01 PRODUCT DESCRIPTION

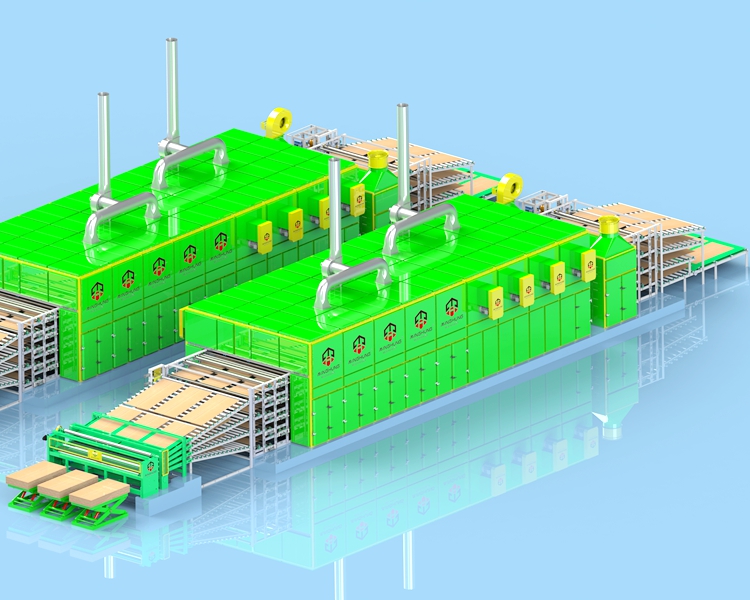

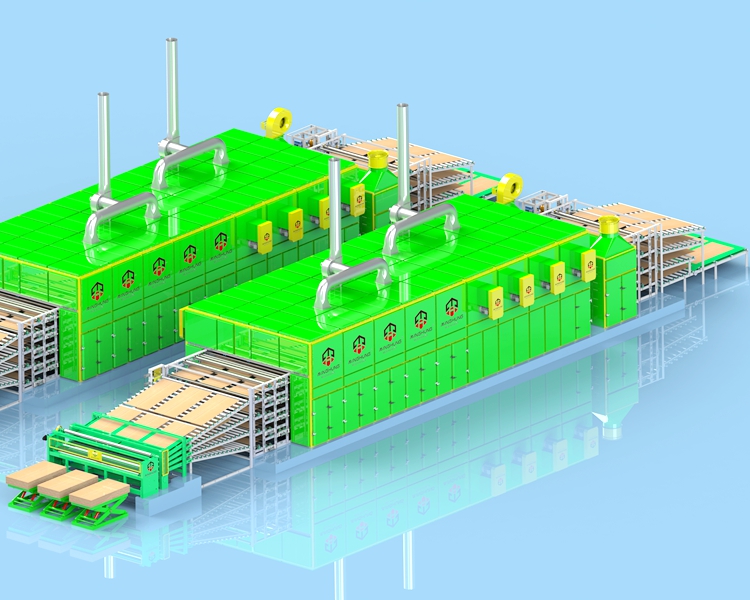

| BRIEF INTRODUCTION: MINGHUNG veneer dryer is a dryer specially developed for traditional dryers with high energy consumption, low drying efficiency, uneven drying of veneers and high mechanical failure rate. This model has high energy consumption and high heat conversion rate. , The drying veneer is flat, the failure rate is low, and the pain point of the traditional dryer is solved.

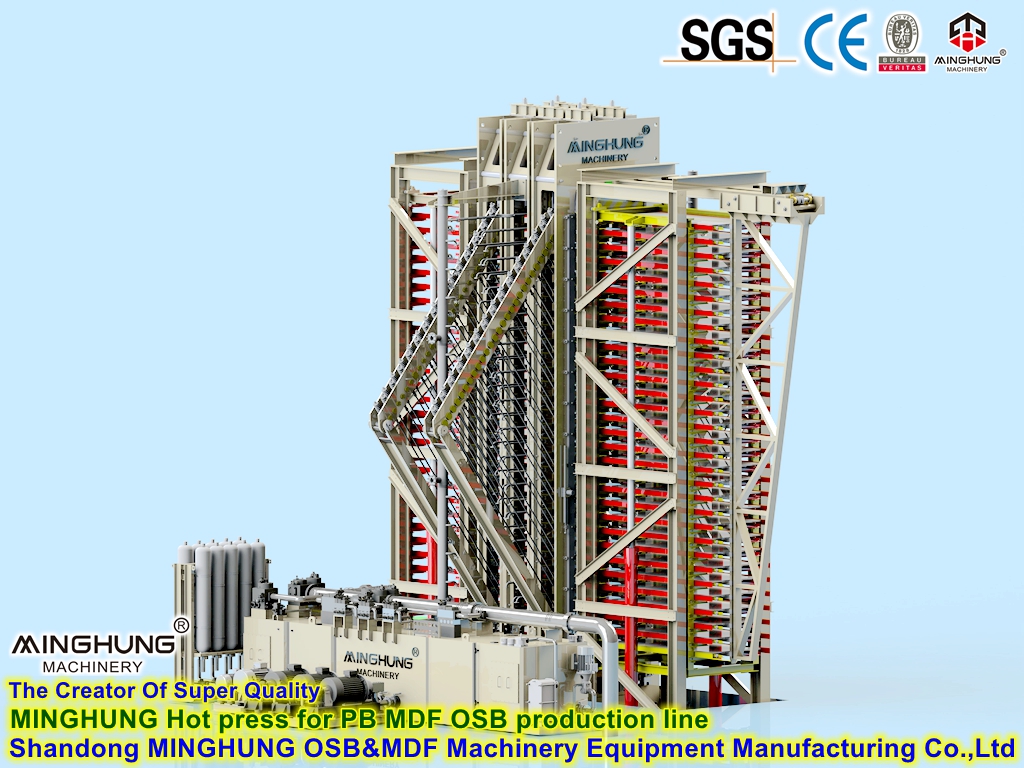

CLASSIFICATION: 1.Mesh belt veneer dryer: In this method, the veneer is placed on a mesh conveyor belt and subjected to hot air circulation. 2. Roller veneer dryer: This method involves passing the veneer through a series of heated rollers, which gradually remove moisture from the wood. 3. Hollow type veneer press dryer: Direct contact with the heated plates or cylinders, which press and dry the veneer simultaneously. |

02 PRODUCT ADVANTAGES

1. High output at low temperature

Ensure the flexibility and flexibility of the veneer, fast speed and large output. According to the needs of different users and different materials, the output of the equipment can reach 3-4 cubic meters per hour.

2.Smaller shrinkage than all dryers

In order to achieve the flatness of the drum, we optimize the density of the internal machine structure to reduce the pressure, completely solve the problem of the flatness of the veneer, and avoid the problem of reducing the size of the veneer caused by excessive pressure.

3. High degree of automation

Automatic feeding and labor saving, automatic dehumidification, low cost of consumables, high efficiency and energy saving, low power consumption, the equipment adopts all-aluminum fin heating device, large heat exchange area, fast heating, large circulating air volume, and many cycles.

4. longer cold air area

To prevent the phenomenon of returning moisture, the length of the cold air area is longer than that of the traditional dryer, the cooling effect of the veneer is better, and the drying is even. The stripped veneer undergoes multi-stage heat exchange and dehumidification.

03 PRODUCT DETAILS

|  |

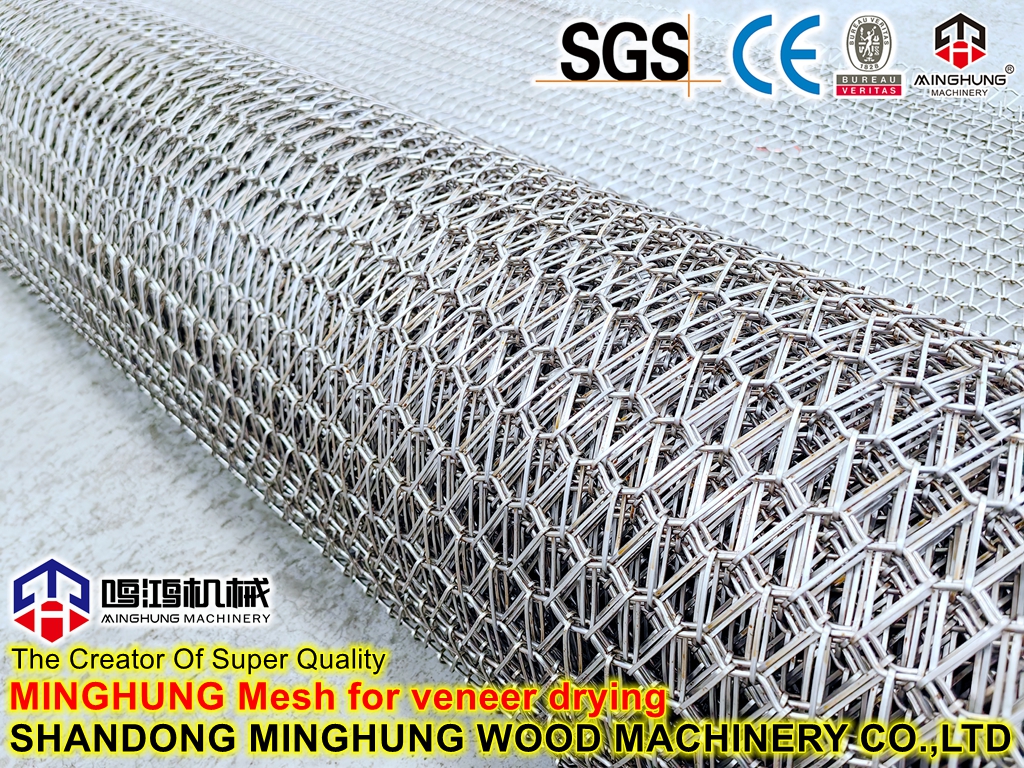

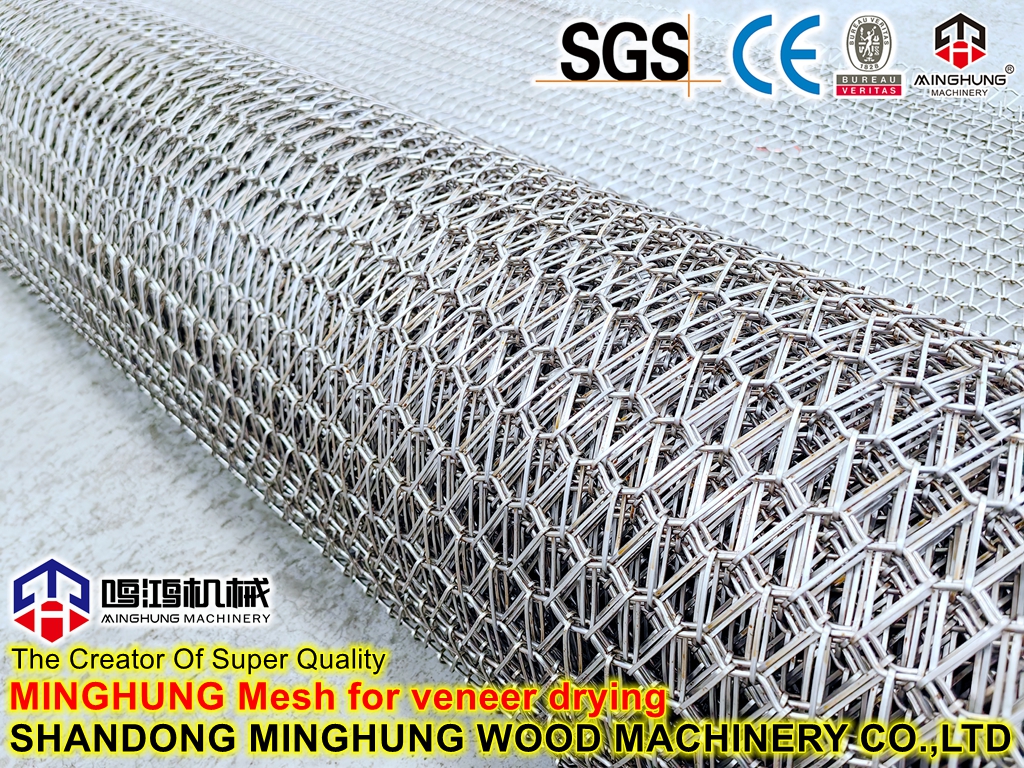

Quality of 304 Stainless Steel Mesh Bags: High-quality 304 stainless steel mesh bags are utilized, offering corrosion resistance and durability enhancements. |

|  |

All-Aluminum Fin Design: Our exclusive all-aluminum fin design offers excellent heat dissipation and high heat transfer efficiency, contributing to improved drying efficiency. |

|  |

Unique Air Duct Design: Our air ducts feature a unique design with directional splitting to ensure smooth airflow, enhancing drying effectiveness. |

|  |

Automation Control System: The wood drying machine is equipped with a PLC control system and a one-key operation screen, making operation simpler and more convenient. |

|  |

Application of Linear Guides: Combining linear guides with the correction system enhances the correction effectiveness by 50%, ensuring stable operation of the mesh bags. |

04 EXHIBITION

05 COMPANY PROFILE

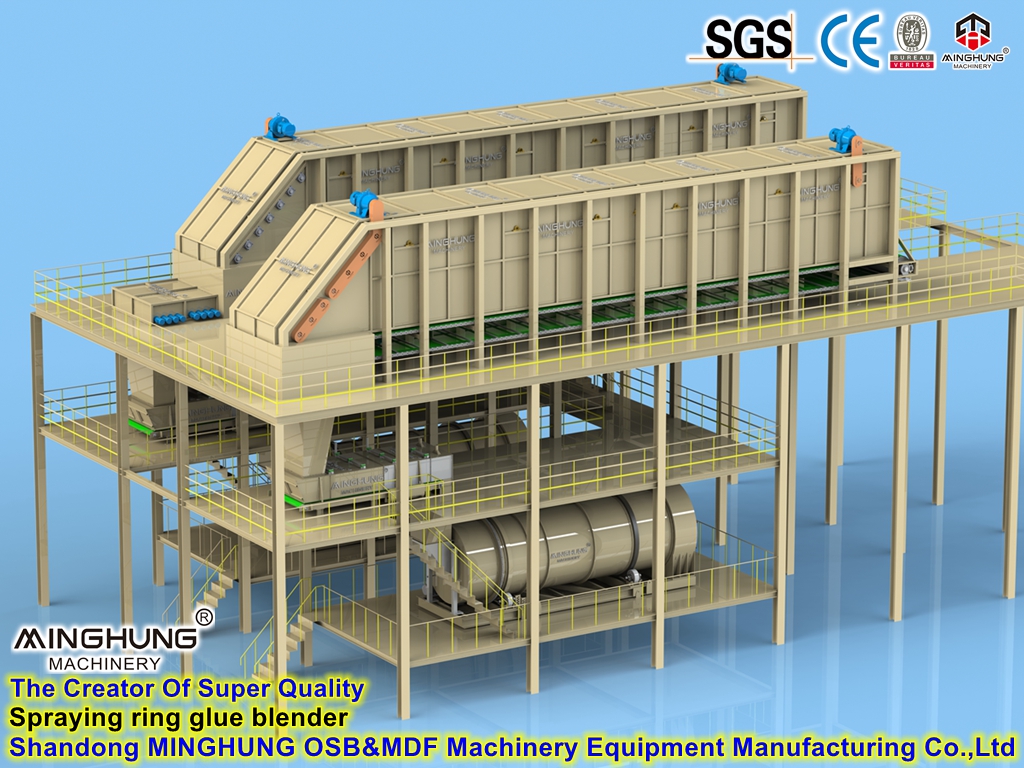

Shandong Linyi Minghong Wood Machinery Co., Ltd. is a professional enterprise specializing in the production of wood processing equipment. Located in Linyi City, Shandong Province, our company possesses advanced production techniques and equipment. We mainly manufacture wood drying machines, wood planers, wood cutting machines, and other woodworking machinery equipment. Our products are reliable in quality and superior in performance. Over the years, we have been committed to providing customers with high-quality products and excellent services, earning widespread trust and praise from our customers. We are willing to cooperate with customers at home and abroad for mutual development and creating a better future together.

06 WHY CHOOSE US

Welcome contact us for more information

Welcome to contact us

Phone number/whatsapp: +86 18769900191 +86 15589105786 +86 15805493072 +86 15805497925

Email: minghungwoodmachinery@gmail.com

Website: www.plywoodmachineline.com