The production equipment of this production line

I. Core Heat Source System: Thermal Oil Heating System

This is the "heart" of the entire production line, responsible for providing thermal energy.

1. Thermal Oil Heater (Thermal Fluid Heater): The core heating unit, using gas, oil, or biomass as fuel to heat the thermal oil to the set high temperature.

2. High-Temperature Circulation Pump: The "muscle" of the system, providing power to force the hot thermal oil to circulate in the closed piping.

3. Expansion Tank (High-Level Tank): Accommodates the expansion of the thermal oil when heated, stabilizes system pressure, and replenishes oil.

4. Storage Tank (Low-Level Tank): Stores thermal oil drained from the system during maintenance or oil change.

5. Oil-Gas Separator: Removes gases and light components generated in the thermal oil during heating, ensuring stable system operation.

6. Dust Collector/Economizer: Recovers waste heat from flue gas to preheat air or water, further improving system thermal efficiency.

7. Oil Filling Pump: Used to pump new thermal oil into the system.

8. Precision Filtration System: Filters impurities and carbon deposits from the thermal oil, protecting pumps and valves, and extending oil life.

9. Intelligent Control System: PLC control cabinet, temperature, pressure, and flow sensors for fully automatic and precise control of oil temperature, flow, and pressure.

II. Plywood Production Host & Auxiliary Equipment

This is the "body" of the production line, responsible for each process from log to finished product.

1. Log Preparation Section:

Cross-Cut Saw: Cuts logs into required lengths (blocks).

2. Veneer Making Section (Peeling):

Debarker: Removes bark from the logs.

Log Steaming/Soaking Pool: Softens the log blocks for easier peeling.

Veneer Lathe/Peeler: Peels the log block into a continuous veneer sheet.

Veneer Clipper: Cuts the continuous veneer into sheets of specified dimensions.

3. Veneer Drying & Processing Section:

Veneer Dryer: Typically a roller or mesh belt dryer, using waste heat from the thermal oil heater or independent heating to dry the wet veneer to the proper moisture content.

Veneer Splicer: Joins small veneer sheets into full-size sheets.

Veneer Patcher: Repairs defects on the veneer sheets.

4. Gluing & Layup Section:

Glue Spreader: Applies adhesive evenly onto the veneer sheets.

Layup Line/Pre-Press: Assembles the glued veneers with their grains cross-oriented and performs a pre-pressing to form a preliminary mat.

5. Core Hot Pressing Section:

Multi-Opening Hot Press: This is the core equipment where the thermal oil system directly functions. The heating plates inside the press have internal flow channels. Thermal oil flows through these channels, transferring heat to the mat to cure the adhesive under high temperature and pressure. This is the fundamental difference from steam heating.

6. Finishing Section:

Cooling and Turning Machine: Cools and turns the hot-pressed panels to prevent warping.

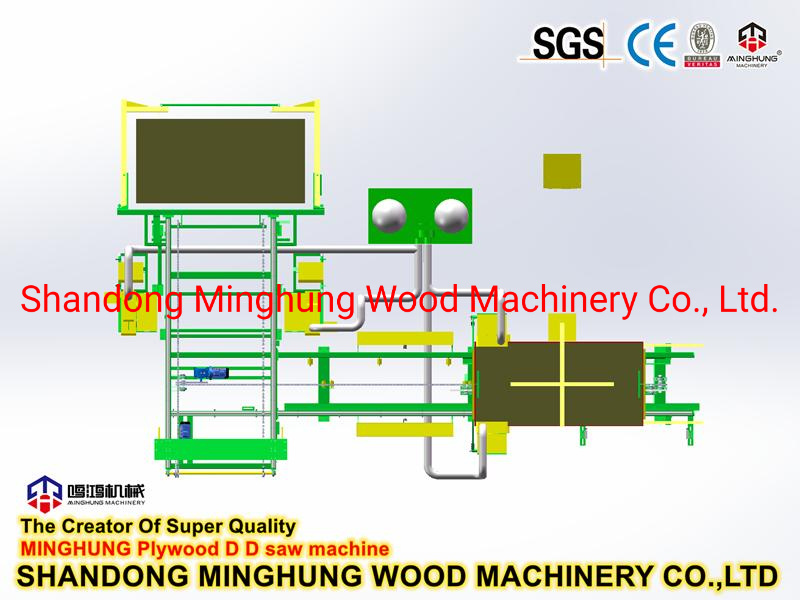

Cross-Cut & Edge Trimming Saws: Trims the rough-edged panels to standard sizes.

Sanding Machine: Sands the panel surfaces to make them smooth, flat, and uniform in thickness.

Inspection & Packaging Table: Grades, inspects, and packages the finished products.

Conclusion: This production line is a complex system engineering project. The thermal oil system is connected via pipes to the heating plates of the hot press, replacing the traditional steam boiler and providing an efficient and stable heat source for the entire production process.