- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

- Home

- OSB PB MDF Machine Serise

- OSB/Oriented Strand Board Production Line

- Particleboard/Chipboard Production Line

- MDF/Medium Density Fiberboard Production Line

- Drum Chipper/Crusher

- Flaking Machine

- Rotary Drum Dryer

- Vibrating Screen Machine

- Gluing Machine

- Paving Forming Machine

- Pre Press Machine

- Hot Press Machine without Laminating

- Fast Short Cycle Laminating Hot Press Machine

- Cutting Saw Machine

- Sanding Machine

- Veneer Drying Series

- Veneer Machine Serise

- Plywood Machine Series

- Plywood Pre Pressing

- Hot Press Machine

- Film faced hot press

- Glue Spreader

- Plywood Saw Machine

- Plywood Sanding Machine

- Boiler

- Plywood Paving Machine

- Plywood Machine Accessories

- Frequency Converter

- Air Solenoids Valve

- Contactor

- Conveyor Mat

- Display Screen

- Double Roller For Veneer Peeling

- Encoders

- Feeder Screw

- Glue Granule

- Glue Line

- Ground Roller

- High Pressure Pump

- Hot planten

- Hydraulic Solenoids Valve

- Lower Pressure Pump

- Motor

- Oil Cylinder

- PCL

- Peeling Knife

- Penumatic Cylinder

- Portable Dust Collector

- Pressure Gauge

- Rubber Hose For Hot press

- Rubber Roller For Glue Spreder

- Rubber Roller For Veneer Peeling

- Saw Blade

- Saw Table

- Sensors

- Single Roller For Vneer Peeling

- Speed Reducer

- Stainelss Steel Plante

- Steel Roller For Glue Spreader

- Temperature Control Valve

- Thermo Couple

- Thickness Gauge

- Thin Belt

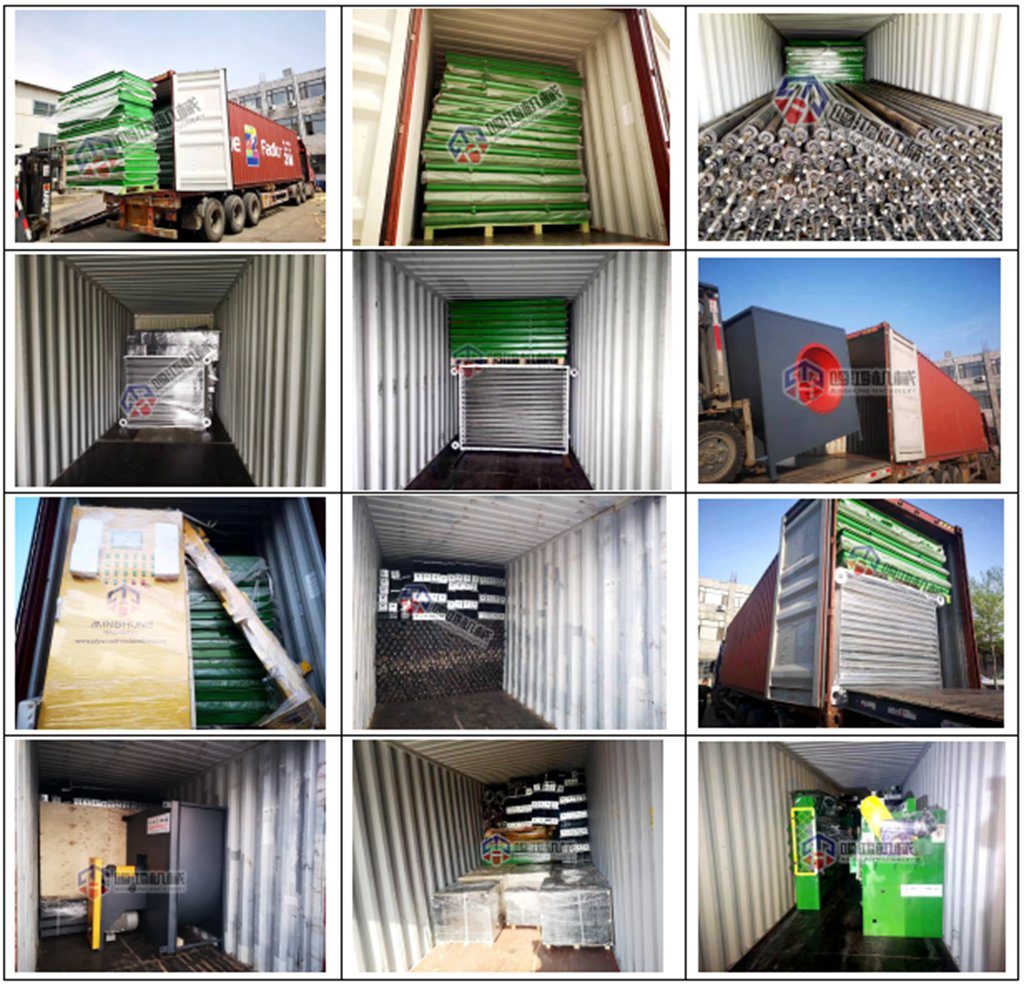

- Turnkey project

- Accessories

- Plywood Auxiliary Machine

- Contact Us

Veneer drying

Veneer drying