III. 1000m³/Day Equipment

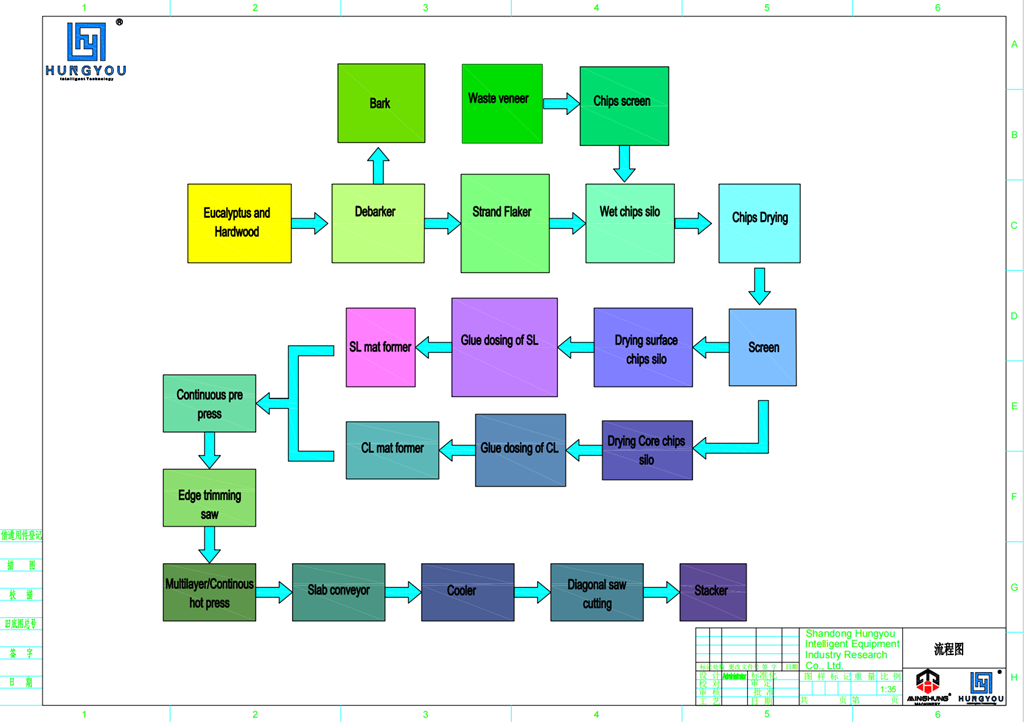

1. Raw Material Processing

Ring Debarker

Performance: Debarking rate ≥99%, log diameter 30-300mm

Components:

▸ Hydraulic rotary cutter (2×132kW)

▸ Wear-resistant alloy blades (HRC58-62)

▸ Auto pressure compensation system

Capacity: 25t/h per unit

Disc Flaker

Performance: Qualified strand rate ≥90% (L:80-120mm, T:0.4-0.7mm)

Components:

▸ Ø1200mm hardened disc (280rpm)

▸ Hydraulic feed system (120kN thrust)

▸ Sieve modules (φ8/12/16mm screens)

Feature: Quick-change blade mechanism (≤15min/tool)

2. Drying & Screening

Triple-Pass Rotary Dryer

Performance: 10t/h water evaporation, final MC 3±0.5%

Components:

▸ 304 stainless steel drum (Ø3.2m×24m)

▸ Biomass burner (≥3500kcal/kg)

▸ Cyclone + wet scrubber (dust ≤30mg/Nm³)

Control: Inlet/outlet sensors linked with dampers (±2℃)

Multi-Deck Sifter

Performance: Fines removal ≥95%, throughput 35t/h

Components:

▸ 3-layer polyurethane screens (mesh 4/8/12mm)

▸ Dual vibration motors (2×18.5kN force)

▸ VFD speed control (amplitude 3-8mm)

3. Blending & Forming

High-Pressure Resin System

Performance: Glue dosage accuracy ±0.3%, MDI utilization ≥98%

Components:

▸ Dual-component tank (with thermal jacket)

▸ Air-assisted nozzles (50-80μm droplet size)

▸ Online viscometer (real-time dilution control)

4-Head Planetary Aligner

Performance: Forming speed 100㎡/min, orientation 0-90° adjustable

Components:

▸ Planetary spreader rolls (4 independent VFD drives)

▸ Laser density scanner (1mm resolution)

▸ Hydraulic scraper adjustment (<10s response)

4. Hot Pressing

8-Opening Continuous Press

Performance: Speed 3-15m/min, pressure 0-6MPa stepless

Components:

▸ 32 hydraulic zones (375kN/cylinder)

▸ High-temp steel belt (1.8mm thick, 1200N/mm² tensile)

▸ 12-zone thermal oil heating (150kW/zone)

Core Tech:

▸ Belt auto-tracking (±0.5mm accuracy)

▸ Gap laser monitoring (100Hz sampling)

5. Finishing Section

Quad-Edge Trimming Saw

Performance: 15s/cut cycle, length error ≤0.3mm

Components:

▸ Carbide-tipped saw blades (Ø650mm, 72T)

▸ Servo positioning rail (±0.05mm repeatability)

▸ Dust collection system (≥99% efficiency)

8-Head Sanding Line

Performance: Sanding depth 0.1-2.0mm, surface Ra≤5μm

Components:

▸ 4 coarse sanding rolls (40-80 grit)

▸ 4 fine sanding belts (120-240 grit)

▸ Contact thickness gauge (±0.01mm precision)

IV. On-line Thickness Adjustment

✅ Real-time Control Solutions:

1. Forming Height Control: Hydraulic adjustment of aligner scraper (9-22mm range, response <3min)

2. Press Synchronization:

Automatic gap calibration (servo motor precision 0.01mm)

Pressure profile auto-optimization (e.g. 4.5MPa for 22mm vs 2.8MPa for 9mm)

3. Sanding Compensation: Auto-grinding based on thickness gauge (±0.3mm tolerance correction)

V. Customization Capabilities

Dimension | Standard Range | Extended Customization |

Thickness | 9/18/22mm | 6-40mm (1mm increments) |

Width | 1220-2440mm | 600-2800mm |

Length | 2440-5500mm | 1000-8000mm |

Special | - | Moisture/Fire-retardant boards (Formaldehyde ≤0.03mg/m³) |

Ⅵ.Thickness Adjustment Technology

✅ 9→22mm Changeover Procedure:

1. Forming Adjustment:

Scraper height from 4.5mm→1.8mm

Strand flow reduced by 45% (VFD control)

2. Press Reset:

Pressure from 4.5MPa→2.8MPa

Zone temp: front zone ↑210℃, rear zone ↓190℃

3. Sanding Compensation:

Coarse sanding +0.5mm

Fine belts switched to 240 grit

Customization Limits

Parameter | Physical Limit | Technical Solution |

Min Width | 600mm | Narrow forming head + edge press |

Max Length | 8000mm | Board acceleration system (sync error ≤0.1%) |

Fire Retardant | OI≥30% | Dedicated resin injection unit (12-15% add-on) |

Ultra-Thin | 6mm thickness | High-pressure pre-press (1500N/mm line pressure) |

Deep technical annotation

1. Design of drying tower thermal efficiency

Adopting three-channel counter-flow heat exchange:

▸ Channel 1 (high-temperature zone): Inlet flue gas at 350℃ → Sawdust moisture content reduced from 45% to 20%

▸ Channel 2 (medium-temperature zone): 180℃ balanced evaporation → Moisture content 20% → 8%

▸ Channel 3 (low-temperature zone): 120℃ slow drying → Final moisture content 3 ± 0.5%

2. Continuous press machine precision control

Thickness adjustment response chain:

Thickness gauge data → Siemens PLC → Hydraulic servo valve (response time 80ms) → Partitioned cylinder displacement

During production of 22mm plates:

▸ Pressure zones 1-3: High-pressure zone (4.5MPa, 210℃) for rapid thickness setting

▸ Pressure zones 4-6: Medium-pressure zone (3.2MPa, 200℃) for curing the adhesive layer

▸ Pressure zones 7-8: Low-pressure zone (1.8MPa, 190℃) for stress release

3. Customized production verification data

Customized project | Measured performance |

2800mm ultra-wide plate | Density deviation ≤ 2.8% (full width) |

6mm thin plate continuous production | Plate tensile strength ≥ 18MPa (EN 319 standard) |

Flame-retardant plate (OI 32%) | Formaldehyde emission 0.025mg/m³ (F★★★★ grade) |

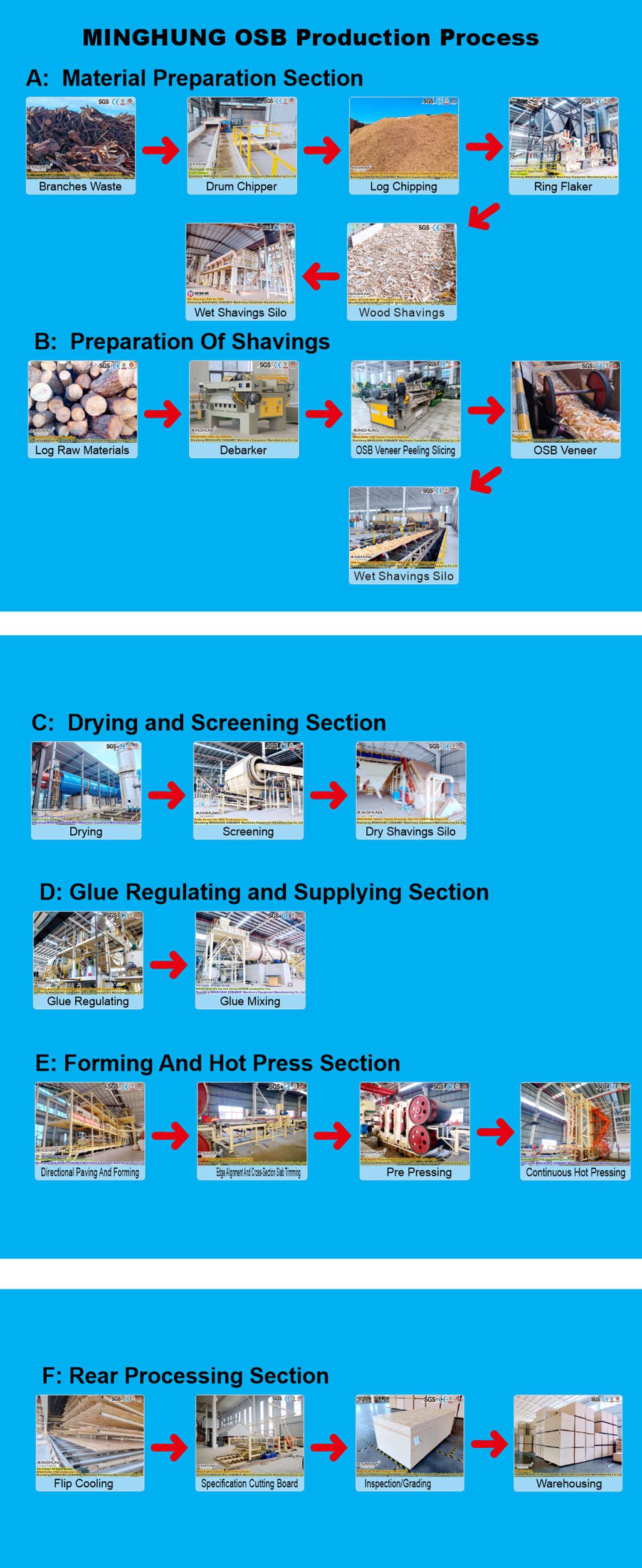

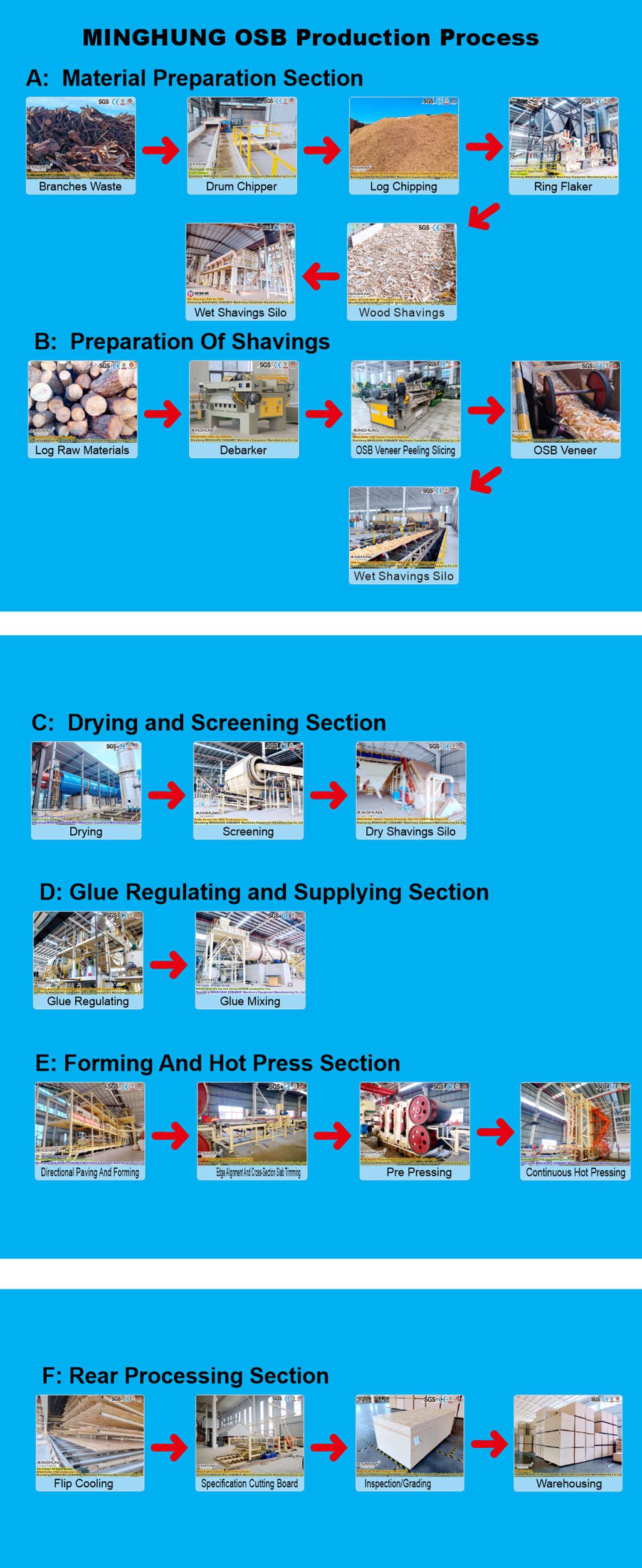

Shandong MINGHUNG Wood Based Panel Machinery is china professional factory and supplier of OSB board making machine, MDF/HDF making machine and Flakeboard/Particleboard making machine. Whatever which size, thickness, capacity you want to make, and whatever what kinds of raw materials do you use, our professional team can offer a suitable and good solution for you.

From A to Z, from Raw materials to the final wood based panel, we can offer you all necessary machinery. including: Wood chipper, Strander, Disc chipper, Ring flaker, Rotary drum dryer, Vibrating screener, Glue dosing and applying system, Refiner, Mat frorming line, Continuous pre-press, synchronous Cross-cut saw, Multi-layers Hot press /Continuous single layer hot press, Auto edge trimming machine line,Sanding line,etc.

In different conditions such as raw materials different, panel thickness and capacity different, glue types different, the whole production line can be different.

Submit your size requirements for a tailored capacity plan and quotation.

Our contacts:

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com