Double Sides Calibration Machine for Plywood Machine

Dear friend, for save your precious time, please directly send message to me about your requires, i will offer you the suitable machine details.

-------Lucinda/Sales Manager

The Instruction of Sanding Machine: Sanding machine is the last step for producing plywood, for make plywood thickness more accurate and balance, surface more smooth and bright, we have different types, for example, there has 1 head, 2 heads, 3 heads, single side, double sides, light weight and heavy duty, some wants calibrating the thickness very accurate, some wants keep the surface very smooth, so we will offer you the most suitable sanding machine. This is Double sides calibrating machine:

Max Sanding board width | 40-1300mm | 40-1300mm |

Sanding board thickness | 5-150mm | 5-150mm |

Sanding board length | >500mm | >700mm |

Abrasive belt speed | 25m/min | 25m/min |

Abrasive belt size | 1350*2800mm | 1350*2800mm |

Voltage | 380v | 380v |

Frequency | 50hz | 50hz |

Main motors power | 75kw; 75kw | 75kw; 75kw |

Convey feeding motor power | 11kw | 11kw |

Feeding speed | 10-30m/min | 10-30m/min |

Lifting motor | 0.75kw | 0.75kw |

Brushing motor | 0.75kw | 0.75kw*2 |

Total power | 162.49kw | 163.25kw |

Working pressure of compress air | 0.6mpa | 0.6mpa |

The capacity of dust collection | 24000m³/h | 24000m³/h |

size | 2100*3100*3050mm | 2200*3100*3050mm |

Weight | 10000kg | 14500kg |

Note: if your plywood size is special, like the width is 1500mm, 1700mm or more, please tell me, we can customize sanding machine.  ADVANTAGES: <1> For keeping thickness very accurate, require the manufacturing technique very high, and through many years development, our professinal worker and technology can make sure our calibrating machine very accurate.

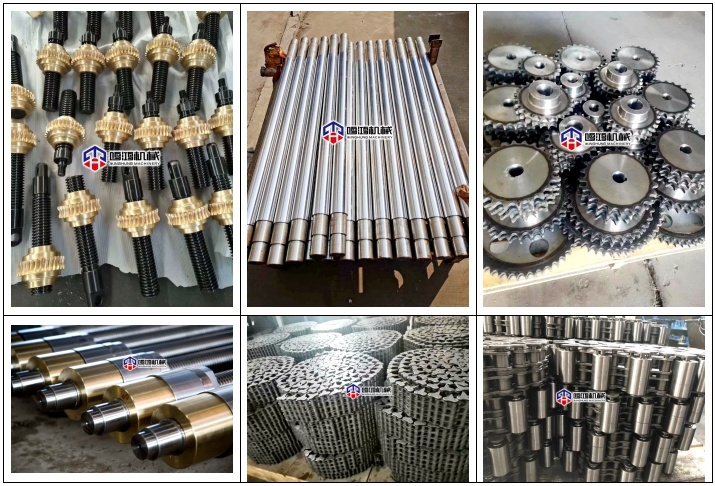

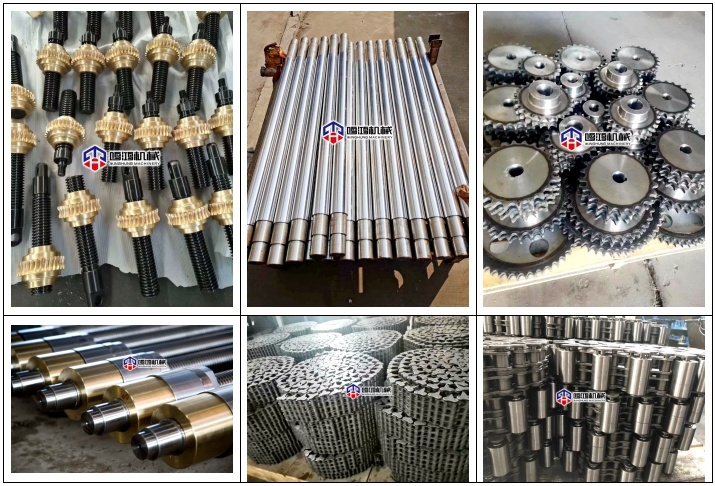

ADVANTAGES: <1> For keeping thickness very accurate, require the manufacturing technique very high, and through many years development, our professinal worker and technology can make sure our calibrating machine very accurate.

<2> The diameter of Steel rod and rubber roller are standard and big, make sure its strong.

<3> The speed of sanding machine is fast, improve production capacity.

<4> Machine has device for collect the dust, keep clean.

<5> There has buttons for your operation, easy and convenient.

<6> The electric components use Schneider brand. FACTORY:

>Machine we produce:

wood debarker, veneer peeling machine, veneer stacker, knife grinder, veneer dryer machine, glue spreader,

plywood veneer lay-out machine, core composer, plywood cold press machine, plywood hot press machine,

plywood DD saw, sanding machine, lift table.

>Principle:

through many years improvment and development, we have had our own company value, that is offer good and suitable plywood machine to every our client forever, and help their business create much value.

Because we know this, so we insist make our machine well, from the beginning, choose machine material and spare parts, our experienced purchasing manager choose the better one through company different, then our designer will discuss and design machine, then our professional workers will start produce machine, each production step will be responsible by different workers.

the whole production line will be tested at least 5 times to make sure our machine in good conditions.

>Certification:

All our plywood machine have CE, and test report. FACTORY EXISTING SPARE PARTS:

whatever our sanding machine, or other plywood machinery, we all choose the good one, and after our designer finish the drawings, our workers will seriously and responsible treat each production step, different production steps will be responsible by different professional and experienced workers, make sure our machine quality is very good and stable. CLIENTS:

With our clients, we are not just partners, we are friends.

So, we will always think of the problem standing on your position, think how to help you save cost and create benefits.

We welcome you come to visit our factory and check machine by yourself, and produce machine according to your needs. DELIVERY:

Before loading, we will test machine and send you videos.

When loading, we will share loading pictures with you.

After ship leave, we will offer container and ship information to you, and prepare all documents for your custom clearance.

RELATED MACHINE:

RFQ:

> Production Time:

1 month after receive your deposit.

>Payment terms:

30% deposit, 70% before delivery.

100% L/C.

>Warranty:

2 years for main parts.

>MOQ:

1set

> Installation:

when machine reach your factory, our engineer go to install.

> After-sales service:

Any problem that your worker can not solve, we will reply you at the first time, help you solve it.

CONTACTS: