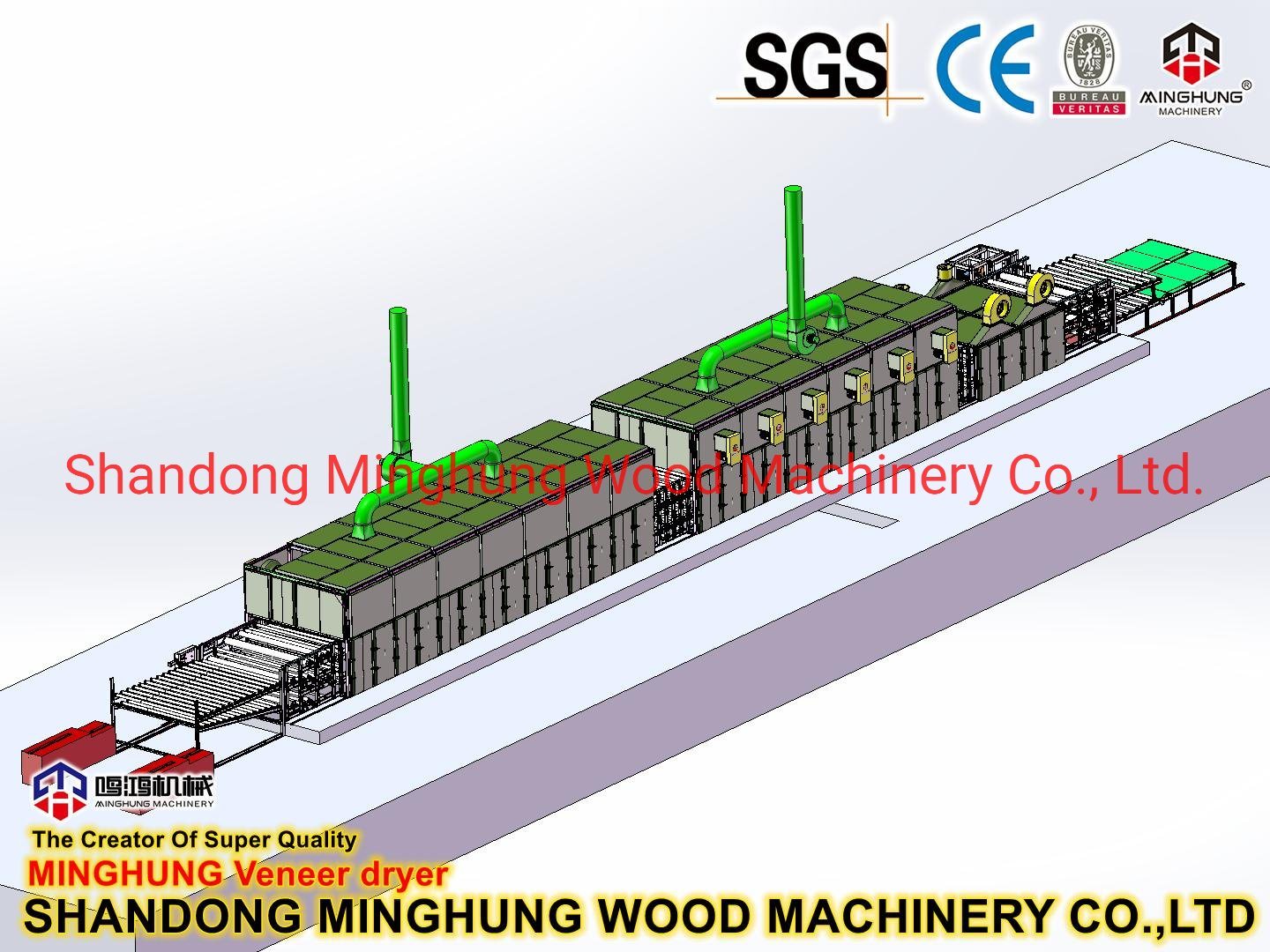

The Poplar Plywood Specialized Drying Machine is professionally developed for the characteristics of poplar wood. Poplar, being a relatively soft wood with high moisture content and prone to deformation, requires special process treatment during drying. This equipment effectively addresses issues such as deformation, cracking, and mold that often occur during the drying of poplar veneers through precise temperature and humidity control systems and poplar-specific drying curves, ensuring drying quality and production efficiency.

1. Intelligent Temperature and Humidity Control System

Uses high-precision sensors for real-time monitoring

PLC automatic adjustment system optimizes drying parameters

Supports multi-stage drying curve settings

2. Specialized Drying Chamber Design

Multi-layer staggered hot air circulation system

Stainless steel inner chamber, corrosion-resistant

High-efficiency insulation, heat loss less than 5%

3. Anti-Deformation Devices

Special pressure roller system maintains veneer flatness

Unique airflow guidance design prevents edge over-drying

Automatic leveling system ensures even heating

4. Energy-saving and Environmental Protection System

Heat recovery device saves over 30% energy

Low-noise design, operation noise below 65dB

Multiple heat source options (steam, natural gas, electricity)

Item | Specification |

Processing Size | 1220×2440mm (customizable) |

Drying Capacity | 20-30m³/day |

Drying Temperature | 40-120℃ adjustable |

Moisture Control | Final moisture 8%-12% |

Power | 15-45kW (depending on configuration) |

Heat Source Options | Steam/Natural Gas/Electricity |

Control System | PLC+Touch Screen |

The working principle of the Poplar Plywood Specialized Drying Machine is based on the deep integration of forced convection hot air drying and poplar material science. Its core is an intelligent process designed to address the characteristics of poplar wood: "soft texture, high moisture content, prone to deformation, and susceptible to mold."

The entire process can be summarized as follows: The intelligent system, based on a pre-set "Optimal Drying Curve for Poplar," controls the hot air (temperature, humidity, air velocity) to exchange heat and moisture with the poplar veneers. It maximizes drying efficiency while simultaneously inhibiting deformation and internal stress, ultimately producing high-quality veneers with uniform moisture content and excellent flatness.

The detailed process:

1. Preheating Stage (Preheating Zone): High-moisture wet poplar veneers entering the dryer are not immediately subjected to high-temperature drying. The system first uses medium-temperature, high-humidity hot air to preheat the veneers uniformly, slowly and evenly raising their overall temperature. This stage aims to prevent surface cracking caused by sudden high temperatures leading to rapid evaporation and shrinkage.

2. Constant Rate Drying Stage (Main Drying Zone): After the core temperature of the veneers increases, they enter the main drying zone. Based on poplar's properties, the equipment uses relatively high temperature and air velocity but strictly controls humidity. High-volume, high-velocity hot air uniformly passes through the gaps between veneers, carrying away free water molecules from the surface. The system maintains the kiln's humidity within an optimal range through intelligent dehumidification, ensuring drying speed while avoiding case-hardening.

3. Falling Rate Drying Stage (Conditioning/Balancing Zone): When the moisture content of the veneers drops below the fiber saturation point, moisture evaporation from the cell walls becomes more difficult. At this stage, the system appropriately reduces temperature and increases humidity. The key here is "conditioning treatment." By introducing slight steam or humidity adjustment, the internal stress generated during drying is relieved, balancing the moisture content between the interior and surface. This is the most critical step in preventing warping and deformation of poplar veneers.

4. Cooling Stage (Cooling Zone): The dried veneers are at a high temperature. Direct exposure to outside cold air could cause stress due to sudden cooling. The cooling system at the end of the dryer provides a controlled, gradual cooling process, safely lowering the veneers to near ambient temperature, stabilizing their condition before discharge.

Pervasive Intelligent Control: The PLC system, via temperature and humidity sensors throughout the zones, collects real-time data and compares it with the built-in "Poplar-Specific Drying Curve." It then automatically adjusts heater power, fan speed, damper opening, etc., ensuring the entire drying process strictly follows the scientific path optimal for poplar wood.

A complete Poplar Plywood Specialized Drying Machine consists of the following major systems:

1. Main Structure System

Insulated Kiln Body: Constructed from high-quality double-sided color steel plates with polyurethane foam insulation, forming a sealed tunnel structure to ensure excellent thermal performance and prevent heat loss.

Sealed Kiln Door: Usually an electric or pneumatic lift door with good sealing to ensure air tightness during operation.

2. Hot Air Circulation System

Heating Device: Options include steam heat exchangers, gas hot air furnaces, biomass hot air furnaces, or electric heaters, depending on factory conditions. It is the "heart" of the dryer, providing the necessary heat source.

Circulation Fans: Use high-power, high-airflow, high-temperature resistant centrifugal fans. Their role is to force hot air powerfully and evenly through every layer of veneers, ensuring no dead air zones, which is key to uniform drying.

Ducts and Nozzles/Baffles: Scientifically designed air ducts and airflow distribution devices (e.g., nozzles, baffles) ensure even air distribution across the kiln's cross-section, preventing local over-drying or under-drying.

3. Humidity Control System

Dehumidification System: Consists of dampers, exhaust ducts, and exhaust fans. It automatically opens and adjusts the opening based on PLC commands to expel high-temperature, high-humidity air from the kiln in a timely manner, maintaining the required humidity gradient for drying.

Steam Spray System (Optional/For Conditioning): During the falling rate stage, if humidity needs to be increased for conditioning, this system can inject fine steam into the kiln, effectively preventing cracking and deformation of poplar veneers.

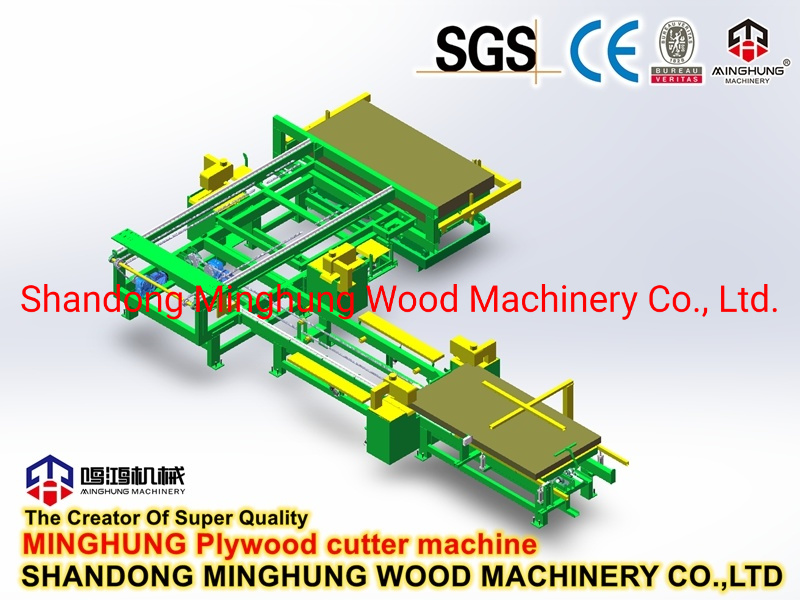

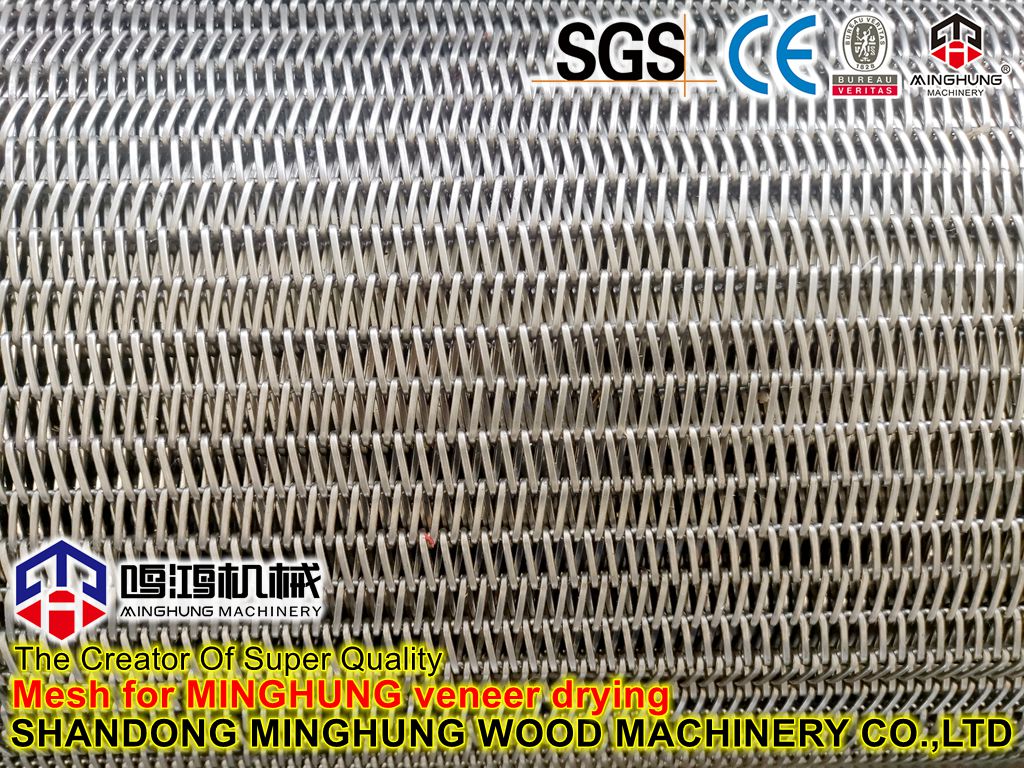

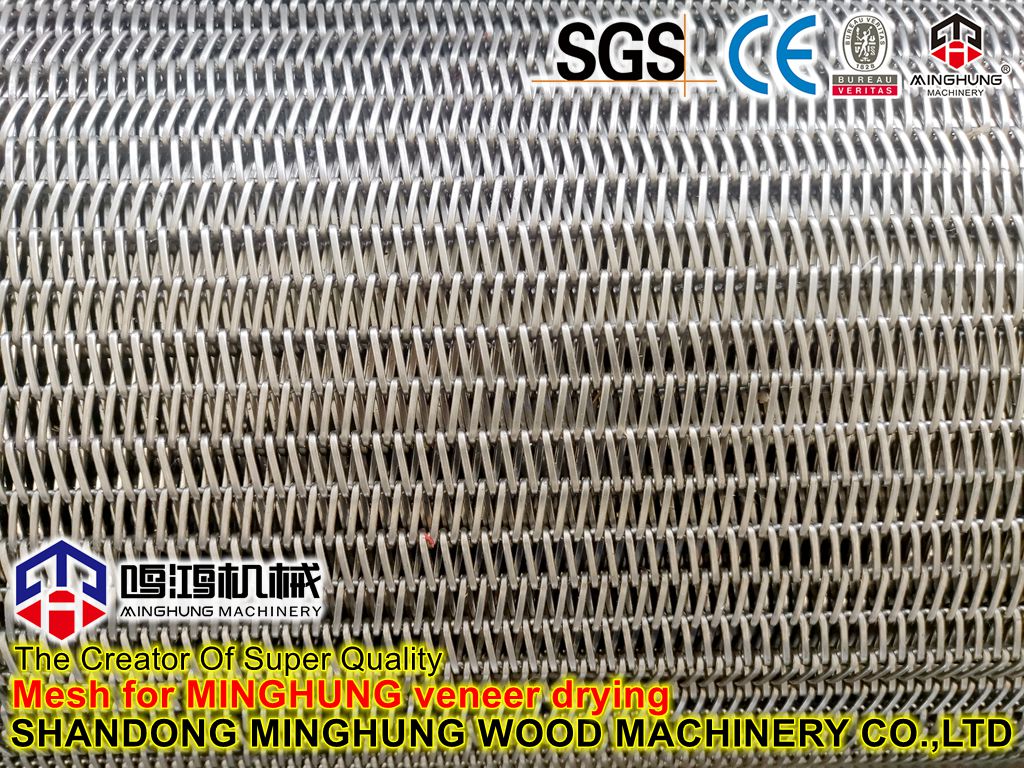

4. Material Handling System

Conveyor Roller Bed/Mesh Belt: Responsible for carrying and smoothly transporting the drying trolleys loaded with poplar veneers or directly conveying the veneers. The speed is controlled by variable frequency drives (VFDs), allowing precise control of drying time.

Drying Trolleys/Carts: Sturdy metal carts used for stacking veneers, facilitating loading and unloading.

5. Intelligent Control System (The Brain)

PLC (Programmable Logic Controller): The core control unit responsible for executing logic operations and outputting commands.

HMI (Human-Machine Interface): Typically a color touchscreen, serving as the interface for user interaction with the equipment. Used to set, modify, and call drying curves, and displays all parameters in real-time (temperature, humidity, air speed, operational status).

Temperature & Humidity Sensors: Precisely monitor the real-time temperature and humidity in various areas of the dryer and feed the signals back to the PLC.

Actuators: Include power regulators for heaters, VFDs for fans, motors for dampers, etc. They receive commands from the PLC and act accordingly.

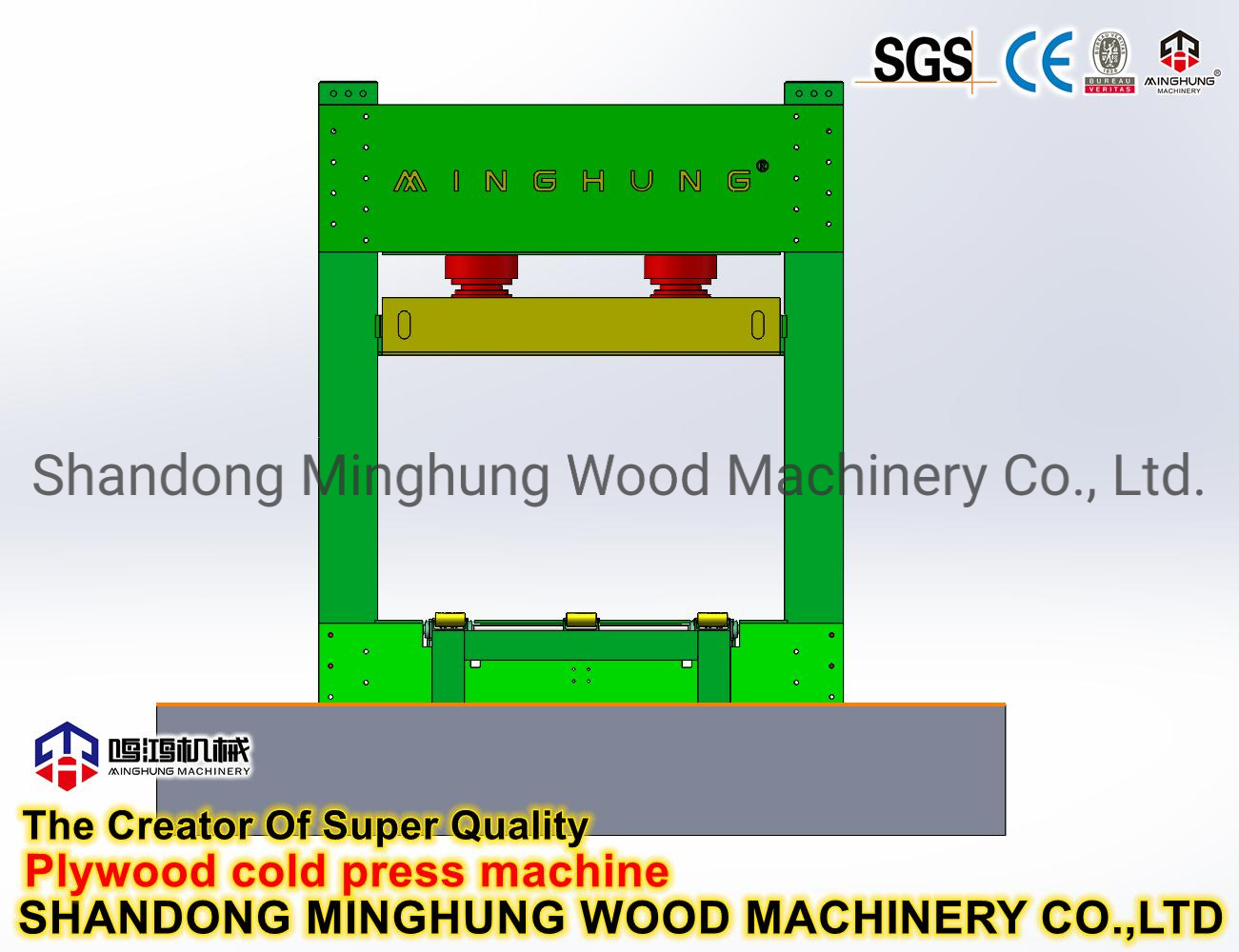

6. Anti-Deformation Auxiliary Device (Key Poplar-Specific Design)

Pressurizing Mechanism: Adjustable pressure beams (press roller chain system) are set above and below the veneer stack. They apply appropriate pressure to the stack during drying, effectively suppressing warping and deformation. This is the core mechanical device for ensuring the flatness of poplar veneers.

1. Poplar-Specific Drying Process

Built-in poplar drying curves optimized through extensive experiments. The intelligent system automatically adjusts temperature and humidity parameters based on the initial moisture content of poplar wood, preventing quality issues such as cracking and deformation during drying.

2. Anti-Deformation Design

Utilizes a multi-layer staggered airflow distribution system to ensure even heating on both sides of poplar veneer. Combined with special pressure roller devices, it effectively maintains veneer flatness.

3. High-Efficiency Energy Saving System

Equipped with heat recovery device, reducing energy loss. Energy saving exceeds 30% compared to traditional drying equipment, significantly reducing production costs.

4. Intelligent Control

Adopts PLC + touch screen control system, displaying drying parameters in real time. Supports data storage and remote monitoring, with user-friendly operation.

5. High-Quality Materials

The inner chamber is made of stainless steel with excellent corrosion resistance and long service life, ensuring clean and hygienic poplar veneer.

Applicable Specifications: Can process common sizes such as 1220×2440mm

Drying Capacity: 20-30 cubic meters of poplar veneer per day

Heat Source Options: Supports various heating methods including steam, electricity, and gas

1. Excellent Drying Quality

Moisture uniformity over 95%

40% improvement in veneer flatness

Effectively prevents mold and discoloration

2. Significant Energy Saving

30%-40% energy saving compared to traditional equipment

Heat recovery efficiency reaches 85%

Automated operation reduces labor costs

3. Easy Operation and Maintenance

7-inch touch screen with user-friendly interface

Fault self-diagnosis system

Modular design for easy maintenance

This equipment is specially designed for poplar plywood manufacturing enterprises, suitable for: Poplar veneer drying、Poplar substrate processing、Plywood pretreatment、Wood product manufacturing.

We maintain a long-term cooperation with a well-known freight forwarding company, and adhere to the customer-first philosophy. We strictly implement the quality inspection process before shipment to ensure that each batch of products meets international quality standards, We deeply understand that high-quality service is the cornerstone of winning customer trust, and we always create value for customers with professional and efficient supply chain management.

Q:What after-sales services can we provide?

A:After-Sales Service & Support

Global Delivery: Export packaging (wooden case/steel frame) provided, supports CIF/FOB terms, assists with customs clearance documentation.

Installation & Commissioning: Dispatch experienced engineer teams to the customer's factory for installation guidance, equipment commissioning, and trial production.

Technical Training: Comprehensive theoretical and practical training for customer's operators, maintenance, and management staff until they can operate independently.

Warranty Commitment: 12-month warranty for the whole machine, lifelong technical consultation and paid spare parts supply.

Remote Support: 7x24 online technical consultation available, with remote diagnostics and troubleshooting via video call.

Shandong MINGHUNG Wood Based Panel Machinery Co.,Ltd Located in Xiaogezhuang Industrial Zone, Yitang Town, Lanshan District, Linyi City.

The machines we can offer includes: Wood chipper, Ring flaker, Strander, Wet silo, Drum dryer, Dry silo, Glue dosing and applying system /Glue blender, Mat forming, Continuous Multi-rolls pre-press, Multi opening hot press and Continuous press, Auto edge cutting machine line, Sanding machine line, kinds of related belt conveyor and so on.

Q:How long the production time?

A:If one set machine,3-4 months;If the full production line 6-8 months.

Q:What are your advantages?

A:We have rich experience in the market, with the same cost, we do better because we have strict control of the production process. We have an independent inspection department to check the quality.

Q:How is your quality?

A:As an experienced manufacturer, the quality of our machines can be guaranteed and we have supplied our products to thousands of customers all over the world.

Q:Can you customize products for customers?

A:Yes, we can customize products according to customer requirements or drawings. At the same time, we protect customers' business privacy with the strongest awareness.

Request a Quote Today! OEM/ODM solutions available – Start your plywood business with competitive edge!

Our contacts:

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com