Key Features and Design Considerations

1. High Pressure Capacity:

OSB uses larger strands and requires high strength, often in thick sections.

The press must provide very high maximum working pressure (typically above 500-1000 tons per meter of width) to effectively compress the thick, loose mat composed of large strands.

The pressure system (usually an array of hydraulic cylinders) needs precise pressure distribution control.

2. Large Opening Height and Long Press Platen:

Large Opening: Accommodates the typically thick OSB mat (finished thickness can reach 40mm or more), requiring sufficient opening height for mat entry.

Long Platen: OSB uses adhesives (typically Phenol-Formaldehyde resin - PF) that cure at higher temperatures, necessitating longer press times. The length of the continuous press (typically 30 to 50+ meters) provides sufficient press time to ensure full core resin curing. A longer press also allows finer control of process parameters in different press zones.

3. Precise Temperature Zone Control:

The press platen is divided into multiple independent heating zones (often 20+).

Each zone can be controlled independently (typically 180°C - 220°C or higher, depending on resin).

This zonal control optimizes the heating curve: higher temperatures might be needed at the entry for fast surface curing, maintained in the middle for core curing, and potentially reduced near the exit to minimize pre-cured layers or control moisture gradients. This is crucial for ensuring OSB's physical-mechanical properties (especially internal bond strength) and preventing delamination.

4. Precise Thickness Control & Density Profile:

Position Control System: The press has numerous position sensors and cylinders along its length, forming a closed-loop control system.

Continuous Thickness Measurement: Devices like laser scanners typically monitor panel thickness in real-time at the exit.

The system dynamically adjusts cylinder pressure and position based on set thickness and real-time measurements, ensuring highly uniform thickness across the entire panel.

Controlling the pressing curve (pressure vs. position over time/length) in different zones optimizes the panel's density profile distribution (higher surface density, relatively lower core density), vital for balancing OSB strength and dimensional stability.

5. Adaptation to Large Strands and Oriented Mat:

Design must account for the different sizes and orientations of strands in OSB surface and core layers.

Pressure gradients at the entry must avoid disrupting the oriented surface structure while effectively compressing the thicker core layer.

6. High-Strength, Wear-Resistant Steel Belt System:

Top and bottom high-strength, heat-resistant, wear-resistant steel belts are the core components.

OSB production places extreme demands on belts due to severe abrasion from large strands and high pressure.

Belts require precise tensioning and tracking systems for smooth operation, preventing misalignment or wrinkling.

7. Efficient Mat Handling:

The continuous press must integrate seamlessly with high-speed, precise mat formers (typically continuous forming) and mat conveying systems.

A pre-press is critical for preliminary compaction of the loose OSB mat, reducing thickness variation entering the main press.

8. Advanced Automation & Process Control:

Integrated, highly automated control systems (PLC/DCS) monitor and control thousands of parameters (pressure, temperature, position, speed, thickness) in real-time.

Synchronization with upstream (blending, forming) and downstream (cooling, trimming) equipment.

Capabilities for data acquisition, storage, analysis, and process optimization.

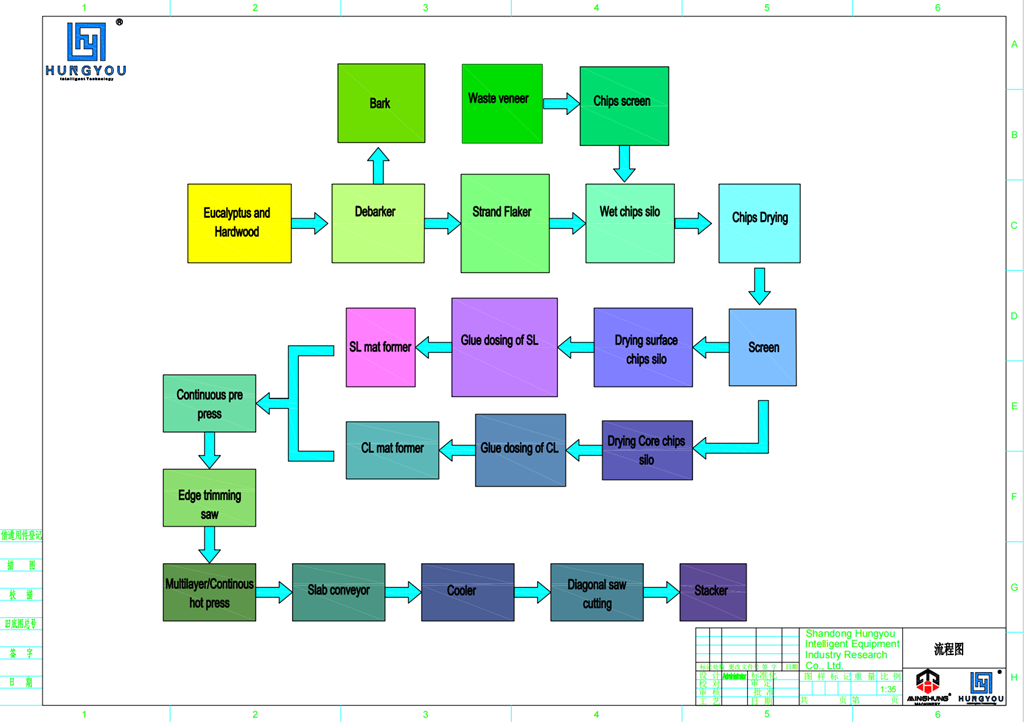

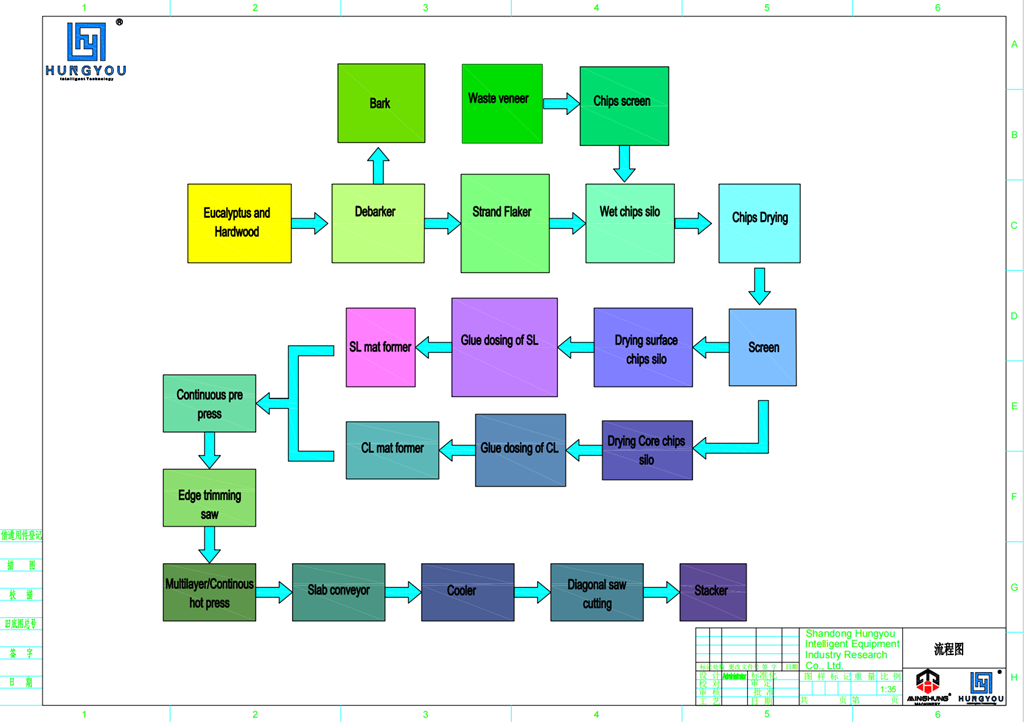

Working principle and process flow

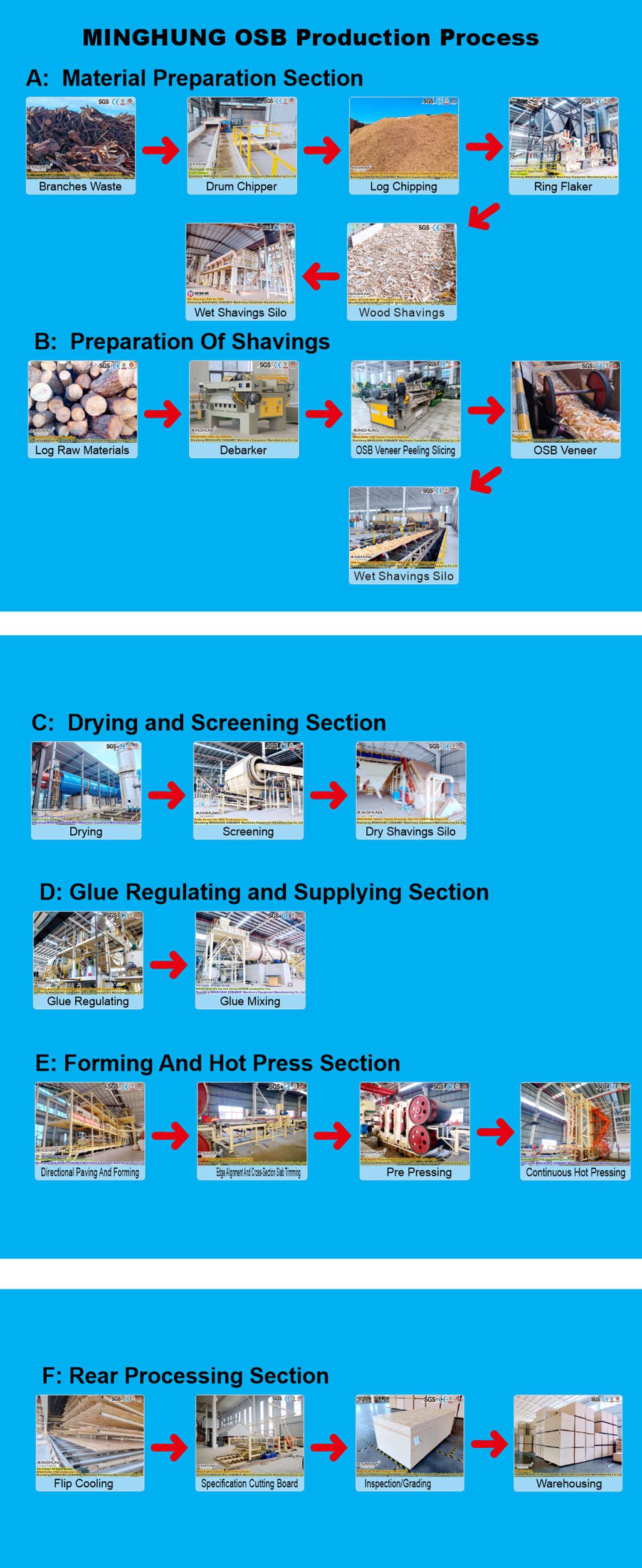

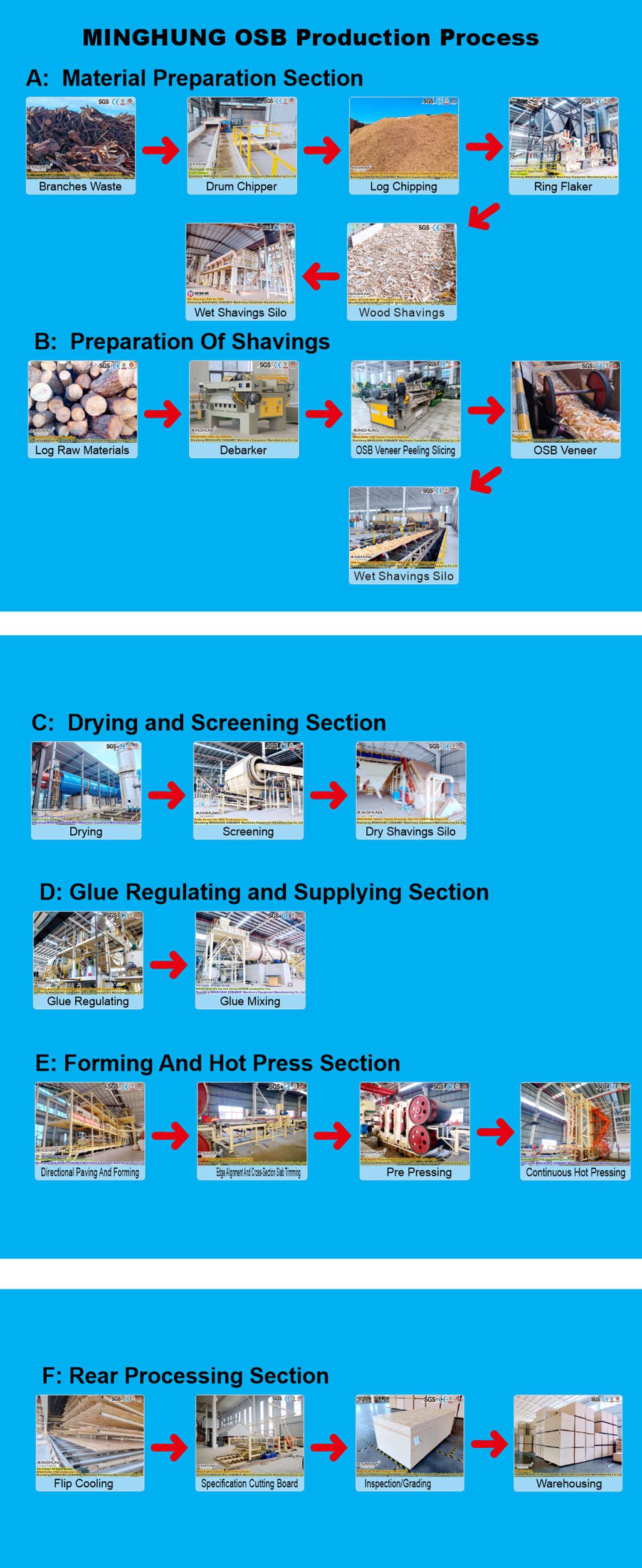

(1) Directed paving and pre-pressing

Directed paving:

OSB wood chips are divided into surface layer (longitudinally arranged) and core layer (transversely arranged), and are oriented by a special paving machine (such as a mechanical directional head or airflow paving system). The length of the surface layer wood chips is usually 50-100mm, and the core layer wood chips are shorter (20-50mm).

Pre-pressing and shaping:

The paved slab enters the pre-pressing machine (pressure 0.5-1.5MPa), and the air is removed and the direction of the wood chips is initially fixed by mechanical roller pressing or high-frequency pre-pressing to prevent the structure from loosening during the subsequent hot pressing process.

(2) Continuous hot pressing stage

High pressure zone (initial curing):

Temperature 210–230℃, pressure 3.0–5.0MPa, quickly close the slab and activate the adhesive (usually phenolic resin or MDI adhesive), and the surface wood shavings directional structure is initially cured.

Medium pressure zone (plasticization balance):

Temperature 200–220℃, pressure 2.0–3.5MPa, maintain full penetration of the core layer adhesive, and balance the curing rate of the inner and outer layers.

Low pressure zone (setting and stress release):

Temperature 180–200℃, pressure 1.0–2.0MPa, control the final thickness and release internal stress to avoid board warping.

(3) Cooling and post-processing

Cooling section:

The pressed sheet is cooled to below 50°C by a circulating water cooling system to stabilize the sheet size.

Cutting and sanding:

The sheet is cut into standard sheets using a high-speed sawing system, and the surface flatness is adjusted using a sander.

Core Structure and Composition

Hot press plate system: Composed of multiple heating plates, the interior is heated by heat transfer oil or steam to provide uniform temperature.

Steel belt system: Two circulating steel belts (upper and lower) hold the slabs and run continuously to ensure uniform pressure transmission.

Hydraulic system: Pressure is applied through hydraulic cylinders, and the pressing force in different areas can be adjusted in sections.

Control system: PLC or computer control, real-time monitoring of parameters such as temperature, pressure and speed.

Auxiliary equipment: includes paving machines, pre-pressing machines, cooling sections, sawing systems, etc.

1. Very High Production Efficiency: Continuous operation, no batch cycle time, significantly higher output per unit time than multi-opening presses, ideal for large-scale industrial production.

2. Exceptional Product Quality:

Minimal thickness tolerance, extremely high surface flatness.

More uniform and controllable density profile, superior and stable physical-mechanical properties (MOR, MOE, IB).

Excellent surface quality (contact with steel belt).

3. Superior Process Control: Highly flexible and precise control over temperature and pressure profiles, enabling better adaptation to different raw materials, resins, thicknesses, and performance requirements.

4. Lower Energy Consumption: Theoretically higher thermal efficiency than multi-opening presses (continuous contact reduces heat loss), potentially lower energy consumption per unit product.

5. High Automation: Reduces manual operation, improves production stability and safety.

You gotta consider your production capacity plan, product positioning, raw material situation, and investment budget when choosing the type of press and its specific technical specifications. Just tell us your needs and get the best quote.

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com