Main equipment composition

A complete high-capacity production line is a complex system engineering project. Its equipment can be divided into the following major systems according to the process flow:

| I. Raw Material Processing & Veneer Preparation Section |

1. Automated Log Handling System

Equipment: Gantry crane/Chain conveyor, Drum debarker, Fixed-length cross-cut saw.

Function: To automate the feeding of logs, remove bark, and saw them into required-length segments.

log debarker

log cutting saw machine

2. Veneer Peeling Production Line

Equipment: Large CNC Spindleless Lathe, Veneer conveyor belt.

Function: To continuously and steadily peel the log segments into continuous veneer ribbons of fixed thickness. The spindleless design is especially suitable for large-diameter logs, offering high peeling efficiency and minimal core loss.

3. Veneer Drying & Processing System

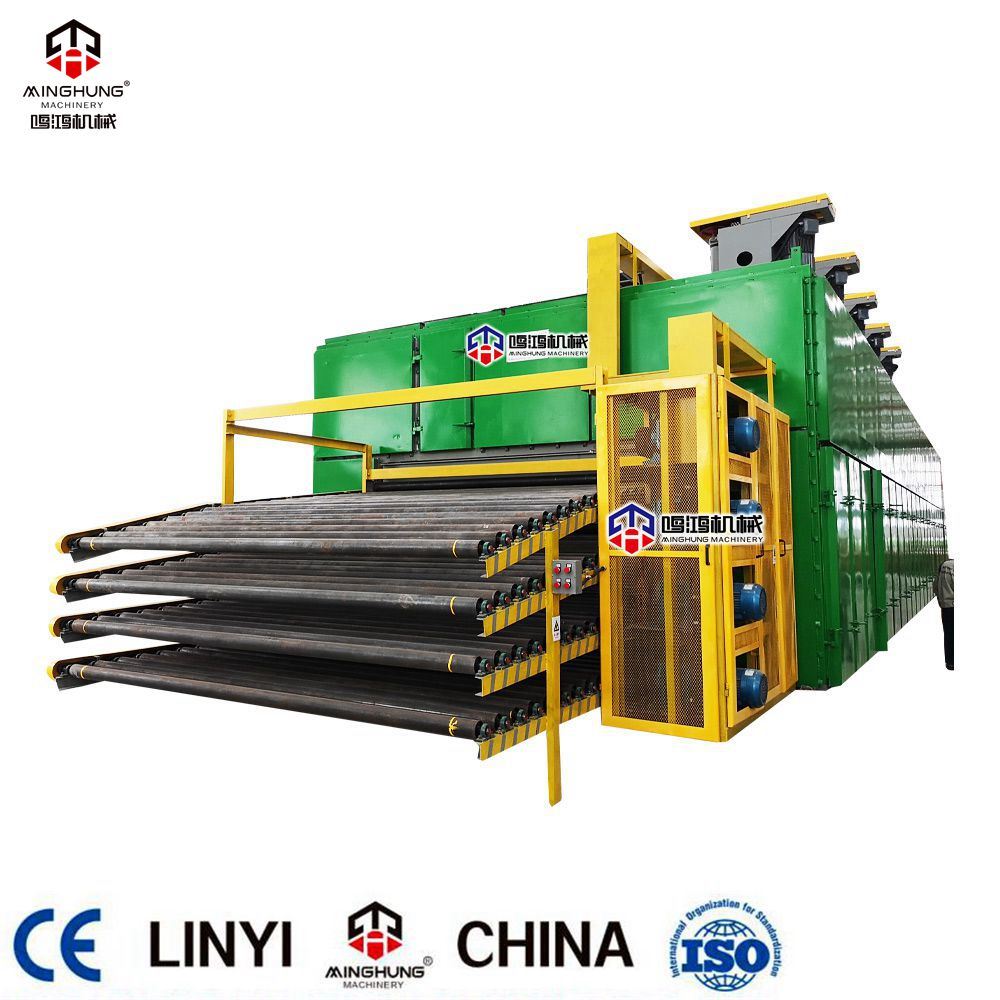

Equipment: Large Mesh Belt Dryer (usually 10+ layers) or Roller Dryer, Veneer Automatic Clipper, Veneer Automatic Stitching/Splicing Machine.

Function:

Dryer: Efficiently reduces the moisture content of wet veneer from over 60% to 8%-12%, which is crucial for ensuring bonding quality.

Clipper: Cuts the veneer ribbon into sheets of set length.

Splicing Machine: Joins small or narrow veneer sheets into full-size sheets, significantly improving raw material utilization.

| II. Glue Mixing, Application & Layup Section |

4. Automatic Glue Mixing & Application System

Equipment: Automatic glue mixing tank, Four-roller Fully Automatic Glue Spreader.

Function: Automatically prepares and supplies adhesive, applying it evenly and quantitatively onto the veneer sheets via precision glue rollers.

glue blender

glue coating machine

5. Fully Automatic Layup System

Equipment: Automatic Layup Production Line (includes veneer manipulators/robots, assembly station, pre-press, panel mat conveyor).

Function: This is the iconic equipment of a high-capacity line. It automatically handles the conveying, assembling, and aligning of face and core veneers to form the "face-core-face-core-face" structure, followed by light pre-pressing to give the mat initial shape for easier loading into the hot press. It completely replaces manual labor, operates at very high speeds, and ensures consistent quality.

| III. Hot Pressing & Finishing Section |

6. Core Equipment: Multi-Opening Hot Press System

The Multi-Opening Hot Press is the "heart" of the entire production line, directly determining the line's output, efficiency, and the core quality of the final product.

| Structure & Working Principle |

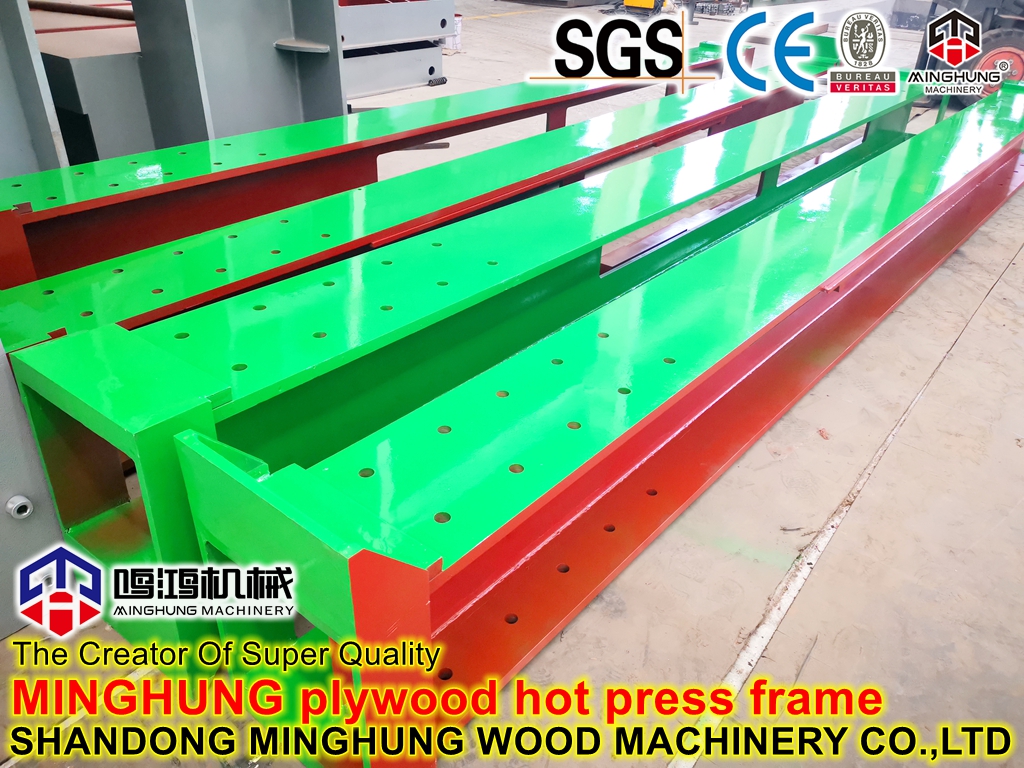

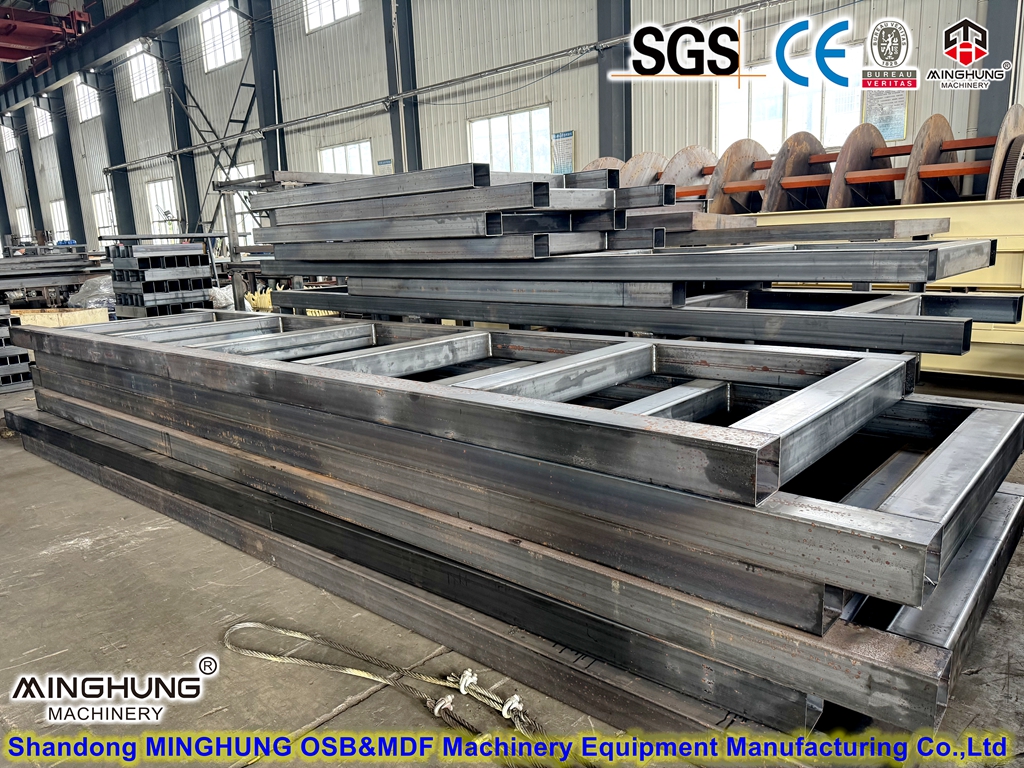

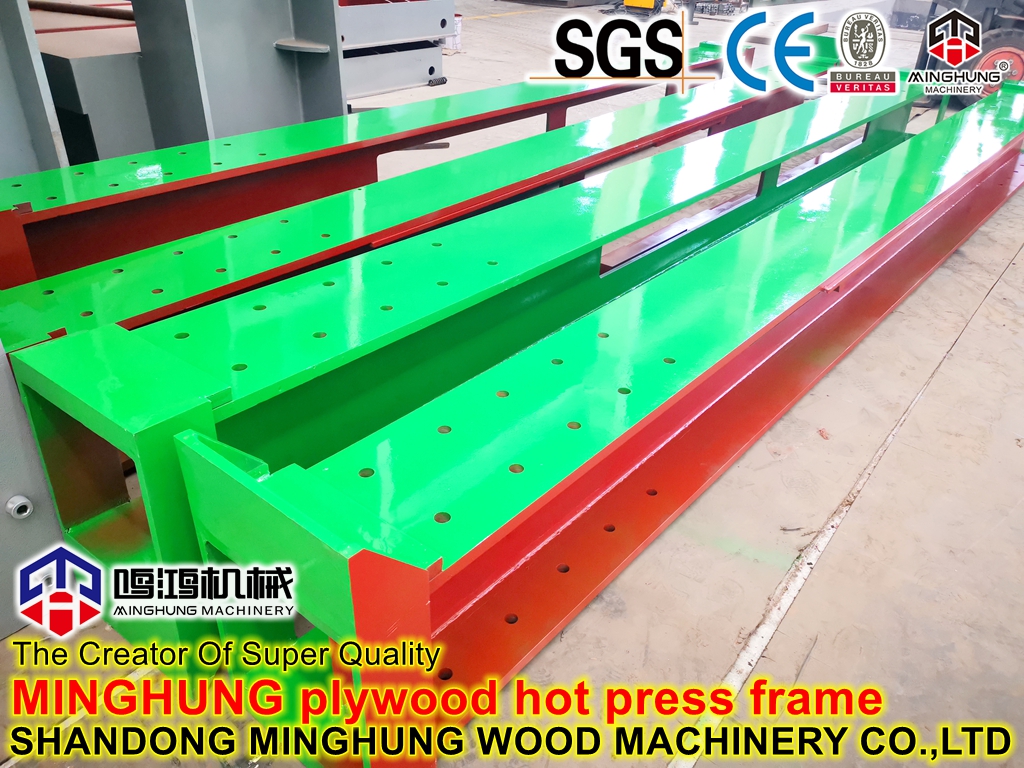

6.1 Main Frame: Composed of Columns and Base made from high-strength steel plates, forming an extremely stable rigid structure to withstand repeated high pressure (typically up to 200-300 tons or even higher).

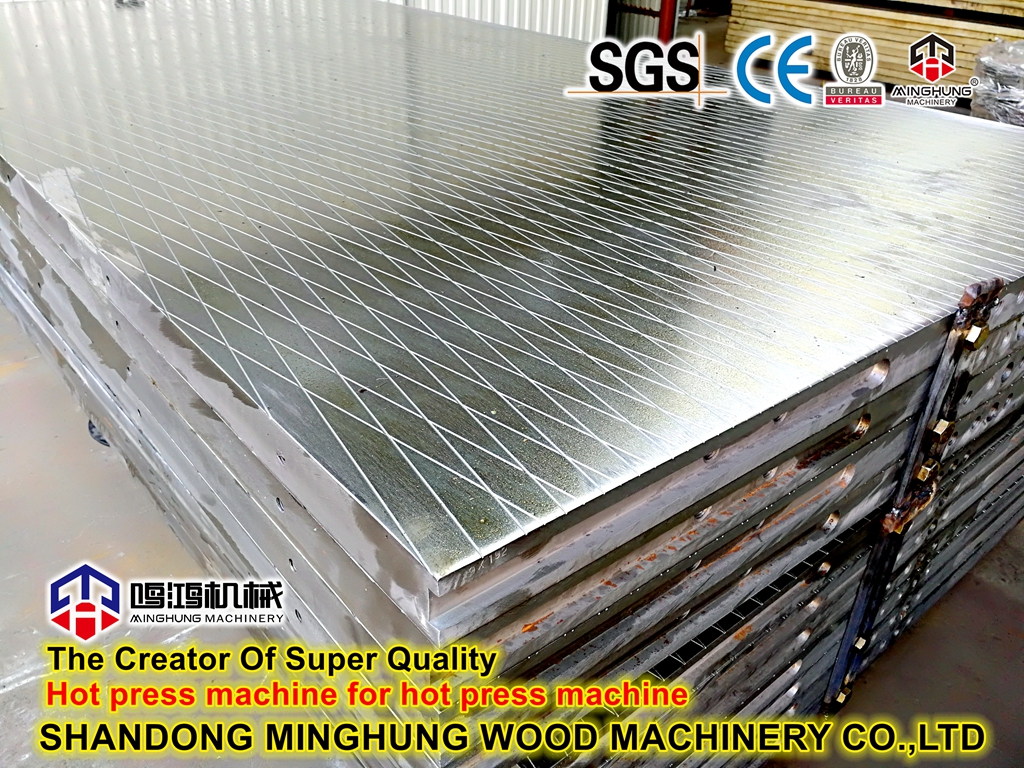

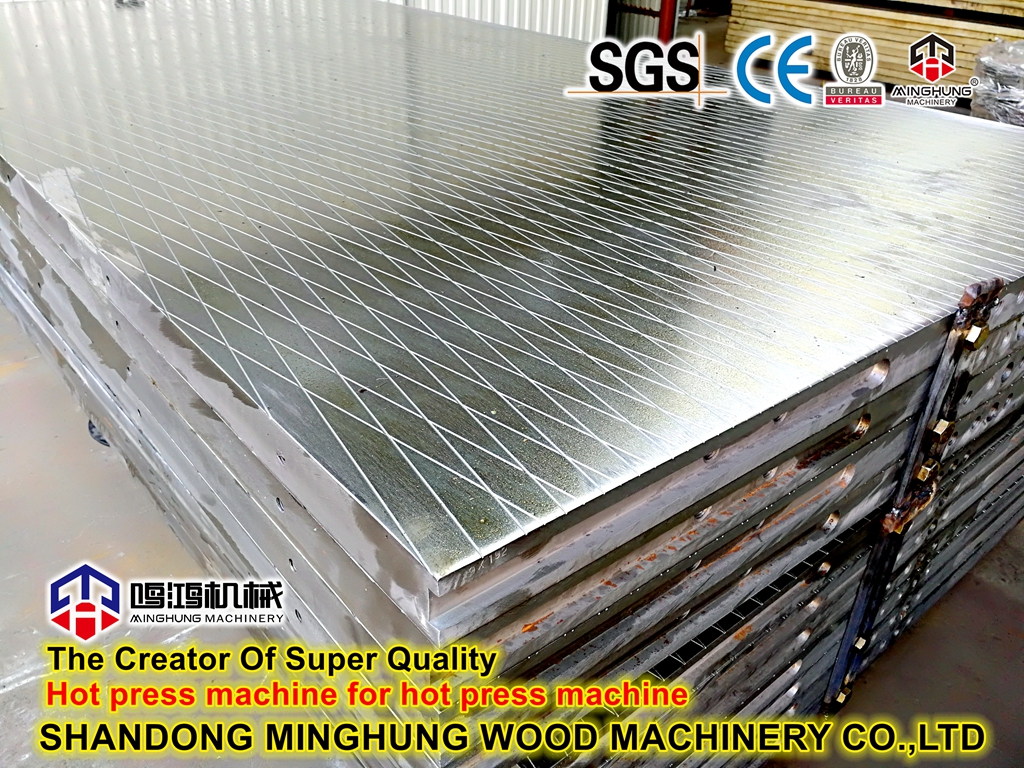

6.2 Hot Plates:

These are the components that directly contact the panel mat, typically made of high-quality alloy steel with complex internal flow channels.

Function: To transfer heat evenly and efficiently to the mat via thermal oil or high-pressure steam circulating internally, causing the adhesive to cure rapidly at high temperature.

Surface Requirements: Extremely high flatness, smoothness, and hardness to ensure the pressed panels have a flat surface and prevent sticking.

6.3 Hydraulic System:

This is the power source providing the pressure, including Main Cylinders, Oil Pumps, Motors, Control Valve Blocks, and Accumulators, etc.

Workflow: The system drives the cylinder piston to rise, pushing the moving platen to close and apply massive, uniform pressure to the mat.

Characteristics: The hydraulic system of a high-capacity hot press must be responsive, maintain stable pressure, and achieve precise control for multi-stage pressing (e.g., Fast Closing → Low-Pressure Closing → Pressure Build-up → Pressure Holding → Pressure Relief).

6.4 Heating System:

A Thermal Oil Heater System is the most common and efficient choice. The thermal oil is heated in the heater and circulated through the hot plates via pumps, providing stable, uniform heat.

The system is equipped with precise Temperature Control Devices to ensure consistent temperature across every hot plate, with minimal temperature variation (e.g., ±2°C).

6.5 Control System:

Modern high-capacity hot presses use an automatic control system based on PLC (Programmable Logic Controller) + Touch Screen HMI.

Functions:

Set & Store Process Parameters: Allows pre-setting the three core parameters - Temperature, Pressure, Time - for different product specifications.

Fully Automatic Control: Automatically executes the entire pressing cycle without manual intervention.

Fault Diagnosis & Alarm: Monitors equipment status in real-time, immediately alarms and indicates the fault point upon abnormality.

Data Logging: Records data for each pressing cycle, facilitating quality traceability and production management.

| Key Characteristics in High-Capacity Production Lines |

High Number of Openings & Large Daylight: The number of openings determines the quantity of mats pressed per cycle. High-capacity lines are typically equipped with hot presses having 20, 30, 40 openings or more.

Simultaneously, the height of each opening (daylight) is also larger to accommodate the production of panels of different thicknesses.

Fast Closing & Pressure Relief:

To shorten the cycle time per press, high-capacity hot presses use Rapid Advance Cylinders or Accumulator Assistance to achieve rapid upward and downward movement of the moving platen.

Simultaneous Closing Mechanism:

This is a standard feature in mid-to-high-end hot presses. It ensures that mats in all openings begin to be pressed and contact the hot plates at the exact same moment, guaranteeing that every single panel receives identical heating and pressing time, resulting in uniform and stable product quality.

Excellent Thermal Efficiency & Uniformity:

Optimized thermal oil flow path design and precise temperature control systems ensure highly uniform surface temperature across the hot plates, avoiding defects like poor bonding, warping, or blistering caused by temperature differences.