Wood Based Panel Plywood Making Machines From China Professional Factory

| What is Plywood? |

Plywood is a three-layer or multi-layer panel-like material made of wood segments cut into veneer or thin wood veneer sheets cut by wood square planing, and then glued with adhesive. Usually, odd layers of veneer are used, and the fiber directions of adjacent layers of veneer are vertically glued to each other.

Plywood is one of the commonly used materials for furniture, one of the three major panels of wood-based panels, and can also be used for aircraft, ships, trains, automobiles, buildings and packaging boxes. A group of veneers is usually formed by gluing each other vertically according to the direction of adjacent layers of wood grain, and usually the surface plate and the inner plate are evenly arranged on both sides of the central layer or the core of the board. A slab made of gelled veneers crisscrossed in the direction of wood grain and pressed under heated or unheated conditions. The number of layers is usually odd, and a few have even numbers. The difference of physical and mechanical properties in vertical and horizontal directions is small. Commonly used types of plywood are plywood, plywood and so on. Plywood can imp

rove the utilization rate of wood and is a main way to save wood.

The usual length and width specifications are: 1220×2440mm, and the thickness specifications are generally: 3, 5, 9, 12, 15, 18mm and so on. The main tree species are: beech, camphor, willow press, poplar, eucalyptus and so on.

| Plywood production steps |

How to make Plywood? What machines do you need? How to choose the suitable and good plywood machine? Let me tell you

For making plywood, from raw materials wood → Plywood, you need many different machines, it mainly include: Veneer making machine, Glue machine, Press machine, Cutting machine, Sanding machine. According to your plywood size, thickness, wood species, production capacity, and other factors, machine specification also can be different.

Now let me introduce each machine production step one by one

<1> Veneer production line

Veneer production line is the necessary and important machines for making wood veneer, and veneer is the material for making plywood. Therefore Veneers quality will directly affect plywood quality.

One complete veneer production line includes: Debarker, Veneer lathe, Log loader, and Automatic stacker

This veneer peeling line, just need 2 workers will be enough

According to your wood length, diameter, hard or soft wood, these veneer machine can be different parameters. For example, it can be 4feet, 5feet, 6feet, 8feet, 10feet or as your requires.

Debarker

Rotary veneer lathe

Automatic stacker

<2> Veneer Dryer

Veneer dryer plays an important role for veneer production, plywood production, and wooden furniture production. Its function for drying the original peeled veneers moisture. Why has to drying the moisture of veneer? Because kinds of wood has water content, usually 40%-70%, so the peeled veneer moisture is high too, obviously, it is not suitable for start next production step. This is why veneer dryer is required.

Now in the market, there mainly has three types veneer dryer, they are Roller veneer dryer, Mesh veneer dryer, and Press dryer. Each of them has its own features and advantages, according to your own conditions and budget, we can advise the most suitable one for you.

The first two dryer types Roller dryer and Mesh dryer, they looks similar, they can be designed to be different layers, width and length according to different drying capacity, and usually it is suitable for big production capacity.

For the Press dryer, its price more favorable, and cover less factory space

For veneer roller dryer and veneer mesh dryer, our dryer quality is on the top in China, we use advanced and mature production technology, to ensure dryer structure good and works good, and use high quality materials and spare parts, to ensure our dryer long life span.

Veneer roller dryer

Veneer mesh dryer

Veneer press dryer

<3> Automatic Core composer /Veneer joint machine

Veneer joint machine /Veneer sewing machine for sewing two or three or more pieces of wood veneers, to be one big size as your plywood size. And it will be used on the surface of plywood production, to improve your plywood quality, make plywood more balance.

But this machine is not have to necessary, if you are new beginner for plywood manufacturing, and you have the budget, you can first not choose this machine, it will not affect your plywood production.

For Automatic veneer core composer, there are two types, one is standard types, directly joint veneers to be plywood size and automatic stack it; Another type is as below pictures, it is L type veneer core composer with Teeth joint shape

<4> Double sides Glue spreading machine

Glue spreader's structure is simple, not complex, but it is necessary for plywood production. Its function for coating glue evenly on wood veneer surface, so workers will lay these glued veneer out to be required Plywood size.

Now most clients choose double sides glue spreader machine, because it can coat glue on both sides of veneer at the same time, high work efficiency

<5> Cold press machine

Cold press machine also be called pre-press machine, its function for pre-pressing the glued veneer plywood, make inside glue melt, let the plywood primary forming. So when you infeed plywood into hot press machine, it will be more easier, also the plywood quality will be better

The pressing time of cold press machine is not fixed, different plywood factory can be different press time as their own conditions, some press half a hour, some press one hour, some press three hours, some press one night...

Cold press machine can be different pressure, usually 400Ton, 500Ton, 600Ton are widely used

According to your plywood size, we will customize the table size for you

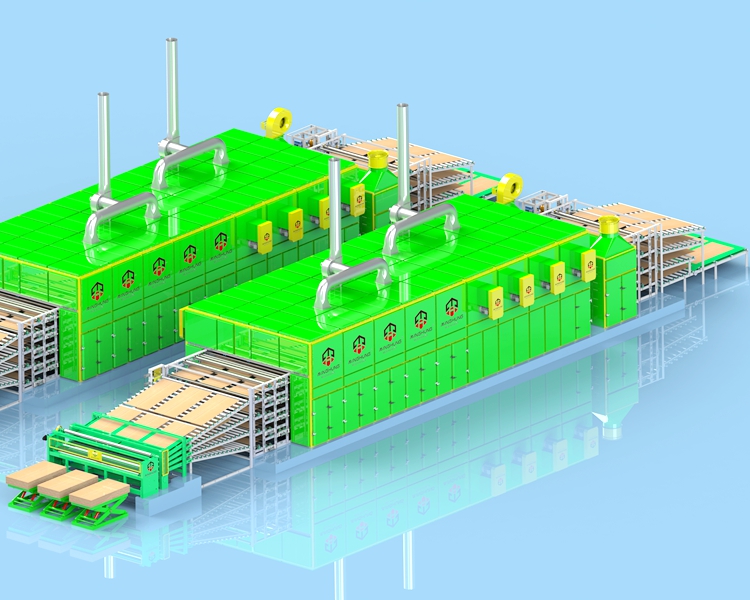

<6> Hot press machine

Hot press machine is very important for plywood production, it will affect and decide plywood quality directly.

Hot press machine can be different layers from 5-35 layers, and it can be different pressure like 500Ton, 600Ton, 800Ton, 1000Ton, 1200Ton

If you want less labors, then your hot press machine can equipped with semi auto loader and unloader or Fully automatic loader and unloader

<7> Plywood cutting machine /Plywood sizing machine

Plywood cutting machine for cutting and trimming plywood edge, make each pieces of plywood edge be clean and tidiness, and plywood size be same

Plywood cutting machine mainly has two types, one is this Semi automatic type, it is most widely used, price favorable; The another type is Fully automatic roller conveyor plywood cutting machine, no need workers, and speed faster, so production capacity bigger

<8> Film Hot press machine

If you want to produce anti-slip plywood, film faced plywood, then Film laminating hot press machine is necessary.

The film laminating hot press machine with semi auto loader, for laminating film paper on plywood surface.

<9> Plywood sander

Plywood sander is sanding and calibrating your plywood thickness, make it balance, improve quality; Also there has polishing machine for polishing plywood surface

If you want to produce high-end plywood, then the plywood sanding machine will be helpful

Sanding machine can be different specification, it can be single side, double sides, it can be two sanding heads, three sanding heads, and it can be different specification according to different production capacity

With these machines, and with Steam boiler or Oil boiler, you can start to produce plywood

| Who we are? |

Shandong MingHung Wood Machinery Co.,ltd is one famous and professional plywood machine factory in China, with many years production experience, advanced production lathe, professional workers and engineers, we can design and offer the suitable and good quality woodworking machinery for you.

We can offer all necessary woodworking plywood machinery for you to help you produce good quality plywood. and we insist only use good materials and spare parts, to ensure machine is strong and long life span.

Until now we have exported machines to different countries and got good feedback.

Welcome you contact us for more information of these wood based panel machine

| International fair we joined |

Turkiye fair

Mexico fair

Indonesia fair

| Our Plywood machinery loading to different Countries |

| Welcome contact us |

Mark: +86 18769900191

Ali: +86 15805496117

Lucinda: +86 15805493072

Email: minghungmachinery@gmail.com