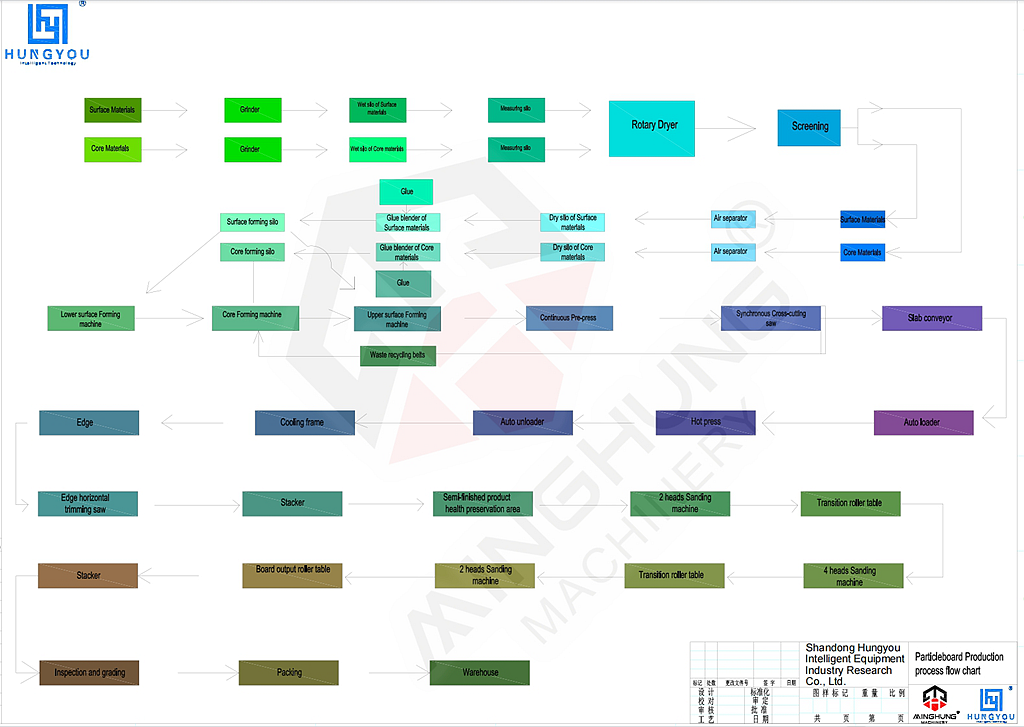

The entire production line is a highly automated system engineering project, which can be divided into four main sections: Raw Material Preparation Section, Forming & Mat Forming Section, Hot Pressing Section (Core), and Post-Press & Finishing Section.

1. Raw Material Preparation Section

The goal of this section is to convert raw wood materials into qualified, glued particles.

Chipper/Flaker: Chips logs, small-diameter wood, or wood processing residues into flakes or particles that meet process requirements.

Screening Machine: Classifies particles by size. Over-sized particles are sent back for re-crushing, while fines can be used for surface layers or other products, ensuring uniformity of the forming material.

Dryer: Typically uses high-efficiency rotary drum dryers to reduce the moisture content of particles from about 30%-50% to a suitable 2%-4%, preparing them for gluing.

Pneumatic Conveying System: Transports dried particles to the next stage via pipelines and fans, and may remove impurities like metal and sand.

Glue Blender: One of the core equipment. Uses high-speed continuous blenders to precisely and uniformly mix particles with adhesives (e.g., UF resin), hardeners, and waterproofing agents (e.g., wax). Its dosing accuracy directly determines glue consumption and product quality.

chipper

vibrating screen

dryer

glue mixer

2. Forming & Mat Forming Section

The goal of this section is to form the glued particles into a mat with uniform thickness and a symmetrical structure.

Forming Station/Forming Machine: Another core equipment. It determines the internal structure of the board. Typically uses mechanical-airform composite forming heads to precisely spread surface-layer fine particles and core-layer coarse particles separately, forming a "fine-coarse-fine" three-layer mat structure. This is key to ensuring the board's mechanical properties (like high strength and good screw-holding capacity).

Mat Pre-Press: The loose mat from the forming station passes through a pre-press for initial compaction. Its main functions are:

To remove air from the mat, preventing blistering during hot pressing.

To increase the mat's initial strength, facilitating transport to the continuous press without breaking.

To reduce mat thickness, decreasing the press opening height and improving efficiency.

mat forming machine

pre press

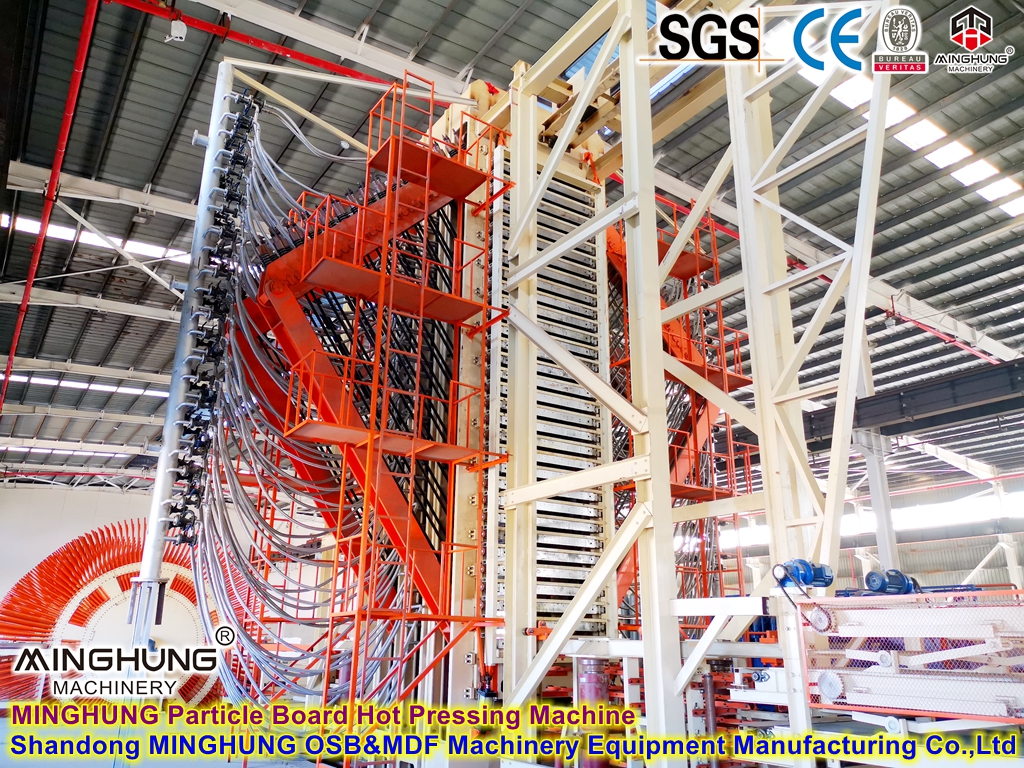

3. Hot Pressing Section - System Core

The Continuous Flat Press is the "heart" of the entire production line. Its technical level directly determines the production line's capacity, energy consumption, and product quality ceiling.

3.1 Working Principle Overview

The continuous flat press uses two massive, endless heat-resistant alloy steel belts to sandwich the pre-pressed mat and carry it through a long, narrow press channel where high temperature and pressure are applied. Inside the channel, the mat is progressively heated, pressurized, and cured as it travels, finally exiting the other end as a fully formed, continuous particleboard.

3.2 Core Components

a. Steel Belt System

Function: Carries and conveys the mat, while uniformly transferring pressure and heat to the mat surface.

Requirements: Extremely high surface finish (determines board surface quality), excellent heat resistance, fatigue strength, and dimensional stability. It is a core wearing part requiring regular maintenance and replacement.

Tensioning & Tracking: Equipped with complex hydraulic tensioning and automatic tracking systems to ensure the steel belts are always under proper tension and do not run off track during operation.

b. Hydraulic System

Function: Provides powerful, stable, and precisely zone-controlled main pressure and pressure profile for the press.

Zone Control: This is the essence of the continuous press. The hundreds of hydraulic cylinders above the press are divided into multiple independent pressure zones (e.g., inlet zone, main press zone, venting zone, stabilizing zone). The system can be programmed to control the pressure in each zone, forming an optimized pressure profile. For example:

Inlet Zone: High pressure for rapidly compacting the loose mat.

Main Press Zone: Maintains high pressure to promote resin flow and penetration.

Venting Zone: Briefly releases pressure to allow steam and air trapped inside the mat to escape.

Stabilizing Zone: Pressure gradually decreases, allowing the mat to complete curing in a largely set state, reducing internal stress.

c. Heating System

Function: Provides the heat required for mat curing, typically sourced from an independent thermal oil heater.

Zone Temperature Control: Similar to the hydraulic system, the heating platens are also divided into multiple independent temperature control zones. An optimized temperature profile can be set, for instance, higher temperature at the inlet to quickly initiate resin curing, and appropriately lower temperature at the outlet to stabilize the board. Temperature control accuracy can reach ±1.5°C.

d. Frame & Roller Carriage System

Function: Forms the skeleton of the press, supporting all the weight and enormous working pressure.

Design: Manufactured from high-strength steel, optimized via Finite Element Analysis (FEA), ensuring minimal deformation under long-term extreme loads. The internal dense array of rollers supports the steel belts, reducing friction and deformation.

e. Control System

Function: The "brain" and "nerve center" of the press.

Capabilities: Deeply integrated with the production line's main control system, it collects and processes thousands of data points in real-time (pressure, temperature, speed, position, motor currents, etc.). It can:

Automatically coordinate the hydraulic, heating, and drive systems according to preset recipes.

Achieve closed-loop thickness control by monitoring the output board thickness and automatically fine-tuning the press inlet opening to ensure thickness tolerance remains stable within ±0.15mm.

Possess advanced diagnostics, fault prediction, and wear life monitoring functions.

4. Post-Press & Finishing Section

The goal of this section is to perform final processing on the continuous board ribbon from the press to create a commercial panel.

Cooler Star: The board exiting the press is very hot (>90°C) and needs forced air cooling in the cooler star to reduce its temperature below 50°C. This process stabilizes the board's internal structure, releases some stress, and prevents warping.

Cross-Cutting and Trimming Saw: Automatically cuts the continuous board ribbon to standard market sizes (e.g., 1220x2440mm, 1830x2750mm) for length and edge trimming.

Stacker: Automatically stacks the cut panels into piles for packaging and shipping.

Sanding Line: Key quality assurance equipment. Calibrates the board surface through sanding, eliminating thickness variation and the pre-cured layer, resulting in a flat, smooth, and dimensionally accurate surface, providing a perfect substrate for subsequent deep processing like laminating or edging.