Wood-based panel hot pressing process

The production of various wood-based panels follows a specific production process.

Different types of wood-based panels have different hot-pressing processes in the product hot-pressing stage.

For example, in the production of melamine impregnated paper veneer, the hot pressing process

Generally divided into constant temperature (145 ~ 165 t ) pressurization, pressure holding (about 2 ~

3 MPa), three stages of pressure relief [1°]; while medium density fiberboard (MDF)

The hot pressing process of production is usually pressurization (3. 5 ~ 5. 5 MPa), decompression,

Pressure holding (1 MPa), secondary pressurization (1 ~ 1.5 MPa), five stages of pressure relief

Section , the temperature is about 160 ~ 195 where the pressurized pressure, temperature and

And hot pressing time and other process parameters also need to be based on raw material conditions, tree species, board

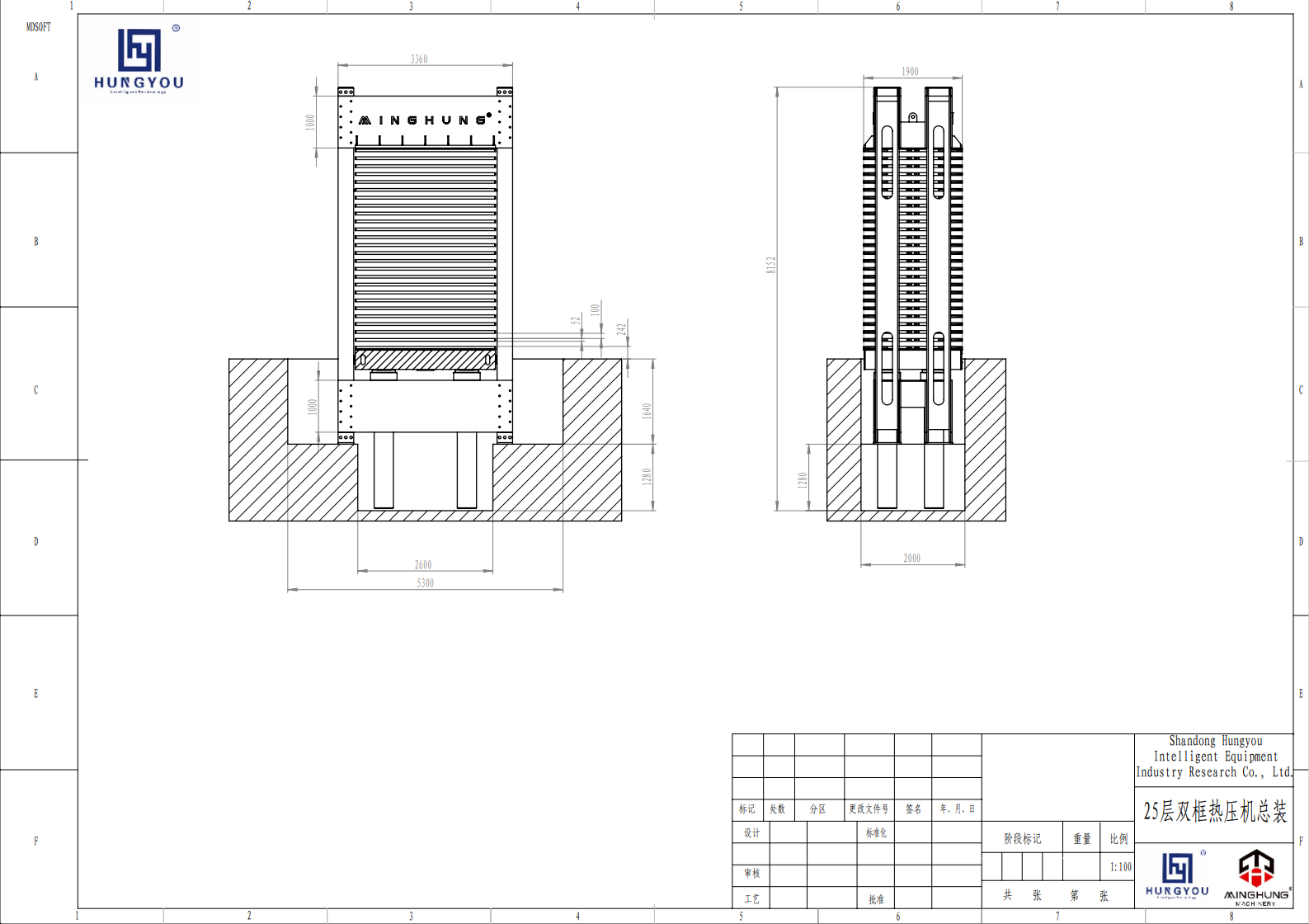

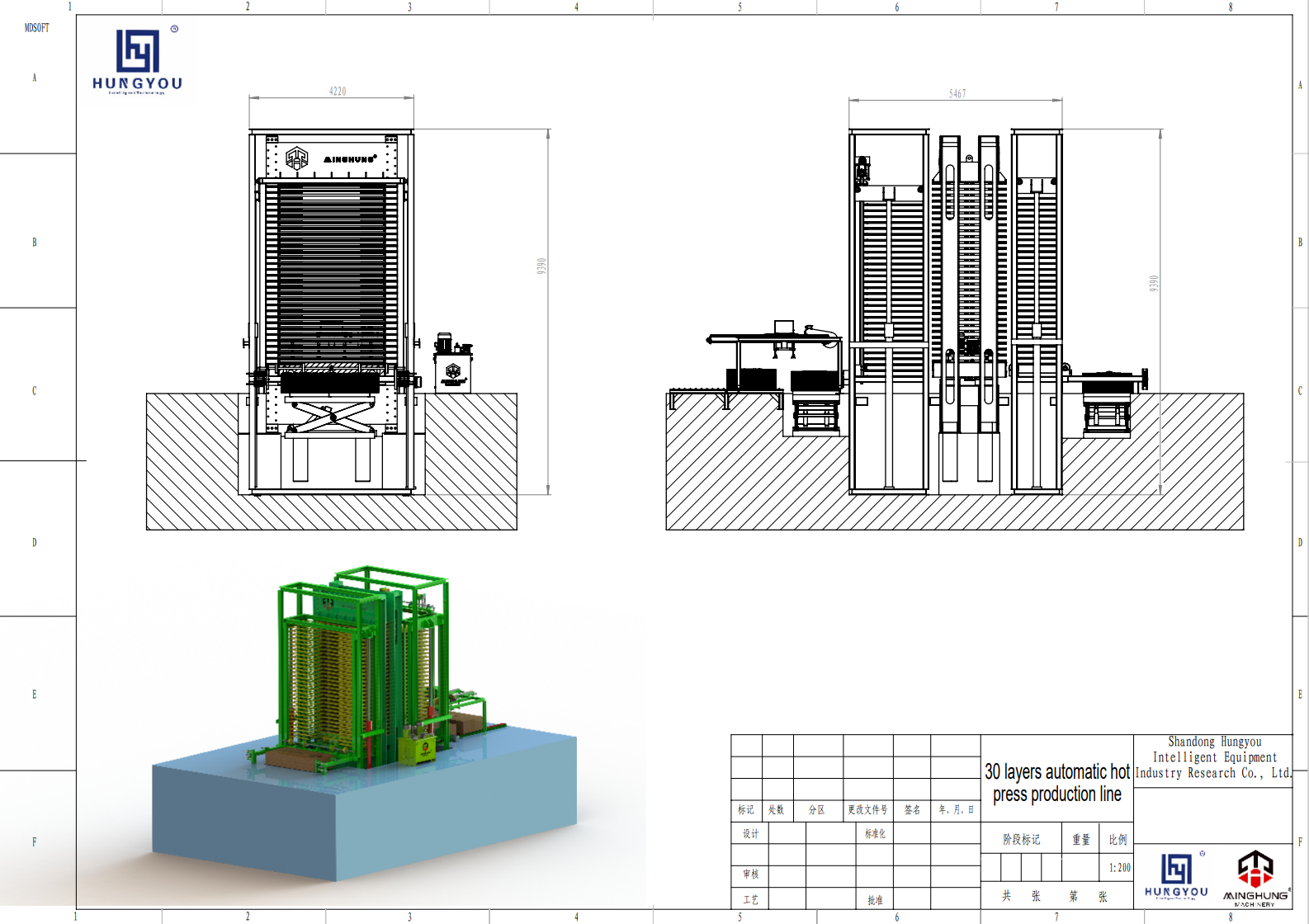

Billet moisture content, finished plate thickness, equipment type (multi-layer hot press/continuous heat

Press) and other conditions are adjusted appropriately [11^ 2].

In the hot-pressing production of wood-based panels, meeting the requirements of the hot-pressing process is the guarantee

The most important condition to ensure product quality is also the mechanical

The basic conditions and criteria that must be met in the design of structure and control system,

Discuss the working principle of the heat press machine necessary to achieve the heat press process of the product

needs as a prerequisite.

Whatsapp: +8618769900191 +8615589105786 +8615805493072

Email: minghungmachinery@gmail.com

Website: www.plywoodmachineline.com