500t Pre Pressing Plywood Cold Press

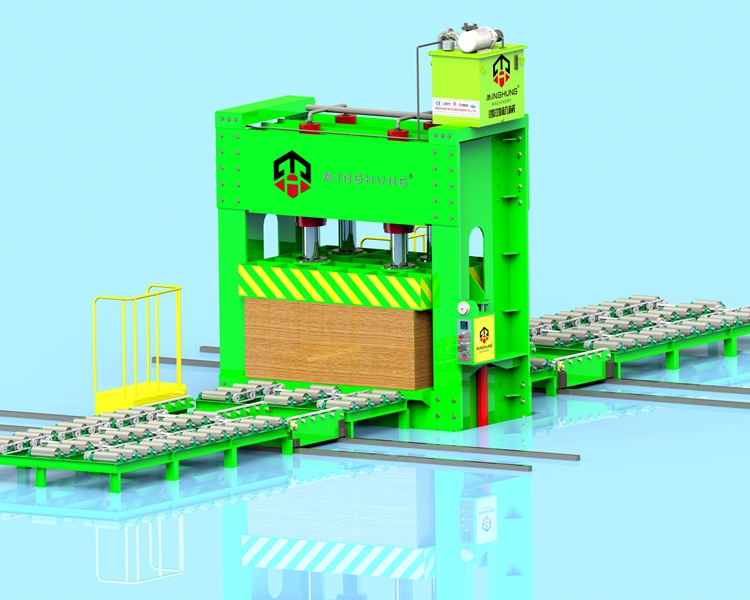

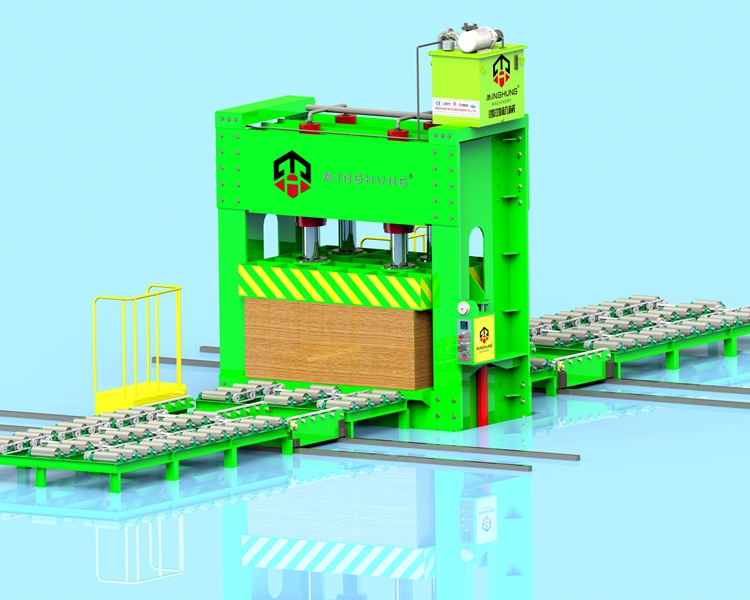

The cold press is a new type of equipment developed by SHANDONG MINGHUNG WOOD MACHINERY.

It is used for pressing wooden doors, furniture panels, various panels and furniture, and the shaping processing cold press can make the panels stronger. Cold press preferred MINGHUNG cold press

1. This machine is suitable for decorative boards, plywood, block boards, building formwork laminated boards, floors, and pre-pressing processes in the same direction as board factories;

2. The overall structure design adopts international advanced technology, combined with new process requirements, carefully designed and manufactured;

3. The hydraulic system and circuit have been precisely tested, and the movable beam has no self-falling phenomenon, ensuring excellent quality;

4. The hydraulic cylinder is made of special superhard material, the hardness of the plunger is above HRC55, and the seal adopts a low negative pressure step ring, no oil leakage, long service life and low maintenance cost;

5. The optional feeding and discharging mechanism adopts chain transmission, which will not damage the slab.

The woodworking cold press series models are used to press furniture panels, wooden doors, various panels, and furniture leveling and shaping. It can make the bonding between the panels stronger. The pressure is strong and there is no pull back. The working form of woodworking cold press can be roughly divided into: screw type and hydraulic type.

Whatsapp: +8618769900191 +8615589105786 +8615805493072

Email: minghungmachinery@gmail.com

Website: www.plywoodmachineline.com

>>>Specification:

| Pressure | 400t /500t /600t |

| Cylinder diameter | Φ320*2pcs /Φ360*2pcs /Φ260*6pcs |

| Power | 18.5kw |

| Application | For pressing plywood, melamine plywood, furniture plywood... |

| Max opening | 1800mm |

| Size | 3600*1370*4000mm |

>>>Main Parts:

Cylinder:

The oil cylinder is treated with anti-rust, alloy casting, high hardness, scratch resistance, suitable for high-strength operations, and uses a good oil seal to prevent leakage, ensure the pressure in the oil cylinder, and good performance

Hydraulic Station:

Hydraulic station is one important part for press machine, Our hydraulic station be designed by our engineer, reasonable design of hydraulic system, save energy, all hydraulic components are arranged reasonably, neatly and beautifully placed, and the components like electromagnetic valve, hydraulic pump all use good one.

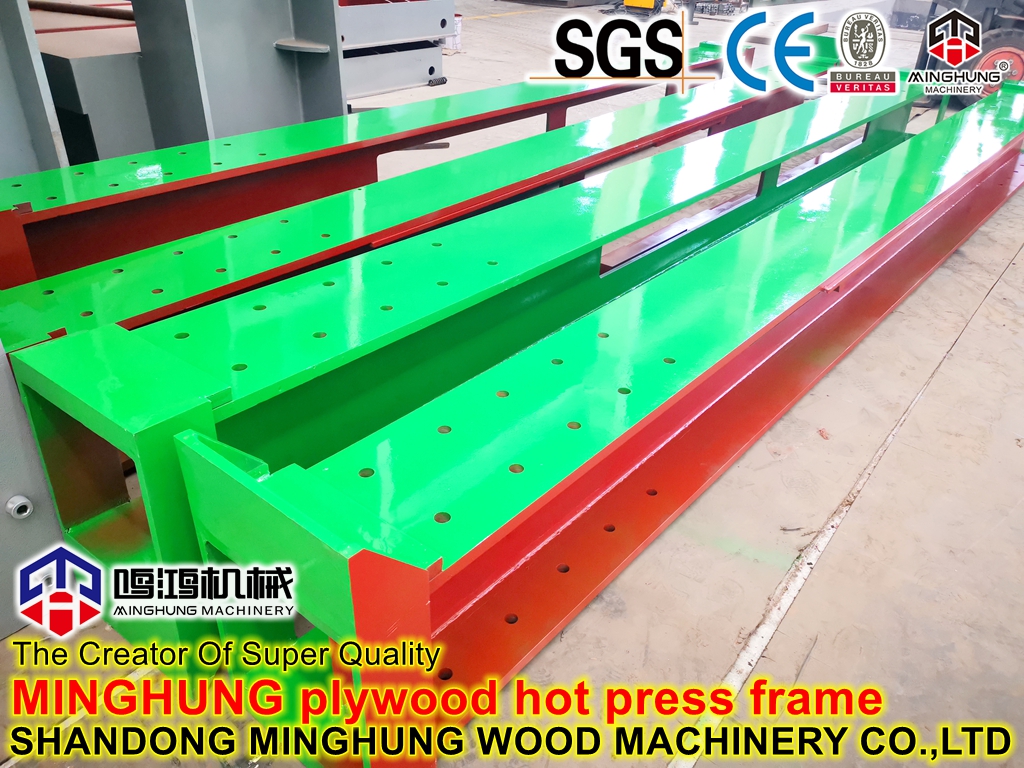

Frame of Cold Press:

Using International standard steel plate, big rigidity and high strength.

>>>Our factory:

Our main products include wood log debarker, veneer peeling machine, vacuum veneer stacker, veneer dryer machine, plywood cold press machine, plywood hot press machine, glue spreader, glue mixing machine, automatic plywood veneer paving line, plywood saw machine, sanding machine.

Scientific and technological innovation oriented, quality-based, service supremacy, we offer full complete range of plywood production solution and technology support for our customers. Yet our machines have been exported more than 30 countries and regions like Russia, Poland, Ukraine, Portugal, Bulgaria, Romania, Turkey, Egypt, Morocco, Indonesia, etc, and get good feedback.

With high efficiency sales team offer 24 hours online service, the professional technical team and after-sales service team offer plant layout, machine drawings, and after-sales service.

Choose us, you need not worry anything, we will help you arrange all.

>>>Delivery:

1> When loading, we will share the loading pictures of plywood press machine with you.

2> When ship leave, we will offer the container and ship information for you.

3> Offer all documents which for your custom clearance.

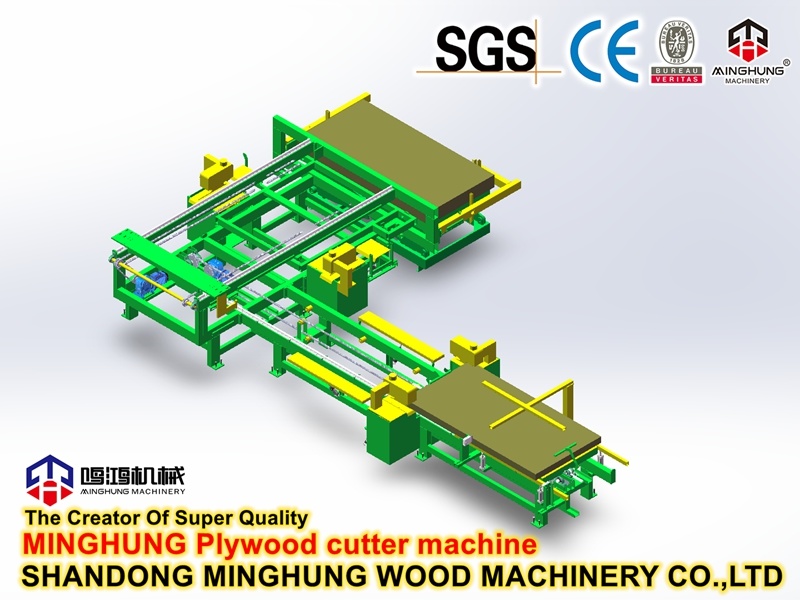

>>>Related Plywood Machine:

For making plywood and lvl board, these machines glue spreader, hot press, plywood edge cutting machine also be required

>>>RFQ:

| Production Time: |

| 1 month after receive your deposit. |

| Payment Terms: |

30% deposit, 70% before delivery.

100% Letter of Credit. |

| Warranty: |

| 2 years for main parts. |

| MOQ: |

| 1 set |

| Installation: |

| When machine reach your factory, our engineer can go to install |

| After-sales service: |

| Any problem that your worker can not solve, tell us, we will reply you at the first time, |

Contact us:

Whatsapp: +8618769900191 +8615589105786 +8615805493072

Email: minghungmachinery@gmail.com

Website: www.plywoodmachineline.com