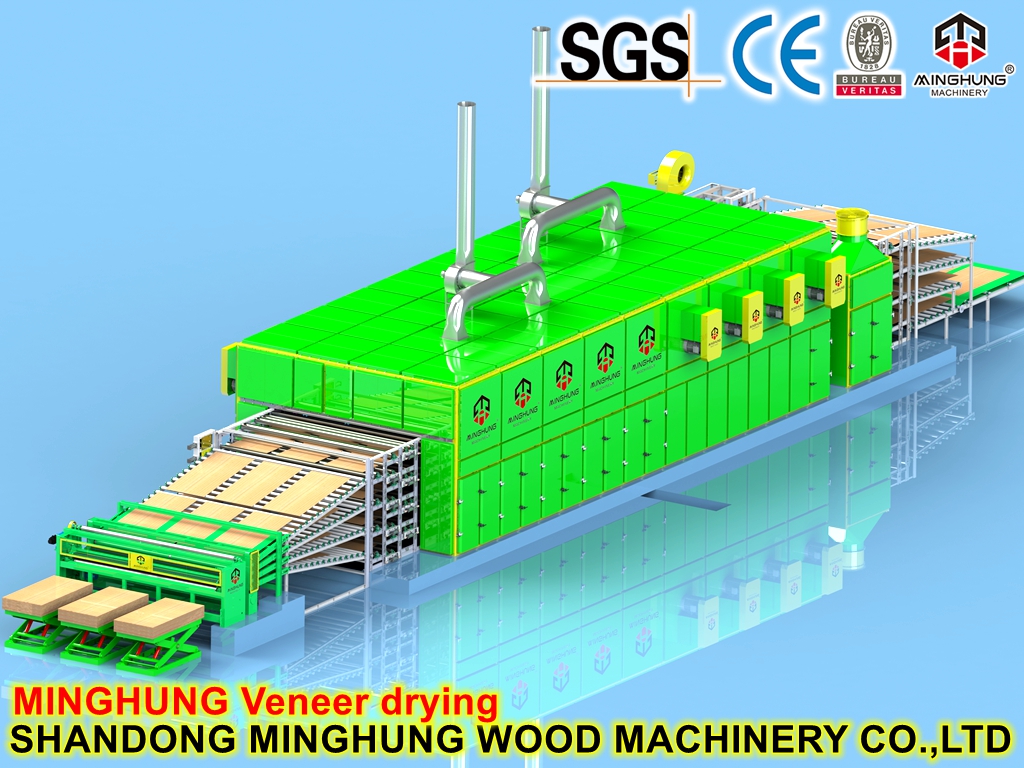

The working principle can be summarized as a "controlled convective hot air drying" process conducted within an exceptionally robust chamber. The entire process relies on the stable, airtight environment provided by the heavy-duty structure to ensure precise execution of the drying schedule.

Step-by-Step Workflow:

1. Loading & Sealing

Wet, freshly pressed plywood sheets are stacked with stickers onto heavy-duty kiln trucks.

The loaded trucks are pushed into the drying chamber along reinforced tracks via forklift or tow tractor.

The reinforced, sealed door is closed and locked, forming a completely enclosed drying space.

2. System Start-up & Warming

The operator selects or inputs a drying schedule matched to the plywood wood species via the intelligent control system.

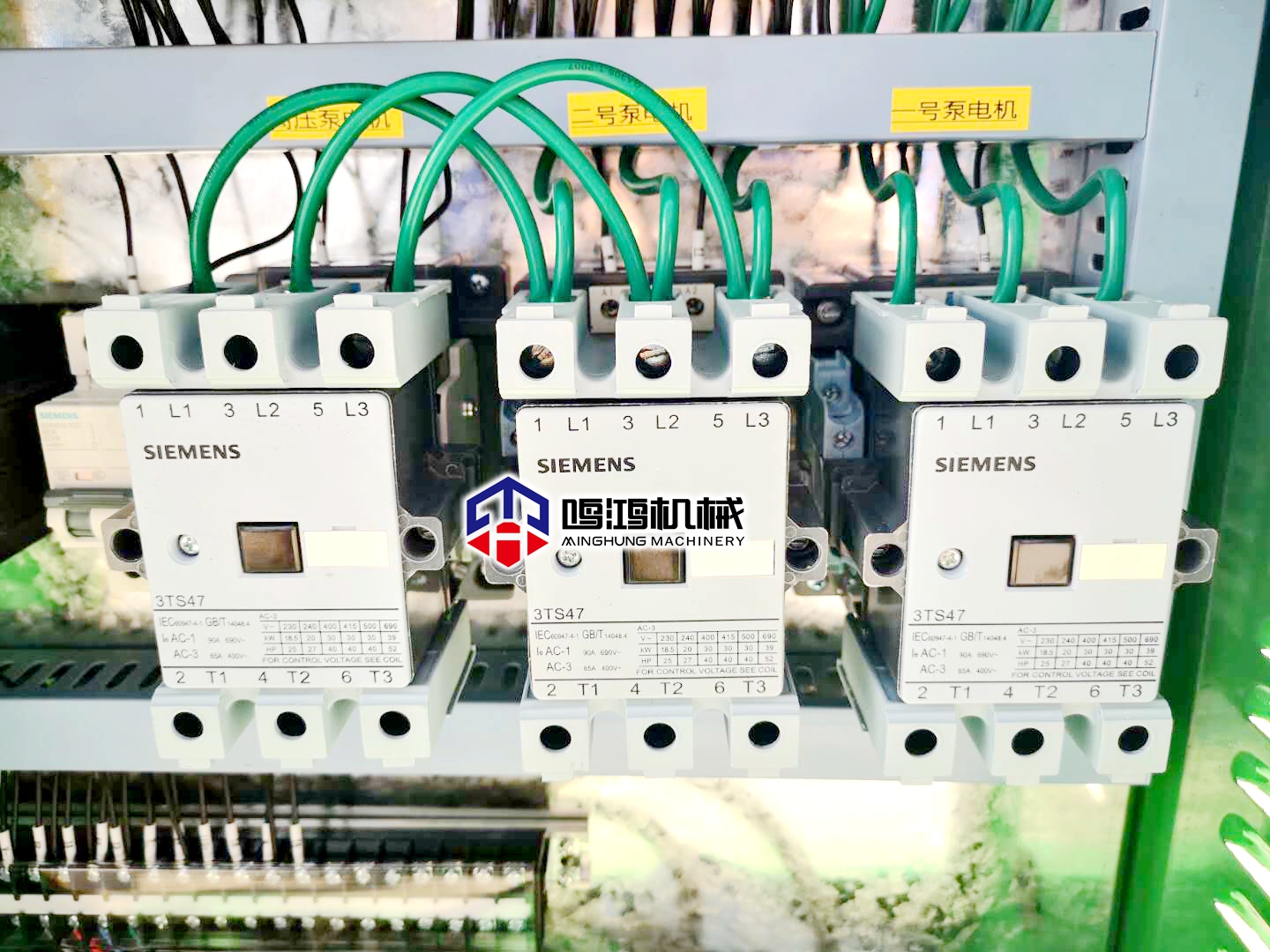

The system starts: the heating unit (e.g., steam heat exchanger, gas air heater) activates, and the circulation fans start simultaneously.

Initially, low temperature and high humidity are used to warm the boards slowly, allowing heat to penetrate from the surface to the core, preventing surface checking from rapid moisture loss.

3. Main Drying Stage (Forced Convection & Dehumidification)

Hot Air Circulation: High-power centrifugal fans forcefully draw heated air from the pressure-equalizing air ducts on one side (or bottom) of the chamber and, via guide plates, distribute it evenly and horizontally through the entire stack. The hot air flows over every plywood sheet, transferring heat via convection and carrying away evaporated moisture.

Intelligent Dehumidification: Humidity sensors installed in the return air duct monitor the chamber's air humidity in real-time. When humidity exceeds the set value, the dehumidification system automatically activates, exhausting a portion of the hot, humid air while simultaneously introducing an equal volume of fresh, dry air. This process is dynamic and continuous, maintaining a powerful drying drive.

4. Conditioning (Stress Balancing)

This is key to ensuring high-quality output from heavy-duty equipment. At critical stages of drying (e.g., near the fiber saturation point), the system activates the steam injection or atomizing humidification system to briefly increase chamber humidity.

This "steaming" process allows the board surfaces to re-absorb some moisture, balancing the moisture gradient between the core and surface, and between areas of different wood densities, effectively releasing drying stress and minimizing deformation and cracking.

5. Cooling & Unloading

After the drying program ends, heating and humidification stop. The circulation fans continue to operate, introducing ambient air to cool the boards slowly and uniformly.

Once the board temperature drops to a safe range (typically 10-20°C above ambient temperature), the fans stop, the door is opened, and the trucks are pulled out, completing the drying cycle.

In Summary: The principle involves using an intelligent system to precisely control hot air, humidity, and time within an indestructible "fortress," achieving uniform, efficient, and gentle drying of plywood.