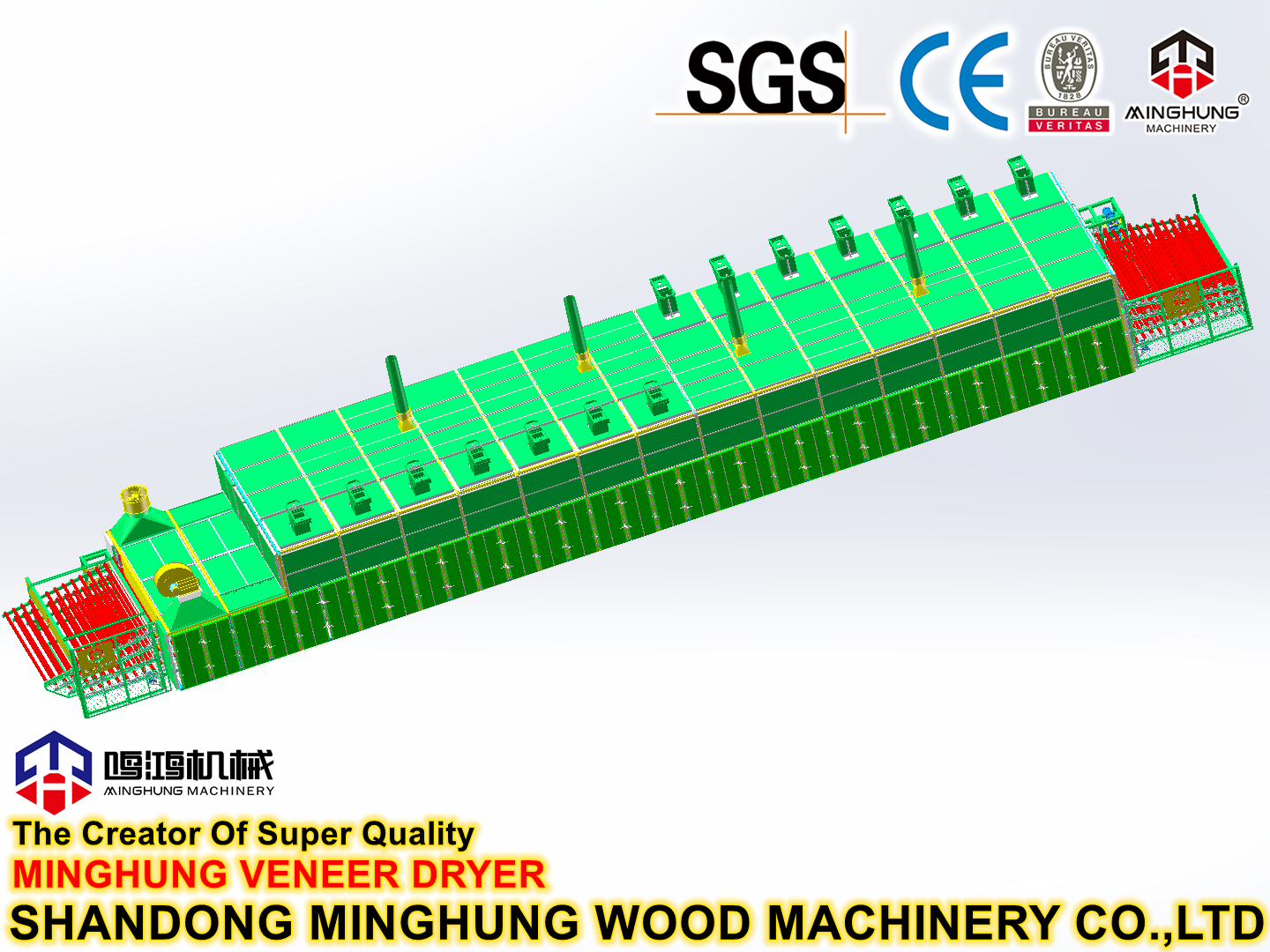

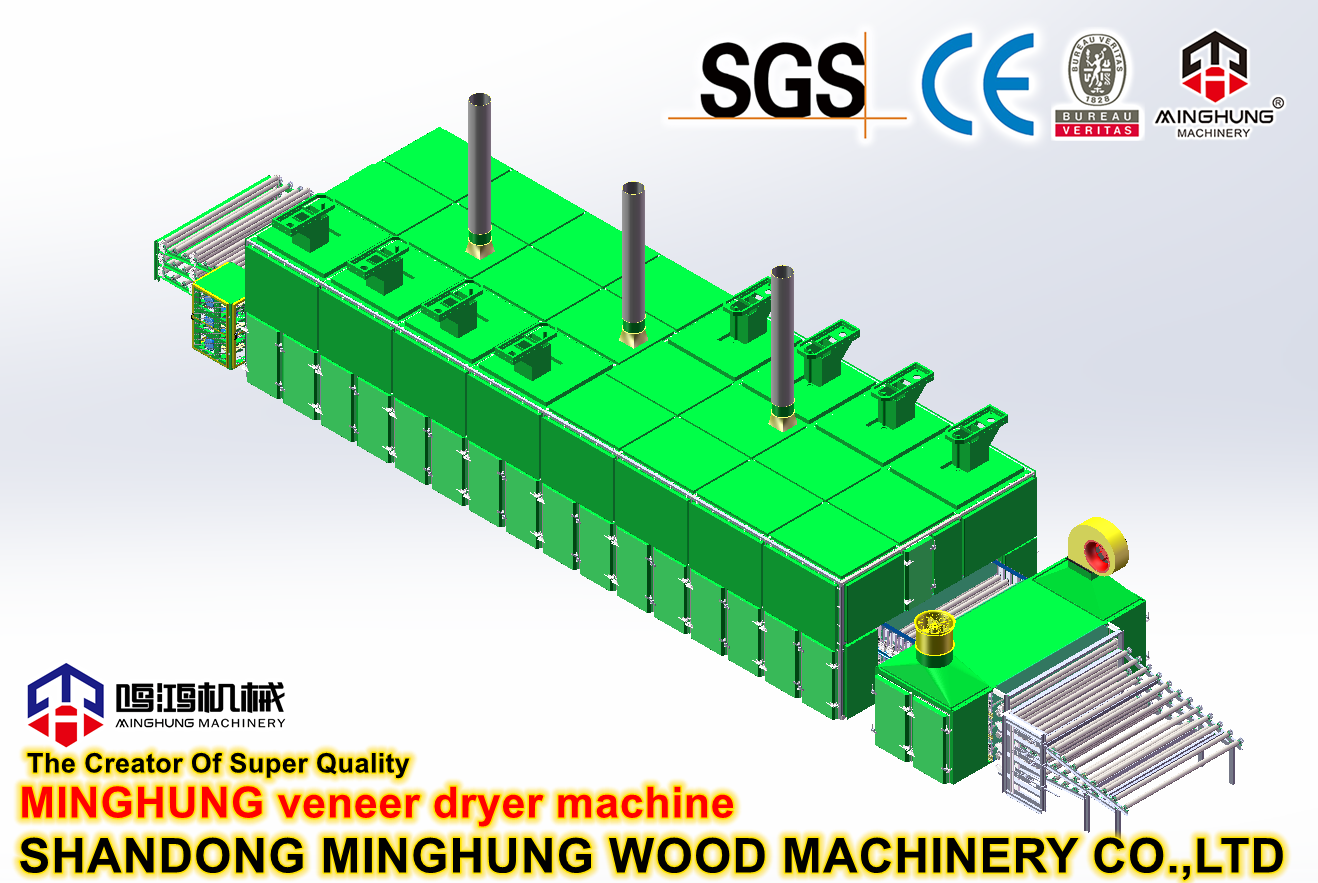

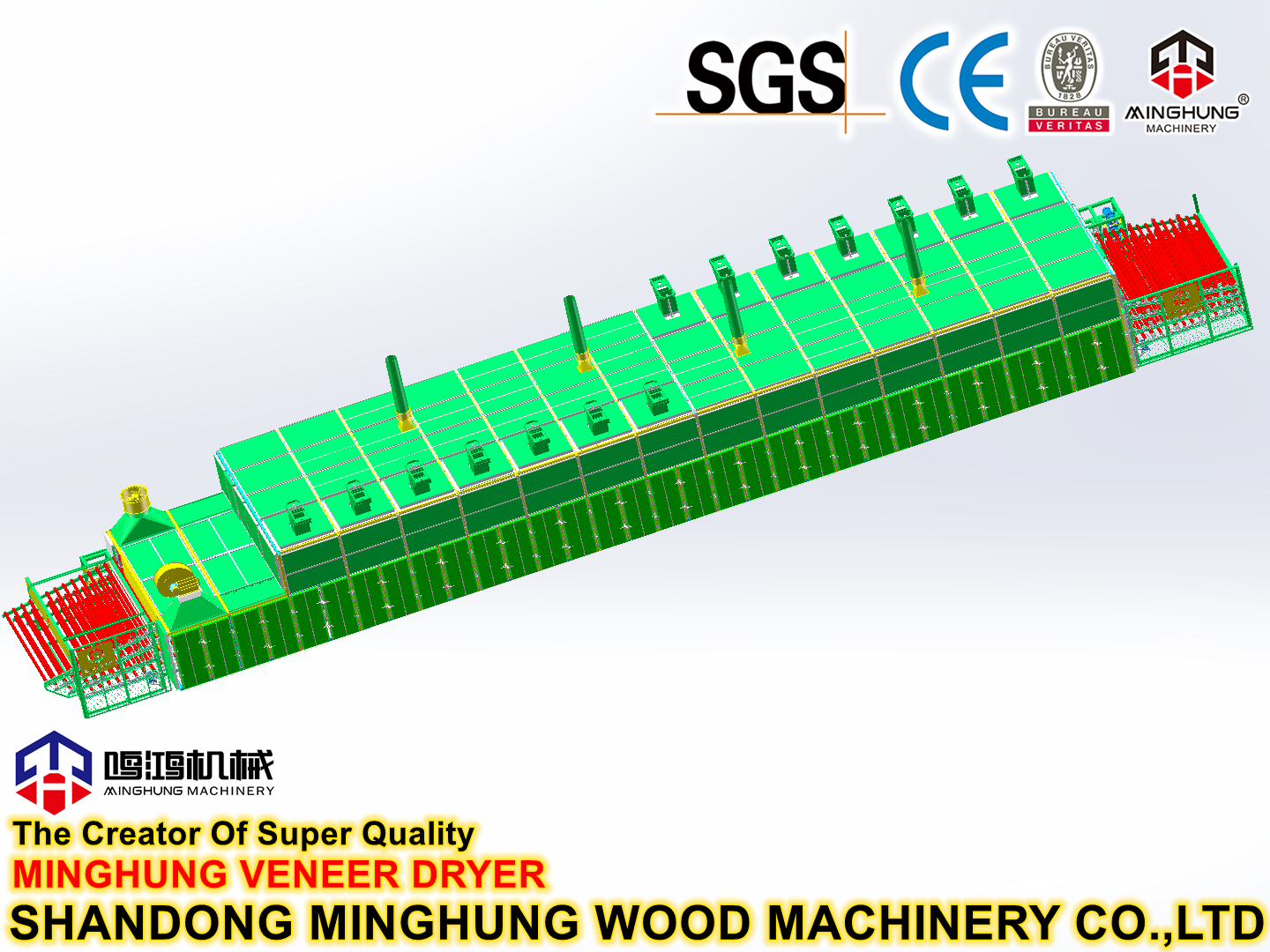

Dryer Machine-Veneer Roller Dryer

MINGHUNG Veneer dryer

The veneer (plywood) dryer can be divided into three heating forms: hot air heating, steam heating, and heat transfer oil heating according to different heating forms. According to different fuels, it can be divided into fuel oil, gas, coal, firewood, and electricity. The equipment can be divided into manual loading and automatic loading. The veneer enters the dryer, and according to the set value, the temperature and humidity in the dryer are automatically controlled, so that the drying material can be leveled and the moisture can be controlled uniformly. The equipment can determine the size of the equipment according to the user's output, and it can be divided into automatic board and manual board. This equipment has large output, high degree of automation, low cost of use, uniform drying, and good effect. Through drying, it can avoid mildew and blue change of plates in high temperature and high humidity environment (such as eucalyptus wood, rubber wood, poplar, camphor It is ideal in the field of veneer processing, flame retardant veneer production, plywood production, flame retardant plywood production, and dyed veneer (board) production. Veneer drying equipment.

product description

Product advantages: This equipment has a high degree of automation, low operating cost, small footprint, and can be operated 24 hours a day, saving labor, and the annual labor cost saving can reach 150,000 US dollars.

Obvious features:

1. High degree of automation, automatic loading, labor saving, automatic heating, dehumidification, high drying intensity, long drying time, high moisture saturation, and energy saving.

2. Dry evenly. The peeled veneer undergoes heat exchange and moisture removal in multiple sections, and after drying for about 1.5 hours, the moisture content is low and uniform, which can meet the production needs of veneer and plywood.

3. The output is large. According to the needs of different users and different materials, the output of the equipment can reach 1---5 cubic meters/H.

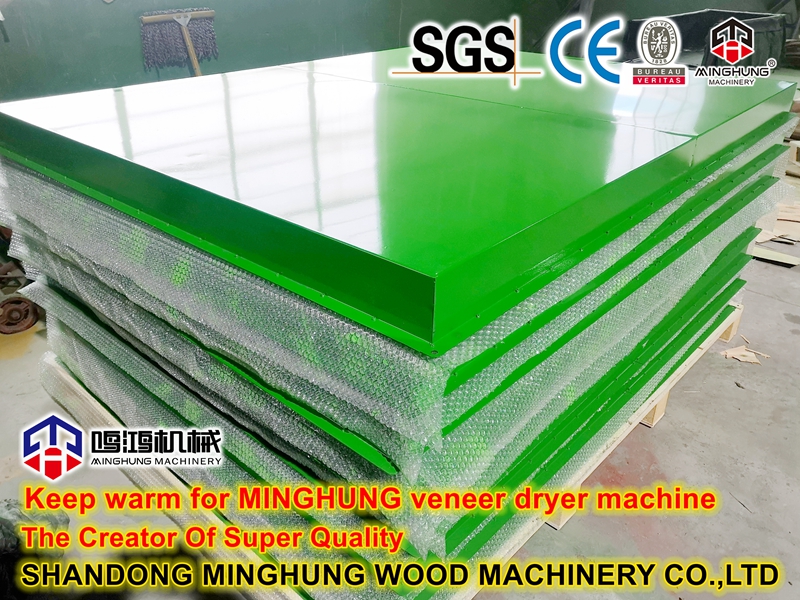

4. The equipment adopts fin-type heating device, which has large heat exchange area, fast temperature increase, large circulating air volume, many cycles, high heat exchange efficiency, high exhaust water saturation, energy saving, and low use cost, which is better than roller type veneer. The drying equipment saves energy by more than 40% (the roller adopts the air spray method, the contact time between the hot air and the plate is short, and the heat exchange efficiency is low).

5. A piece of equipment investment can be used for more than ten years, super cost-effective

6. The failure rate is low, the network belt is worn, and the network is disconnected, and the failure rate of the pallet is low.

7. The equipment adopts vertical plate loading and drying. The operation time of the plate skin in the equipment is long, which can reach 1-2 hours. The temperature can be controlled according to the section. 13----15min, the folding type veneer dryer has large output, low energy consumption and low drying cost.

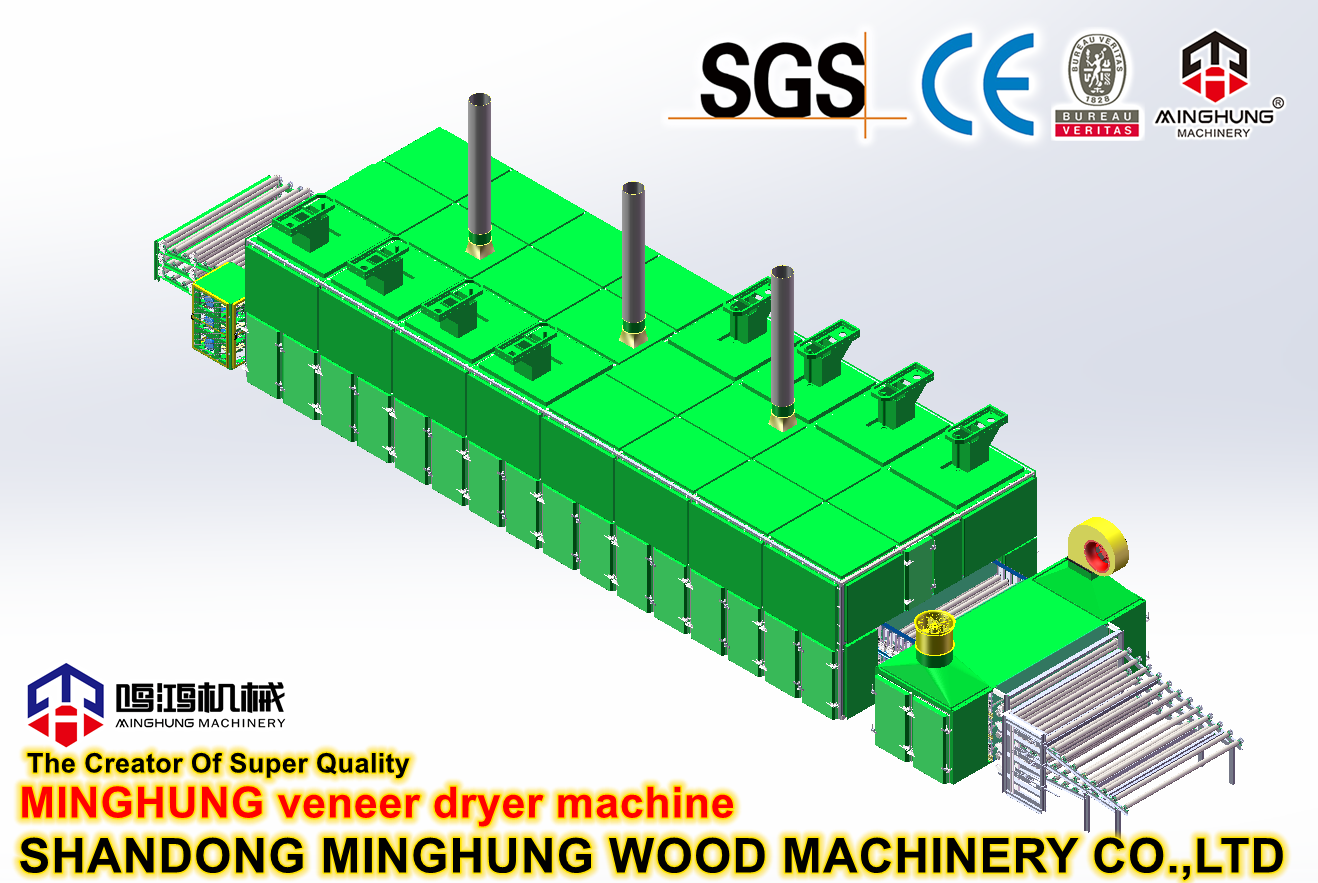

>>>Parameters:

The dryer machine-Roller dryer, can be different layers, length and width, so we usually offer and produce according to your production capacity required.

0

0

|

| Name | Roller dryer |

| Model | MH-RD2830L |

| Heating mode | Steam/Oil |

| Veneer thickness | 1-3mm |

| Transport mode | Roller press mode |

| Speed | Speed adjustable |

| Number of layers | 2 layers/3layers/4layers |

| Length of hot wind area | 20m/26m/30m |

| Peoduction capacity | 10-20m³/day, 20-30m³/day, more |

>>>Main Parts:

>>>Details:

0With our clients, we not just partners, we are friends.

0With our clients, we not just partners, we are friends.

We will stand your position think about problem, consider how to save cost for you, and offer the better and suitable plywood machine to you.

>>>Delivery:

When loading, we will share loading pictures to you.

After ship leave, we will offer you container and ship information.

Offer all documents for you do custom clearance.

>>>Factory:

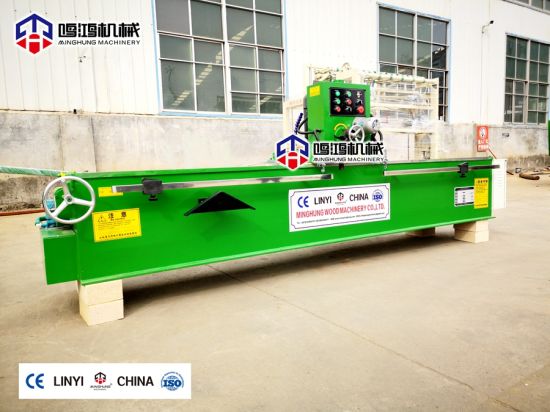

Shandong MINGHUNG Wood Machinery Co.,Ltd is one famous manufacturer of plywood machine in China, located in Linyi city. Our products have acquired EU CE, ISO 9001, ISO 14001, CCEP, and Energy Conservation Certification.

Our company integrates design, research and development, production and sales, and works closely with China's advanced scientific research institutions. We have a strong research and development team, at present, our machinery has won a number of national patents.

Pay more attention to machine details, details determine sucess or failure, so we continuous improve and optimize machines' performance, strictly control each production step, using advanced lathe processing machine, and through many times inspections, make sure our machine accurate and durable.

Scientific and technological innovation oriented, quality-based, service supremacy, we offer full complete range of plywood production solution and technology support for our customers. Yet our machines have been exported more than 30 countries and regions like Russia, Poland, Ukraine, Portugal, Bulgaria, Romania, Turkey, Egypt, Morocco, Indonesia, etc, and get good feedback.

Our main products include wood log debarker, veneer peeling machine, vacuum veneer stacker, veneer dryer machine, plywood cold press machine, plywood hot press machine, glue spreader, glue mixing machine, automatic plywood veneer paving line, sanding machine.

With high efficiency sales team offer 24 hours online service, the professional technical team and after-sales service team offer plant layout, machine drawings, and after-sales service.

Choose us, you need not worry anything, we will help you arrange all.

we will offer you the better and suitable machine, two years warranty, professional technical team at your service anytime. and hope that build a good and long-time cooperation.

>>>RFQ:

| Production Time: |

| 1 month after receive your deposit. |

| Payment Terms: |

30% deposit, 70% before delivery.

100% Letter of Credit. |

| Warranty: |

| 2 years for main parts. |

| MOQ: |

| 1 set |

| Installation: |

| When machine reach your factory, our engineer can go to install |

| After-sales service: |

| Any problem that your worker can not solve, tell us, we will reply you at the first time, |

>>> Contacts:

WHATSAPP: MARK: +8618769900191 ALI: +86155589105786 LUCINDA: +8615805493072

EMAIL: minghungmachinery@gmail.com

0

0

0With our clients, we not just partners, we are friends.

0With our clients, we not just partners, we are friends.