Based on working principles and structure, plywood dryers are mainly categorized as follows:

1. Mesh Belt Continuous Dryer

Working Principle: This is currently the most mainstream and advanced model. The veneer or mat is carried by a stainless steel mesh belt and continuously passes through the drying chamber. The chamber is divided into multiple sections with independently controllable temperature and humidity. The veneer sequentially goes through preheating, high-temperature drying, moisture adjustment, and cooling stages to complete the drying process.

Advantages:

High Efficiency and Continuity: 24/7 uninterrupted production, high automation, extremely high production efficiency.

Excellent Drying Quality: Zonal control allows for a more rational drying curve; veneer is heated uniformly with minimal deformation.

Energy Saving: Utilizes hot air circulation and good insulation for high thermal efficiency.

Labor Saving: Automated feeding and discharging significantly reduce labor requirements.

Application Scenarios: Large, modern medium to large-scale plywood manufacturing enterprises.

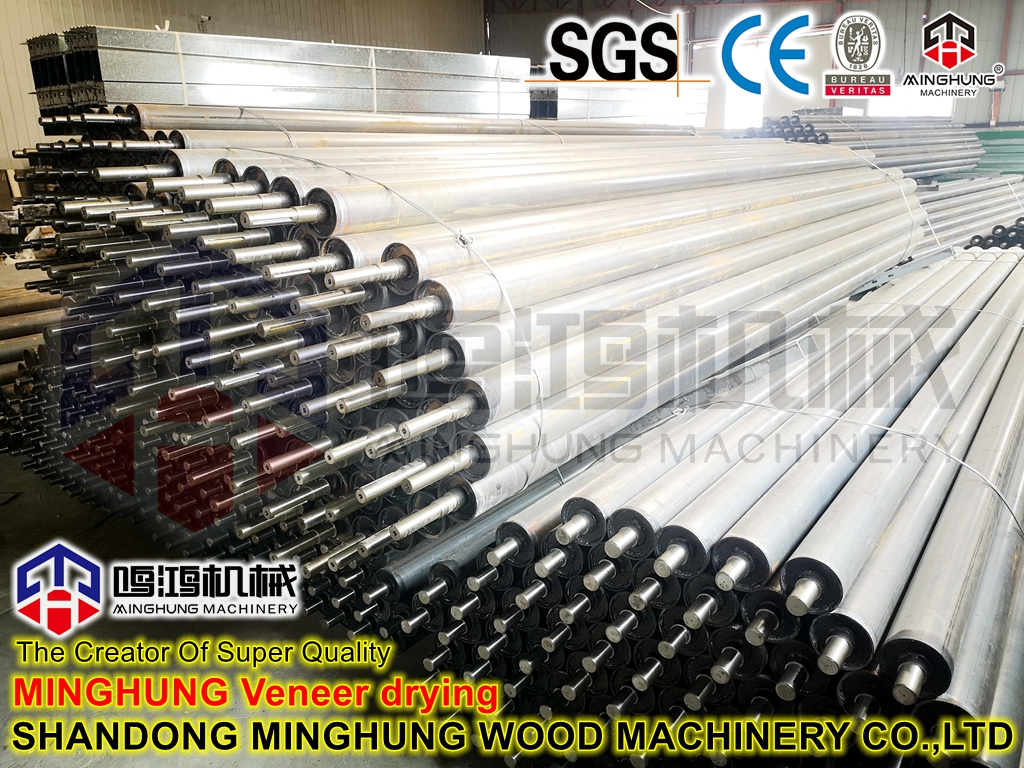

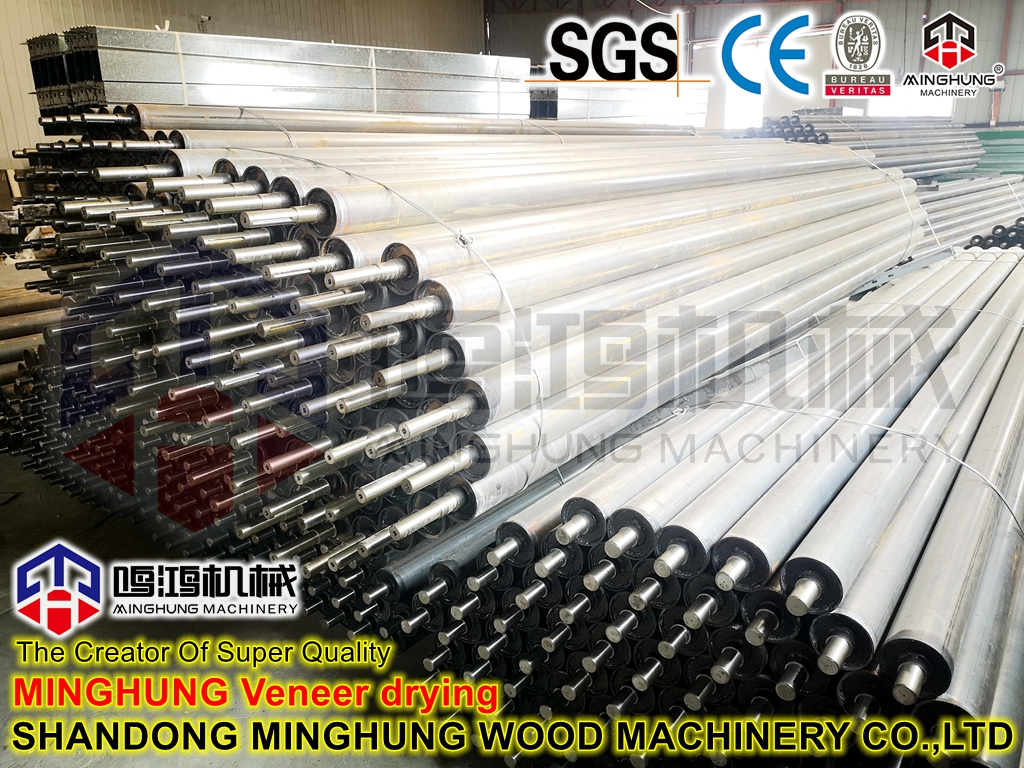

2. Roller Dryer

Working Principle: The veneer is gripped and conveyed forward by upper and lower staggered rollers while hot air is blown onto its surface from above and below for drying.

Advantages: Stable transmission, suitable for drying thinner veneers; was once very common.

Disadvantages: Rollers are prone to wear, less adaptable to veneer thickness, now gradually being replaced by mesh belt types.

3. Kiln Dryer

Working Principle: This is a batch-type drying equipment. Veneers or mats are stacked on carts and pushed into a sealed drying kiln for batch drying operations. The carts are pulled out after a cycle is completed.

Advantages: Simple structure, lower investment cost.

Disadvantages:

Low Efficiency: Time-consuming loading and unloading, unable to produce continuously.

Uneven Drying: Temperature and humidity differences exist within the kiln, easily leading to uneven drying.

High Labor Intensity: Low automation, requires significant manual operation.

Application Scenarios: Small wood processing plants or start-ups with limited budgets.

|

Core structure and systems

A modern mesh belt dryer typically consists of the following systems:

1. Conveying System: The core is a high-temperature resistant stainless steel mesh belt, supported by drive units, tensioning devices, and support rollers, responsible for smoothly transporting the veneer.

2. Heating System: Provides the heat source. Common methods include:

Steam Heating: Steam is provided by a boiler and heats the air via radiators. Most traditional, lower operating cost.

Hot Air Furnace Heating: Directly burns wood waste (e.g., bark, sawdust) to produce clean hot air. Very economical and environmentally friendly, a mainstream method.

Electric Heating: Uses electric heating elements. Precise temperature control but extremely high energy consumption, only used for small experimental equipment or special occasions.

Gas/Oil Heating: Burns natural gas or diesel. High thermal efficiency, convenient temperature control, suitable for areas without boilers but with convenient fuel supply.

3. Circulation Fan System: High-power, high-temperature resistant fans force hot air to circulate rapidly and evenly within the drying chamber, penetrating the veneer layers to ensure efficient heat exchange.

4. Moisture Exhaust System: Equipped with automatically adjustable exhaust dampers/intake dampers to promptly discharge high-humidity air from the chamber, maintaining drying momentum.

5. Insulation System: The chamber body is clad with high-quality insulation material (e.g., rock wool) to minimize heat loss and reduce energy consumption.

6. Control System: The "brain" of the equipment. Uses a PLC + Touchscreen to preset and store various drying process curves, monitor in real-time, and automatically adjust parameters like temperature, humidity, and mesh belt speed, enabling intelligent and visual operation.

|

Workflow

1. Loading: Wet veneers are neatly placed on the feed-end mesh belt by an automatic loader or manually.

2. Preheating Zone: The veneer is initially heated; the temperature should not be too high to prevent surface hardening which affects internal moisture evaporation.

3. High-Speed Drying Zone: Temperature rises to the highest, fans operate at full speed, moisture within the veneer is evaporated rapidly in large quantities.

4. Deceleration Drying Zone: Temperature is slightly reduced, air speed is adjusted to prevent over-drying or excessive stress in the veneer.

5. Moisture Balancing Zone (Optional): Steam spraying or humidity adjustment is used to balance moisture inside and outside the veneer, reduce internal stress, and prevent deformation during subsequent processing.

6. Cooling and Discharge: The dried veneer is cooled and then discharged from the outlet end, moving to the next process.

In conclusion, a plywood dryer is a significant investment. Choosing a technologically advanced, stable, energy-efficient, and high-performance dryer is a crucial step for plywood manufacturers to enhance product quality, reduce production costs, and strengthen market competitiveness.

|

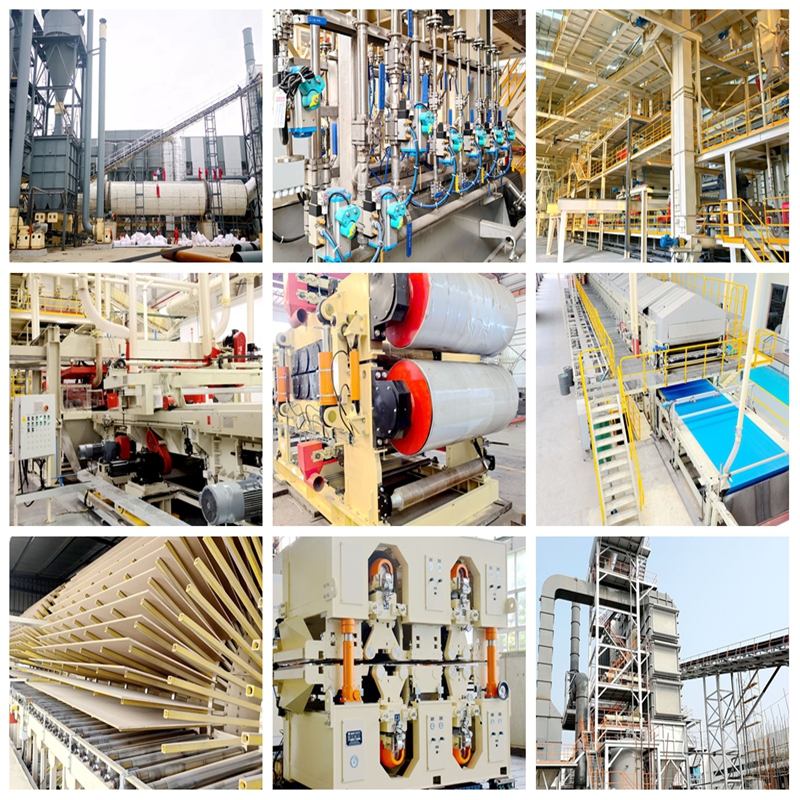

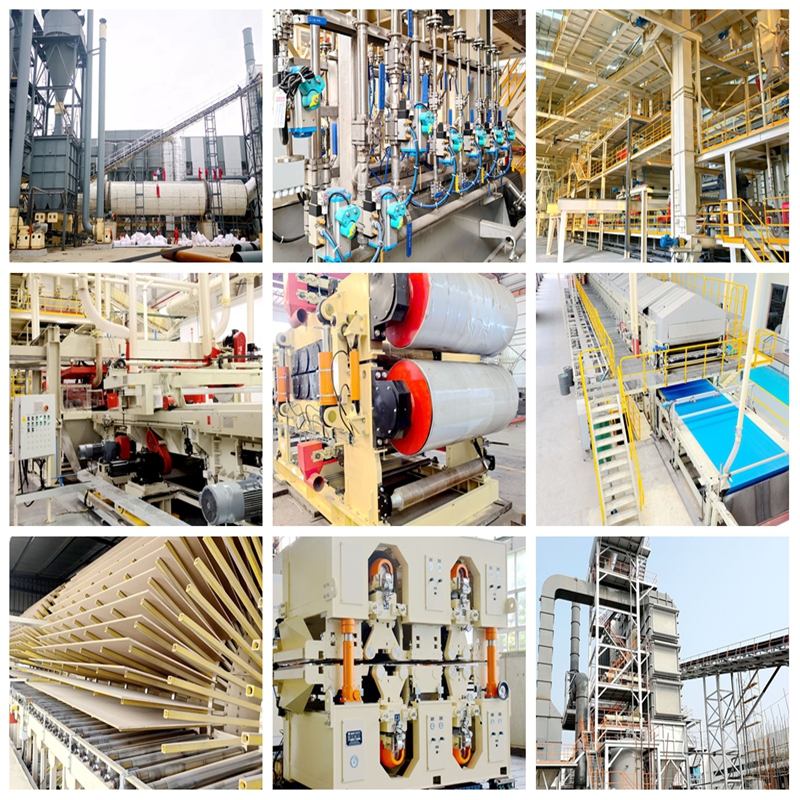

Company Profile

We are Shandong MINGHUNG Wood Based Panel Machinery Co.,Ltd China factory and manufacturer of full sets of Plywood machinery and Veneer machinery. With many years production experience, advanced production technology,experienced workers and professional engineers, we can offer you the suitable, good and strong machinery for you.

In addition to the plywood production line equipment, we also have the full-line production lines for particleboard and density board.

plywood production line

particleboard production line

density board production line

|

Loading vehicle photo

|

Exhibition photos

We includes factory layout design, installation, operator training, 24-month warranty, and global spare parts delivery within 72 hours.