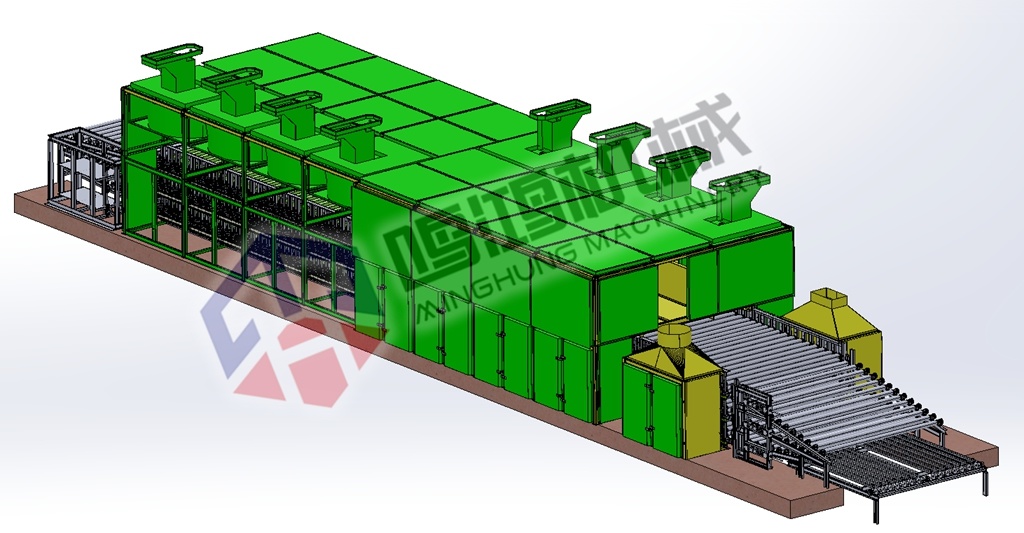

Veneer is a thin slice of wood made by rotary cutting or slicing of the log. The appearance of veneer varies and it depends on how the log is cut. The process of the veneer production in mill starts as the timber logs brought in by trucks are measured, sorted and stored by quality. Before the peeling process, wood must be softened in order to cut it into smooth veneer of even thickness, so the logs are soaked in 40 ⁰ C temperature water for two days. Moist, warm and debarked logs are rotary cut into thin layers called veneers after careful measuring and cutting of the logs. Long but thin slices of wood appear. The drying process as full veneer mats or clipped sheets follows for 4-5 minutes under pressure in 170 ⁰C hot air. Wood changes dimensions when it dries or absorbs water. Therefore, to produce a stable and high quality product, drying has to reduce the moisture content to the right level prior to further processing. After drying, veneer sheets are inspected for any defects such as split-ends, knot holes, loose knots, color defects etc. and sorted by quality. The veneer sheets are then packaged or mainly sent to next working line – for producing plywood.

Plywood is a wooden panel composed of thin cross-bonded veneers glued together. For greater strength properties the veneers are usually laid crosswise. Plywood panels are composed of at least three veneer layers. After veneer sheets drying and sorting procedure, jointing in length and width, surface veneer patching the gluing process follows. Veneer sheets are run through gluing machines – roller or curtain gluing. Glue is applied on veneers, which are layed so that the stack alternates. Pressing, which at first is done by cold press and followed by hot press, occurs after gluing and stacking of the veneers. Cold pre-pressing is done to flatten out the veneers and ensure the glue is distributed across the veneers evenly. Following the hot pressing in 130 ⁰C temperature, the glue reaction ends and bonding is achieved. Further on boards are sent to cut-to-size, sanding and grading to ensure that the dimensional properties and quality of the boards is according to the standards and agreements. Plywood can then be overlayed with various coating materials – phenolic and plastic. Coatings improve the plywood’s resistance to wear impact, chemicals and weather. Films and laminates imprinted with various patterns improve the panel’s frictional properties.

Quality control is performed continuously throughout the process and to final