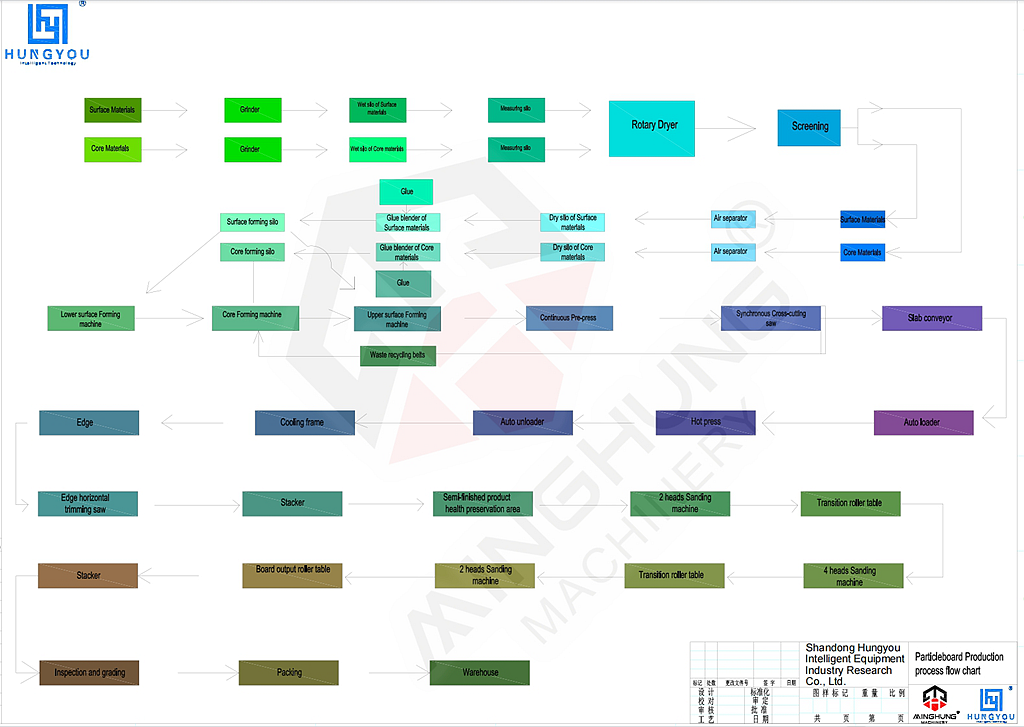

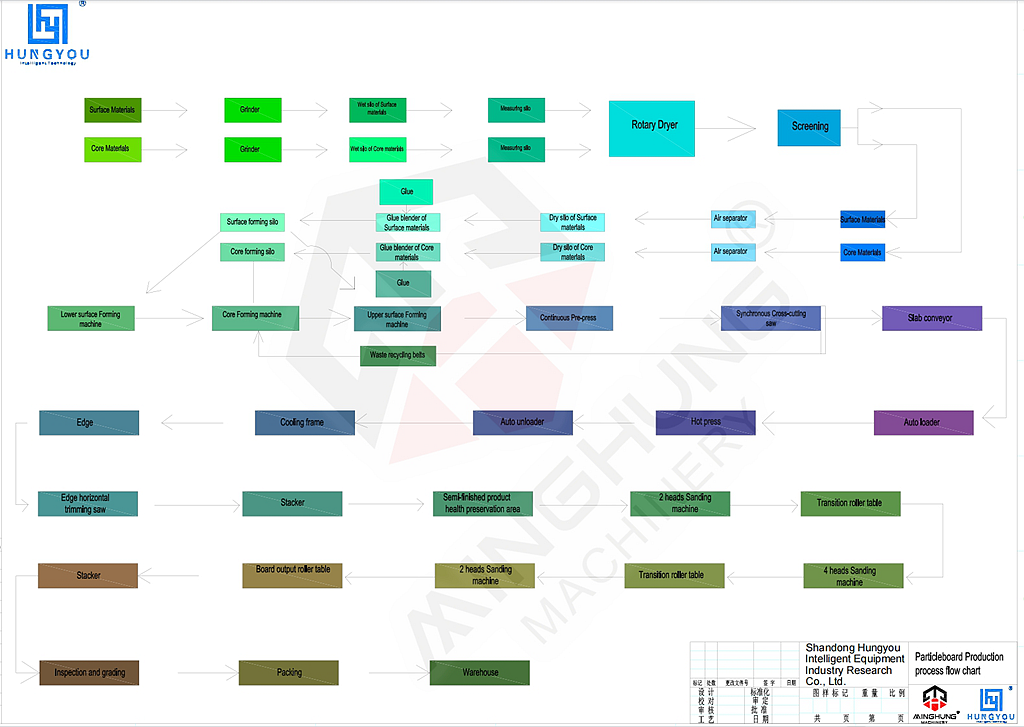

II. Production Process of Flame-Retardant Particleboard Base Material

1. Raw Material Preparation

Wood fragmentation:Fast-growing forest wood (poplar/cedar) is debarked, sliced, and screened to produce 20-40mm long and 0.2-0.5mm thick particle boards.

Drying:The drum dryer reduces the moisture content of the particle boards from 40-60% to 2-4% (temperature 120-140℃, to avoid carbonization).

wood chipper machine

particleboard drying system

2. Application of Flame Retardants

Types of Flame Retardants:

Liquid type: Ammonium phosphate solution (concentration 15-20%)

Powder type: Polyphosphate ammonium (APP) + Aluminum hydroxide (ATH) compound (ratio 1:1)

Application method:

Liquid: Ammonium phosphate solution (15-20% conc.) sprayed at 10-12% dosage

Powder: APP+ATH blend (1:1 ratio) mixed with UF resin (25-30% of resin solids)

3. Blending & Forming

Resin System:Modified UF resin (50-55% solids) + retardant, total adhesive 8-10% of dry flakes

Layered Forming:

Surface: Fine flakes (<0.3mm, 40% for smoothness)

Core: Coarse flakes (>1mm, 60% for stability)

4. Pressing

Pre-pressing:cold-pressed at 1-1.5MPa for 30s to 50% target thickness

Continuous Hot Pressing:

Parameter | Surface Layer | Core Layer |

Temperature | 180-185℃ | 170-175℃ |

Pressure | 3.5-4.0MPa | 2.8-3.2MPa |

Time | 20-25 sec/mm | (e.g., 240-300s for 12mm) |

pre press machine

continuous hot press