China OSB Production Line

| The Introduction of OSB board |

Oriented Strand Board (OSB) is an engineered wood product made from oriented wood chips (shavings) pressed with a resin binder under high temperature and pressure. It has high strength, durability and cost effectiveness, and is widely used in construction and furniture manufacturing. Because its good features such as high strength, moistureproof, environmental protection, economical, so it is widely used in furniture production, construction structure, decorations, and packings

| OSB Production Machines |

- Raw materials preparation

wood strands /flakes

wood strands /flakes

Wood peeling machine

By wood peeling machine to processing the wood, to make wood strands /flakes; or by the disc chipper, as different raw materials wood

For wood strands, the typical length is 50mm-150mm; common length is 75-125mm. The typical width is 10-25mm, the common width is 15-20mm. The typical thickness is 0.5-1mm, common thickness is 0.6-0.8mm

- Round screening

Round sieve

Round screener

Screening machines in Oriented strand board (OSB) production are mainly used to separate wood chips and ensure uniform size. It works as follows:

1. Feed system

- Function : evenly feed the wood chips into the screening machine.

- Composition: Usually includes conveyor belt or vibrating feeder.

2. Screen System

- Function: Separate wood chips through screens of different apertures.

- Composition : multi-layer screen, each layer aperture is different, the upper aperture is large, the lower aperture is small.

3. Vibration system

- Function: Make the wood pieces move on the screen to promote separation.

- Composition: Vibration device driven by motor to ensure uniform distribution of wood chips.

4. Layered Collection system

- ** Function ** : Collect wood chips of different sizes.

- ** Composition ** : There is an independent collection trough or conveyor belt under each layer of screen.

5. Discharge system

- Function: Transfer the screened wood chips to the next process.

- Composition: Conveyor belt or pipe, connected to drying or sizing equipment.

- Drying

Drum dryer

Rotary dryer

The aim of Dryer is to reduce the moisture content of the wood chips /wood strands to an appropriate level (usually 2%-5%) to ensure the quality of subsequent gluing and hot pressing.

The purpose of drying:

- Reduce moisture content: Make the moisture content of wood pieces uniform, avoid poor bonding or sheet deformation.

- Improve the bonding effect: The appropriate moisture content helps the adhesive to penetrate and cure evenly.

- Prevent mildew: Reducing water content reduces the risk of mildew in storage and transportation.

Dryer types:

- Tumble dryers: Common equipment where wood chips come into contact with hot air in a rotating drum.

- Air dryer: Use high speed hot air flow to dry wood chips, suitable for mass production.

- Multi-layer dryer: Wood chips are passed through hot air on a multi-layer conveyor belt, suitable for continuous production.

- Gluing system

Glue mixing

Glue apply system

- Mixed Adhesive: The shavings are mixed with a resin adhesive (usually phenolic resin or isocyanate) to ensure that the surface of the shavings is evenly covered.

- Additives: add water repellent, fire retardant, etc., as needed.

- Directional Forming

Mat forming

Forming machine

- Forming: The shavings after sizing are arranged in a specific direction, usually the surface shavings are arranged along the board length direction, and the core layer shavings are arranged perpendicular to the surface layer.

- Laying machine: Use the laying machine to evenly lay the shavings on the forming belt.

- Continuous Pre-press

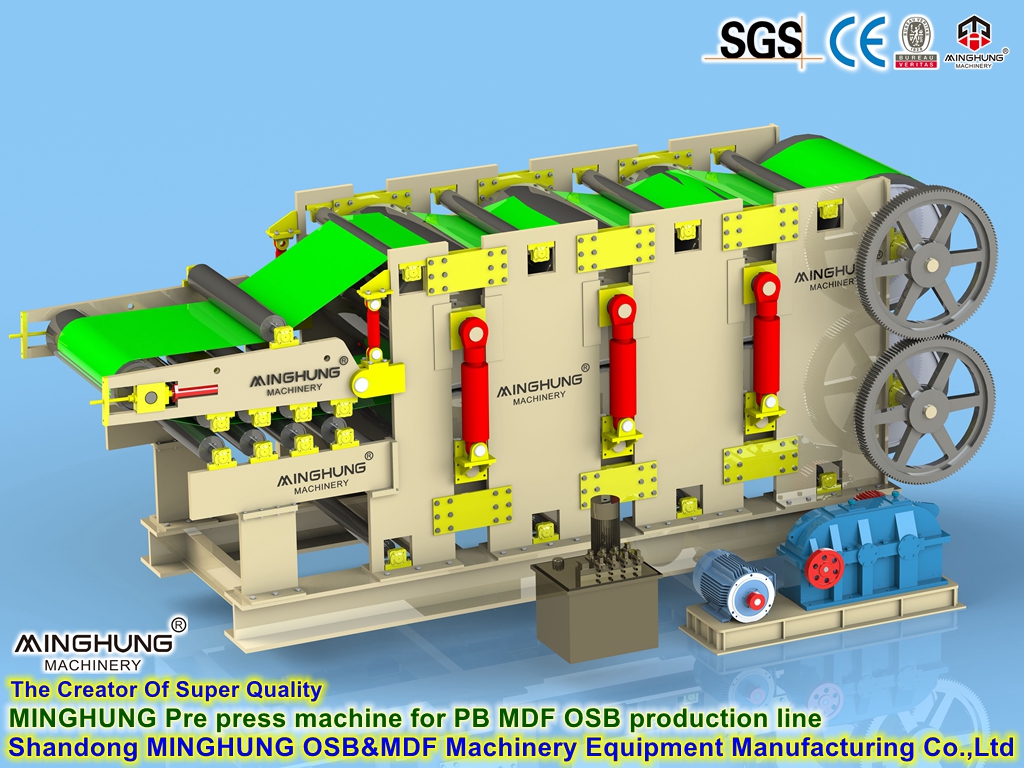

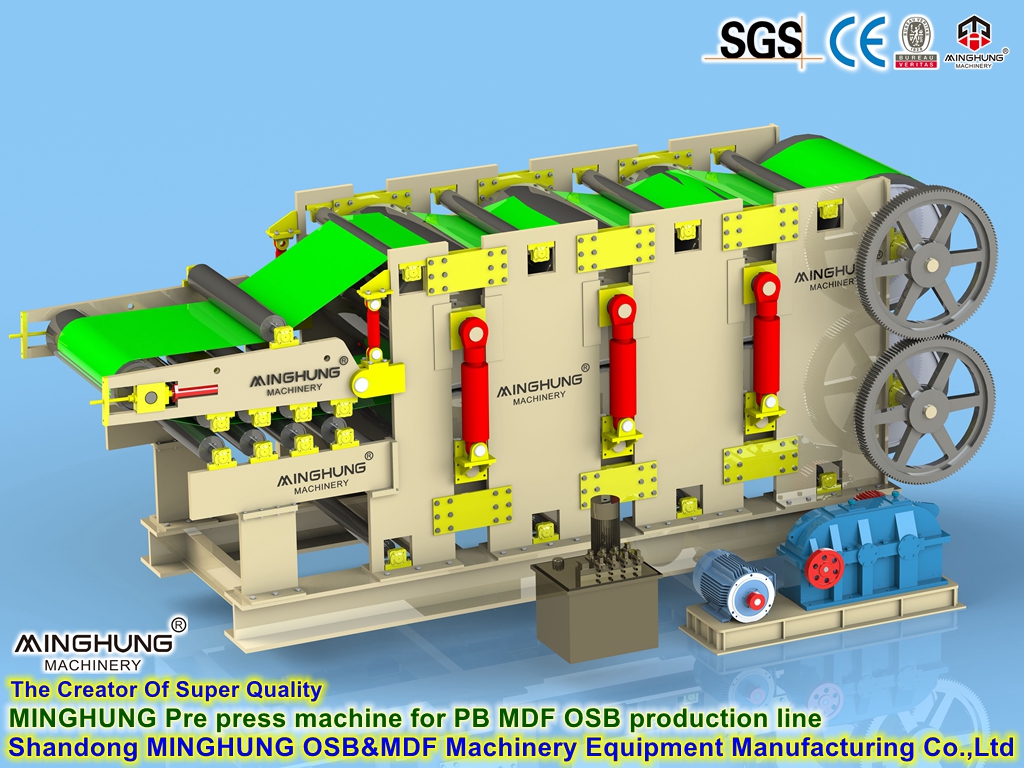

MINGHUNG Designed 3D drawing

Continuous Pre-press for OSB production

- The formed shavings are initially compacted by the prepressing machine to reduce thickness and increase density.

- Multi-layers Hot press

Multi-layers hot press

Hot press with auto loader and unloader

- Hot pressing: The prepressed slab is sent to the hot press and pressed under high temperature (180-200°C) and high pressure (2-5 MPa) to solidify the adhesive and bind the shavings tightly.

- Cooling: The sheet after hot pressing is cooled by the cooling system to stabilize the size.

- Cutting and Sanding

Edge cutting machine

Sanding machine

- Edging: Cut the sheet to standard size and remove the raw edge.

- Sanding: Sanding the surface of the plate to make it smooth and smooth.

- Quality test and Packing

After test the quality of OSB is good, then you can packing it and loading

As China professional factory and supplier of these wood based panel machinery, we can offer you the suitable and good machine

Welcome contact us