulic cylinder.

2. Due to the high compressibility of the gas, the speed and position control accuracy of the cylinder is not high. At the same time, the pressure of the pneumatic system is low, and the output power of the cylinder is small.

3: the use environment and characteristics of the cylinder

4: Classification of cylinders

Cylinders can be divided into three categories, namely: single-acting cylinders, double-acting cylinders, and special cylinders. (For specific classification, see EXCEL form).

5: The calculation formula of the cylinder (here, taking the double-acting piston rod cylinder as an example, the thrust force F1 and the pulling force F2 on the piston rod are calculated according to the following formulas respectively.

F1=1/4×π×D∧2×p×η

F2=1/4×π×(D∧2-d∧2)×p×η

In the formula, F1——the output thrust of the double-acting single-piston rod cylinder (N)

F2——Output pulling force of double-acting single piston rod (N)

D——Piston diameter (m)

d——piston rod diameter (m)

p——Cylinder working pressure (pa)

η——load rate, which is related to the cylinder pressure, and comprehensively reflects the rapid movement of the piston and the efficiency of the cylinder. If the dynamic parameters of the cylinder are required to be high and the working frequency is high, the load rate generally takes the value (0, 3~0, 5), the smaller value is taken when the speed is high, and the larger value is taken when the speed is low; If the dynamic parameters of the cylinder are generally required and the working frequency is low, it is basically a uniform motion, and only the total resistance can be considered, and the load rate can be taken as (0, 7~0, 85).

6. Calculation example of cylinder selection

For example: use the cylinder to push the trolley horizontally, the load mass of the trolley is M=150KG, the friction coefficient between the trolley and the contact surface is μ=0, 3, the cylinder stroke L=300mm, the action time of the cylinder is required t=0, 8s, the working pressure For P=0, 5Mpa, please select the cylinder bore size!

Problem solving:

1, the axial load force of the cylinder F=μMg=0, 3*150*9, 8=450N

2, the average speed of the cylinder

v=stroke/action time of cylinder=L/t=300/0, 8=375mm/s, according to the value of dynamic load in the table above, load rate η=0, 5

3. From this, the theoretical output force of the cylinder is derived