1. Core Design Features & Advantages

Purpose-Built Adaptive Design: Optimized mechanical structure and cutting angles for plantation wood traits (small diameter, fast growth, relatively soft texture) to reduce splitting and enhance veneer surface smoothness and integrity.

Dynamic Pressure Compensation System: Utilizes smart sensors to monitor wood resistance in real-time, automatically fine-tuning knife pressure and feed speed. This effectively copes with wood density variations and knots, ensuring a continuous and stable peeling process with veneer thickness tolerance within ±0.02mm.

High Efficiency & Quick Changeover: Equipped with a quick knife change and spindle adjustment system, significantly reducing setup time between processing logs of different specifications. This improves overall equipment effectiveness (OEE) and meets high-volume continuous production demands.

Intelligent Data Management: Built-in production data logging system tracks processing parameters, yield rate, and thickness consistency for each batch, providing data support for process optimization and cost accounting.

Item | Parameter / Description |

Suitable Log Diameter | Small-Diameter Range: 80mm - 350mm (Core Advantage Range) |

Max. Peeling Length | 1300mm, 1650mm, 2600mm (Optional) |

Peeling Thickness Range | Ultra-Thin Range: 0.1mm - 3.0mm (adjustable) |

Thickness Accuracy | ≤ ±0.02 mm |

Spindle Speed | Variable speed, up to 300 rpm |

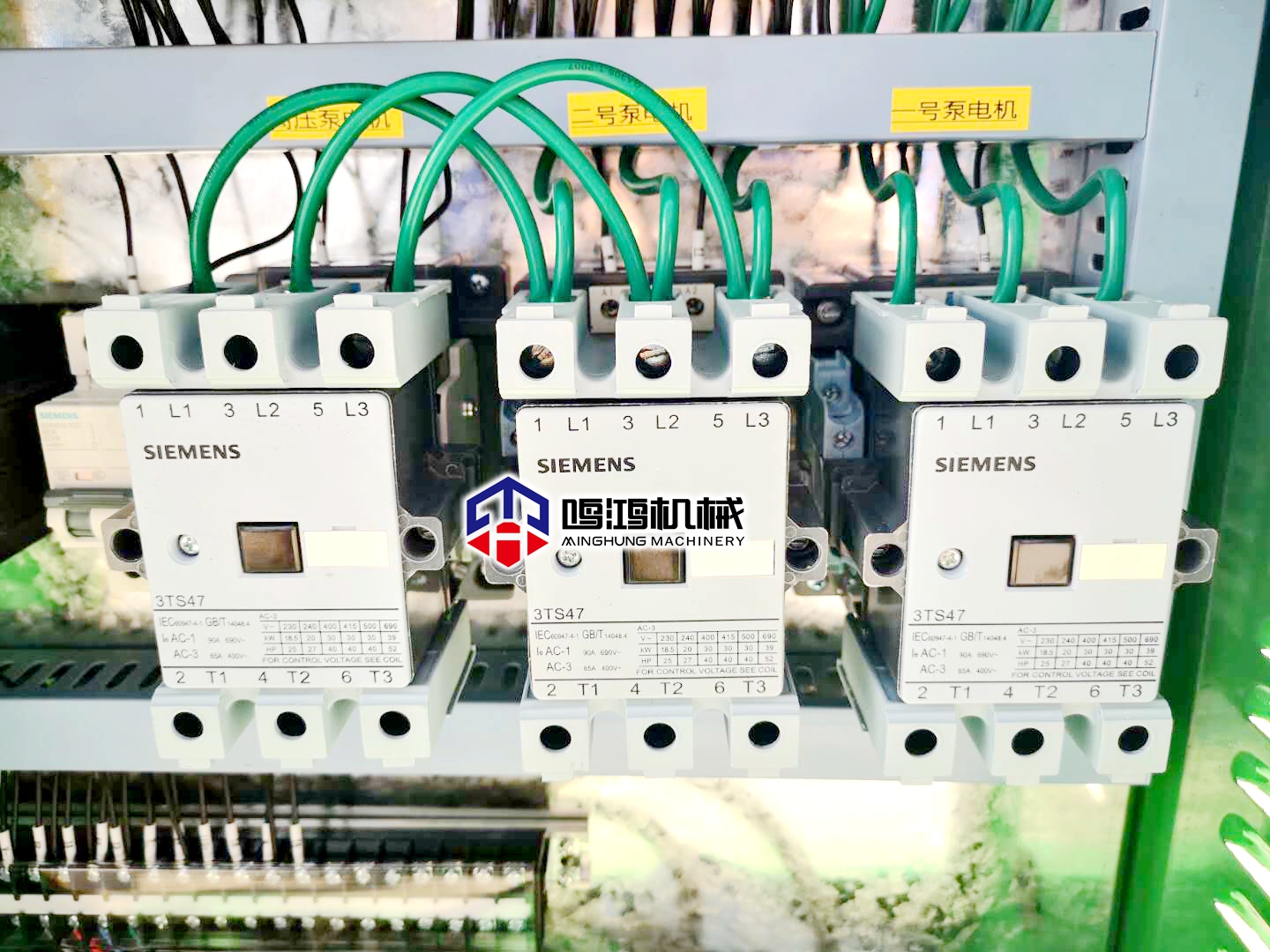

Control System | Industrial PLC + Color Touchscreen HMI |

Core Drive | AC Servo Motor for carriage feed |

Key Functions | Automatic centering, fixed-thickness peeling, length setting, fault diagnosis |

This machine is optimized for small-diameter, fast-growing plantation timber, featuring an automated work cycle that balances efficiency and material adaptability.

Core Process:

1. Log Loading & Centering: The cut log (e.g., eucalyptus, poplar) is loaded into the machine center. The automatic centering function activates to align the log's rotational axis with the spindle center, which is critical for high yield from small-diameter logs.

2. Clamping & Driving: The tailstock advances to clamp the log jointly with the headstock. The spindleless friction roller drive rotates the log, eliminating end damage caused by traditional spindles and making it ideal for small-diameter logs and cores.

3. Intelligent Peeling & Dynamic Compensation:

The carriage carrying the peeling knife feeds precisely and steadily towards the rotating log based on the set thickness.

Key Phase: The Dynamic Pressure Compensation System activates. Sensors monitor peeling resistance and log conditions (e.g., encountering knots) in real-time. The system instantaneously fine-tunes knife pressure and feed speed to prevent veneer breakage or thickness variation, ensuring a continuous and stable peel.

4. Veneer Conveying & Thickness Monitoring: The continuous veneer ribbon is smoothly discharged and passes through a thickness sensor. Data is fed back to the control system in real-time for closed-loop quality control.

5. Fixed-Length Cutting & Winding/Stacking: When the veneer reaches the preset length, the cutting device automatically activates to sever it. The finished veneer can be directed to an automatic winder or stacking platform based on downstream process requirements.

6. Core Processing & Cycle Completion: When the log is peeled down to a preset minimum diameter (e.g., 45mm), the carriage rapidly retracts, the tailstock releases, and the remaining core is automatically ejected. The machine resets, ready for the next cycle.

(1) Dedicated Mechanical Structure System

High-Strength Bed: Reinforced design to resist higher-frequency vibrations that may occur during high-speed peeling of small-diameter logs, ensuring long-term precision.

Spindleless Main Drive System: A core feature. Consists of multiple sets of precision friction rollers that drive the log rotation through strong friction, eliminating the need to pierce the log ends. This allows for complete peeling from the full log down to a very small core, maximizing utilization.

High-Response Carriage Assembly: Includes a heavy-duty peeling knife, adjustable pressure bar, and a hydraulically or servo-driven feed unit. Optimized knife angles for softwoods and capable of rapid fine-tuning to execute dynamic compensation commands.

Quick Knife Change & Centering Mechanism: Facilitates knife replacement or sharpening, reducing downtime. Integrated automatic centering device ensures the optimal starting position for each irregular log.

(2) Intelligent Control & Sensing System

PLC & Intelligent HMI Control Center: The machine's brain. Pre-loaded with processing parameter models for various plantation wood species. Operators can easily select modes via the touchscreen (e.g., "Eucalyptus - Thin Veneer Mode").

Dynamic Pressure Compensation Module: The core intelligent unit. Collects signals via carriage resistance sensors and spindle load monitors, processed in real-time by the PLC to adjust feed speed, maintaining consistent thickness through knots.

High-Precision Detection Units: Include a feed encoder (controls thickness), laser length measurer (controls cut length), and online thickness gauge (quality monitoring).

Servo Drive System: Provides power for the carriage feed and friction roller drive, offering fast response and precise control, which is fundamental for intelligent compensation and stable peeling.

(3) Auxiliary & Output System

Automatic Cutting & Output System: Includes a pneumatic or hydraulic guillotine and a belt conveyor or roller table for fixed-length cutting and smooth discharge of veneer.

Winding or Stacking Device (Optional): Configurable with an automatic winder or CNC stacker based on veneer thickness and customer needs.

Centralized Lubrication & Dust Removal Interface: Automatically lubricates key moving parts and includes ports for dust extraction pipelines, maintaining a clean work environment suitable for modern workshops.

We are Shandong MINGHUNG Wood Based Panel Machinery Co.,Ltd China factory and manufacturer of full sets of Plywood machinery and Veneer machinery. With many years production experience, advanced production technology,experienced workers and professional engineers, we can offer you the suitable, good and strong machinery for you.

The machinery we produce includes peeling machines, chipping machines, rotary cutting machines, drying machines, gluing mixers, laying machines, pre-pressing machines, hot pressing machines, cooling machines, longitudinal and transverse sawing machines, sanding machines, as well as auxiliary machinery such as automatic feeding and discharging systems and lifting platforms.

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com