Plywood Machine Plywood Production Line Plywood Making Machine Full Sets

Multi-layer plywood production process

Multi-layer plywood production process

1. The main equipment required for the production of plywood:

1. 2700mm, the whole line of rotary cutting machine.

2. The whole line of 1500mm rotary cutting machine.

3. A knife sharpener.

4. One veneer dryer, customized according to the output of plywood.

5. 1 glue mixer

6. Glue coating machine 1 set 2700mm

7. cold press machine 1set

8. hot press machine 1set

9. Plywood edge sawing machine 1set

2. Production process of multi-layer plywood nine-layer plywood:

Poplar→broken wood→veneer peeling→veneer drying→finishing and repairing veneer→glue mixer mixing ratio→glue spreader gluing and stringing→group embryo board→pre-pressing machine pre-pressing→hot pressing machine hot pressing→plywood saw Edge → plywood inspection → secondary coating → hot pressing → secondary inspection → storage

The specific process flow is as follows:

1. Poplar, beech, birch, eucalyptus, and other woods are classified according to their length and diameter, and then cut into segments with a chainsaw.

2. Use different rotary cutting machines to cut veneer with different thicknesses such as 2.2mm, 1.7mm, 1.5mm, etc.

3. The single veneer is neatly stacked on the tray and transported to the dryer for veneer drying. The temperature in the dryer reaches 120-150 degrees Celsius, and the moisture content of the veneer after drying is less than 10%, and it works continuously.

4. After the dried veneers are stored and stacked, they are sorted, repaired and sorted.

5. Put the different classified veneers into the gluing machine for gluing.

6. Arrange the glued veneers in a criss-cross pattern of plywood embryos (5 layers, 7 layers, 9 layers, 12 layers), and the thickness is assembled and arranged according to the thickness of the plywood. The thickness of the plywood is as follows:3mm, 6mm, 9mm, 12mm, 15mm, 18mm, 25mm, 28mm, etc.,

7. The semi-finished plywood after grouping is pre-pressed, and the pre-pressed plywood is easy to be hot-pressed and not easy to dislocate.

8. Put the pre-pressed semi-finished plywood into the hot press for high temperature hot pressing. The temperature of the hot pressing plate of the hot press is 120-130 degrees Celsius, and the pressure is adjusted according to the pressure of the hot press.

9. Saw edge processing according to the size of the finished heat press

10. The quality inspection is carried out according to the samples of the sawn plywood products. The inspection content usually includes the plywood front degree, the plywood water resistance test, the plywood surface is required to be smooth and flat, the thickness is uniform, and the four sides are straight at a 90-degree angle, etc.

For more information on plywood contact us:

Our factory produce the whole sets Plywood Machine, include plywood hot press machine, plywood cold press machine, glue spreader, plywood veneer paving line, plywood edge cutting saw, sanding machine and others. >>>>VENEER PEELING MACHINE:

Our factory produce the whole sets Plywood Machine, include plywood hot press machine, plywood cold press machine, glue spreader, plywood veneer paving line, plywood edge cutting saw, sanding machine and others. >>>>VENEER PEELING MACHINE:

Veneer production line includes: Wood debarker, Wood peeling machine, Log conveyor, Vacuum veneer stacker.

Thie full peeling line will produce wood veneer through processing wood log.

The standard size includes 4feet and 8feet, which can peeling max log length 1400mm and 2600mm, But we also can customize veneer machine according to your needs, for example, some our customers require 1800mm veneer machine, some require 2000mm machine, we can produce.

With advanced production technology, and professional and experienced workers, we can promise you that our peeling machine very good and strong to help you produce good quality wood veneer.

>>>> Veneer Drying Line

Veneer dryer includes Roller dryer, Mesh/Wire dryer, and Press dryer.

Each type veneer dryer has its own advantages and characters, we will offer the suitable dryer according to your needs.

Roller dryer and Wire dryer can be different floors and length according to the drying capacity, therefore if you want to big drying capacity and continuous drying, these two are good choice.

Some our clients will require dryiing 70m3/per day, some require 100m3/per day.

For press dryer, it cover few workshop room, and price more favorable compare above two dryer types, of course its drying capacity smaller, so you can buy several sets according to the drying capacity. >>>>HOT PRESS MACHINE:

| Product name | Plywood Hot Press Machine |

| Layers | 8 /10 /12 /15 /20 /25 |

| Pressure | 400t /500t /600t /800t /1000t /1200t |

| Cylinder | φ320*2pcs /φ360*2pcs /φ220*6pcs /φ260*6pcs |

| Hot platen size | 2700*1370*42/52/62mm |

| Power | 18.5kw/29.5kw |

| Weight | 33t /48t |

Advantages:

<1> hot press machine frame use thick steel plate, all welding place be grinding finely, make sure machine good quality and beautiful.

<2> The hot platen be processed by large lathe, make the surface is smooth, with sufficient strength and stiffness. Under the high temperature, it will not change its shape, and transfer hear uniformly. This makes the plywood heated evenly, and surface is flat, help you produce good quality plywood.

<3> The oil cylinder is treated with anti-rust, alloy casting, high hardness, scratch resistance, suitable for high-strength operations, and uses a good oil seal to prevent leakage, ensure the pressure in the oil cylinder, and good performance

<4> Hydraulic station is one important part for press machine, Our hydraulic station be designed by our engineer, reasonable design of hydraulic system, save energy, all hydraulic components are arranged reasonably, neatly and beautifully placed, and the components like electromagnetic valve, hydraulic pump all use good one. >>>>COLD PRESS MACHINE:

| Product name | Plywood Cold Press Machine |

| Pressure | 400t /500t /600t |

| Cylinder | φ320*2pcs /φ360*2pcs /φ220*6pcs |

| Power | 18.5kw |

| Weight | 10t /12t |

| Size | 3600*1370*4000mm |

Advantages:

<1> the structure of cold press machine is simple, and easy operate for worker.

<2> the frame of cold press machine uses thick and good one, make sure hydraulic cold press is stable.

<3> The oil cylinder is treated with anti-rust, alloy casting, high hardness, scratch resistance, suitable for high-strength operations, and uses a good oil seal to prevent leakage, ensure the pressure in the oil cylinder, and good performance

<4> Hydraulic station is one important part for press machine, Our hydraulic station be designed by our engineer, reasonable design of hydraulic system, save energy, all hydraulic components are arranged reasonably, neatly and beautifully placed, and the components like electromagnetic valve, hydraulic pump all use good one. >>>>GLUE SPREADER MACHINE:

| Product name | glue spreader |

| Sides | Double sides at the same time |

| Size | 4feet/8feet or customize |

| Diameter of coating roller | φ310 /φ410 |

| Line speed | 20-30m/min |

| Installed capacity | 5.5kw |

| Transmission way | gear &chain transmission |

| Size | 2250*1250*1700mm

3250*1250*1700mm |

Advantages:

<1> Glue spreader's structure is simple, easy operate.

<2> Transmission by gear & chain, fast speed, high efficiency.

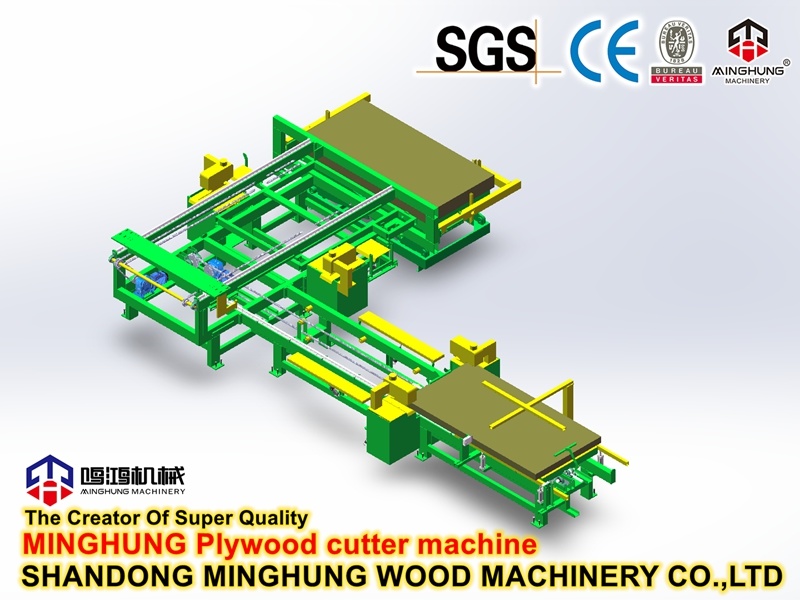

<3> Using good and big diameter roller, good quality >>>>PLYWOOD SAW MACHINE:

| Product name | plywood edge cutting saw |

| size | 4*8feet /3*6feet /customize |

| working speed | 40-70m/min |

| capacity | 8-12pcs/min |

| working style | infrared ray guide |

| feeding way | automatic |

| with one set lift table |

Advantages:

Be controlled by micro-computer, easy operate.

<2> Be positioning by infrared ray, accurate

<3> Be controlled by PLC, automatic cutting. >>>> Sanding Machine  for sanding machine, it includes many different types.

for sanding machine, it includes many different types.

For example, sanding machine can be single side, can be double sides; It can be one head, two heads, three heads

And they will have different function and sanding capacity.

Some sanding machine mainly for calibrating plywood thickness, some sander mainly for polishing plywood surface. >>>>ABOUT US:

We-Shandong MINGHUNG Wood Machinery is one of the leaders of plywood machine in China, supplies a complete range of machinery, systems and technology for the production of plywood and veneer including wood debarker, veneer peeling machine, vacuum veneer stacker, knife grinder, veneer dryer machine, glue spreader, cold press, hot press machine, plywood saw machine, sanding machine.

We-Shandong MINGHUNG Wood Machinery is one of the leaders of plywood machine in China, supplies a complete range of machinery, systems and technology for the production of plywood and veneer including wood debarker, veneer peeling machine, vacuum veneer stacker, knife grinder, veneer dryer machine, glue spreader, cold press, hot press machine, plywood saw machine, sanding machine.

Highly qualified personnel and competent management take all the advantages of production and continue developing day by day, the basis of our business is focus on our clients' needs, such position allows us to build long-term partnership with our clients in China and abroad.

We also works closely with a global network of manufacturing partners in order of provide the reliable, good quality and service to our customers. >>>>CLIENTS:

>>>>DELIVERY:

>>>>DELIVERY:

Welcome contact us for more information.

Welcome contact us for more information.

You will be surprised and happy to know us,

Best regards

Lucinda /Sales Manager

SHANDONG MINGHUNG WOOD MACHINERY CO.,LTD