China Top Veneer Dryer- Roller Dryer & Mesh Dryer for Plywood factory

Veneer dryer is one very important production step for making plywood, it will drying the peeled veneer moiture, make the dryed veneer moisture is suitable for to do next production step. If without drying, your peeled veneer will be not suitable for making plywood or wooden furniture, because its moisture is very high, different wood species' water content will be different, usually between 40-70%, such high humidity will directly affect your final product quality bad. Therefore, Veneer dryer is very important and necessary.

Now with the market development and clients feedback, roller dryer and mesh dryer become more and more popular. Because they can satisfy big drying capacity and the dryed effect is very good.

From outlooking, veneer roller dryer and veneer mesh dryer looks very similar, the most difference is their inside, roller dryer convey veneers by rollers, mesh dryer convey veneers by mesh belt. Both of them can be designed and produced to be different layers, width and length according to different customers requirements. and one set roller dryer or mesh dryer,, it can satisfy 40m3-100m3 production capacity, also we can customize the veneer roller dryer to satisfy higher drying capacity.

Now there are so many different dryer suppliers on the market, how to choose the really good Dryer for help your business going better?

now in China market, you can easy find many dryers from different supplier and different price. Because we are China manufacturer of veneer dryer, so we have analyze and know clearly that there are really very very few suppliers who can offer one really good working veneer dryer, most of them lack of production technology, after work half a year or one year, their dryer will has kinds of problems, this will waste much your maintain time and affect your product quality.

Now our Veneer dryer is on the top in China, excecpt we keep to improve our dryer by learned worlds mature production technology and improve our dryer according to many our customers feedback, we also insist use good materials and spare parts to ensure our dryer is heavy and strong. what we pursue is not just compare with Chinese dryer suppliers, we want to be one of very famous dryer supplier in the world, this is why we insist make it very good.

And the fact proves that what we insist is correct, because our customers are very satisfied of our dryer, some of them has bought two or three big roller dryer and introduced other people to us.

Now let me introduce our veneer dryer to you

Veneer roller dryer

Veneer roller dryer can drying different veneer species like birch veneer, beech veneer, pine veneer, eucalyptus veneer, and others.

It can be designed and produced to be different drying decks, width and chambers as your own requires, whatever your drying capacity is 30m3/per day, 50m3/per day, 70m3/per day or more, it is no problem, we can customize it for you.

Veneer mesh dryer

Veneer mesh dryer also is suitable for different veneer species, and it also suitable for face veneer except core veneer.

It also can be designed to be different drying decks, length and width as different demands.

Both dryer are very good, some clients like roller dryer, some clients like mesh dryer.

Semi auto loader

Semi auto loader will convey veneer to different dryer layers automatically, so it will improve work efficiency and production capacity.

High quality spare parts of our veneer dryer

Power system

Big fan

Thicken door

Good materials radiator

Good and strong rollers

Accessories

Specification of 3 layers vs 4 layers Veneer roller dryer

| Layers | 3 | 4 |

| Drying width | 3200mm | 3200mm |

| Veneer thickness | 1-2mm | 1-2mm |

| Heating section | 11kw | 15kw |

| Original moisture | 50-60% | 50-60% |

| Dryed moisture | 8-10% | 8-10% |

Note: Dryer specification will be offered as your own conditions

MINGHUNG Veneer dryer in our customers factory

Different our customers drying different veneers, some use beech veneer, some use poplar veneer, some use birch veneer, all got good drying effect. This encourage us continue to make our dryer quality better and better, help more customers business going better.

MINGHUNG MACHINERY Introduction

MINGHUNG group mainly has two subsidiary corporation, one for making Plywood production machines, one for making Particle board production line, MDF production line, and Veneer production line.

For Shandong MingHung Wood Machinery, we can offer you all machines for making plywood from wood. Machines includes veneer making machine, veneer drying machine, core composer, plywood lay out machine, glue spreader machine, cold press machine, hot press machine, film laminating hot press machine, plywood sizing machine, calibrating and sanding machine, panel overturn machine, lfit table and so on

For Shandong MingHung Wood Machinery, we can offer you all machines for making plywood from wood. Machines includes veneer making machine, veneer drying machine, core composer, plywood lay out machine, glue spreader machine, cold press machine, hot press machine, film laminating hot press machine, plywood sizing machine, calibrating and sanding machine, panel overturn machine, lfit table and so on

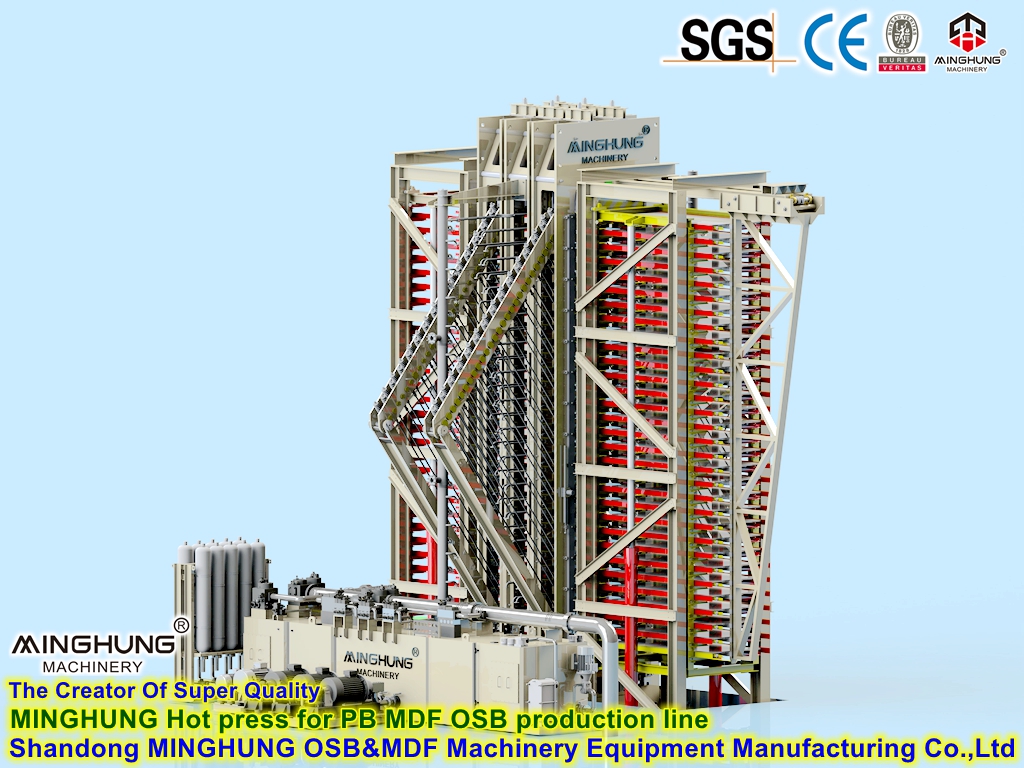

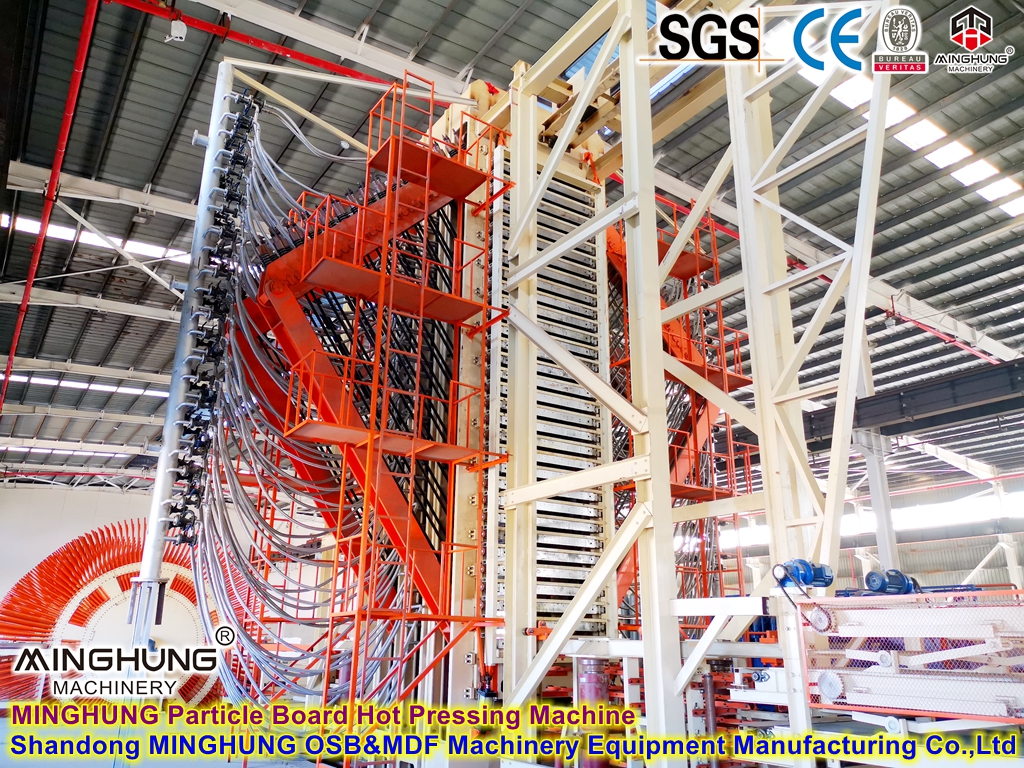

For Shandong MingHung OSB&MDF Machine, we can offer you all machine for making chipboard, OSB board, and MDF board. According to different production capacity and panel size, we can offer the suitable wood based panel making machine for you.

Until now, MINGHUNG has developed long time since boss Mark's grandfather, now Mark Zhai as the big boss to own the MINGHUNG group. He insist and require all workers, serious treat each clients, use good materials, and strictly monitor each production step.

Until now, we have exported machines to different countries and got good feedback.

What we want is offer good quality machines to our customers, and help them create much more value.

Once you choose our machines, we will be responsible for you and offer long life span service

CE Certificate

We have the CE certificate and documents for all of these wood based panel machine, so no need worry to import our machines.

MINGHUNG Machine drawings

We have professional technology department, to help you design factory layout, offer professional advise for machine position. And before machine arrive to your factory, we will offer the necessary machine foundations like hot press machine, cold press machine, film hot press machine and so on

MINGHUNG Other Plywood Machine

Multi-layers automatic Hot press machine

Hydraulic Cold press machine

Rotary veneer lathe

Contacts

Mark: +86 18769900191

Ali: +86 1580546117

Lucinda: +86 15805493072

Email: minghungmachinery@gmail.com

Welcome contact us,, we will quickly reply you and show more infromation

For Shandong MingHung Wood Machinery, we can offer you all machines for making plywood from wood. Machines includes veneer making machine, veneer drying machine, core composer, plywood lay out machine, glue spreader machine, cold press machine, hot press machine, film laminating hot press machine, plywood sizing machine, calibrating and sanding machine, panel overturn machine, lfit table and so on

For Shandong MingHung Wood Machinery, we can offer you all machines for making plywood from wood. Machines includes veneer making machine, veneer drying machine, core composer, plywood lay out machine, glue spreader machine, cold press machine, hot press machine, film laminating hot press machine, plywood sizing machine, calibrating and sanding machine, panel overturn machine, lfit table and so on