18 Pressure Zone Particleboard Continuous Hot Pressing Machine Servo Hydraulic System

I. System Architecture Design

1. Zoned Hydraulic Layout

18 independent pressure control units, each covering a press length of approximately 1.5–2.2m (total press length: 30–40m).

Cylinder grouping strategy:

Each zone equipped with 2 main cylinder groups (1 for upper/lower platen) + 4 auxiliary fine-tuning cylinders (compensating local deformation).

Total cylinders: 18 zones × 6 cylinders = 108 independent actuators.

2. Servo Hydraulic Power Module

Component | Specifications & Technical Features |

Servo Motor-Pump Units | 18 high-pressure variable pumps (single pump power: 45–75kW), each independently driving one pressure zone; permanent magnet synchronous motors (>95% efficiency). |

Closed-Loop Valve Blocks | High-response proportional servo valves (response time <10ms), integrated pressure/flow dual-feedback sensors (±0.5% FS accuracy). |

Accumulator System | Nitrogen accumulators (total capacity: 300–500L), absorbing pressure fluctuations (ripple <±0.3MPa). |

Hydraulic system

Hydraulic system

Servo Motor

1. Multi-Stage Pressure Closed-Loop Control

Target Pressure Curve --> PLC Master Controller --> Zone Servo Controller --> Real-time Pressure Sensor Feedback --> PID Dynamic Adjustment of Servo Motor Speed --> Precise Cylinder Output Pressure Tracking

Control cycle: ≤5ms (10× faster than conventional hydraulics)

Pressure overshoot: <1%

2. Anti-Interference Mechanisms

Mat thickness variation compensation: Laser thickness gauge data → real-time cylinder pressure adjustment (response <0.2s).

Belt misalignment suppression: Edge cylinder pressure fine-tuning (±2MPa) to prevent platen overload.

III. Key Performance Parameters

Metric | 18-Zone Servo System | Conventional Proportional Valve System | Improvement |

Pressure Control Accuracy | ±0.2 MPa | ±0.8 MPa | 300% higher precision |

Thickness Tolerance | ±0.15 mm | ±0.35 mm | 12% higher yield rate |

Dynamic Response Speed | <10 ms | 80–100 ms | 8× faster |

Energy Consumption | 0.8–1.2 kWh/m³ | 1.8–2.5 kWh/m³ | 40–50% savings |

Pressure Fluctuation | ≤±0.3% | ≤±1.5% | 5× higher stability |

1. Enhanced Process Adaptability

Flexible pressure curves: 18 independently programmable zones support 5 preset profiles (e.g., high-pressure front-shift for moisture-resistant boards, extended holding for fire-retardant boards).

Rapid product changeover: Automatic pressure curve matching during specification switches (<3 minutes).

2. Defect Control Capabilities

Blister suppression: Step-pulsed pressurization in Zones 1–3 (20MPa→15MPa→22MPa) to forcibly evacuate steam.

Delamination prevention: Gradient pressure relief in Zones 16–18 (0.5MPa/s slope) to eliminate internal stress.

3. Maintenance & Reliability

Valveless design: Eliminates proportional valve stacks, reducing failure points by 60%.

Smart diagnostics:

Cylinder leakage monitoring (pressure retention rate >98%/10min)

Servo motor temperature alerts (>85℃ auto-derating)

Ⅴ. Application Scenarios for 18-Zone Systems

1. Production Line Tier

Economy-Grade Lines: Designed for small/medium particleboard plants with daily output of 600–1,200 m³ (18mm standard board). Targets cost-sensitive projects meeting basic national standards (e.g., density deviation ≤5%).

Mid-Range Products: Primarily produces standard particleboard, E1-grade boards, and limited moisture-resistant boards (V313). Not suitable for ultra-thin boards (≤3mm) or specialty boards (e.g., B1 fire-retardant).

2. Thickness Compatibility

Optimal range: 6–30mm

Thickness tolerance: ±0.15mm (superior to ±0.35mm in proportional valve systems but inferior to ±0.08mm in 48+ zone systems).

3. Line Speed Matching

Compatible speed: 500–800 mm/s. Requires ≥24 zones if speed exceeds 1,000 mm/s (insufficient dwell time in high-pressure zone).

Ⅵ. Performance Comparison: 18-Zone vs. Alternatives

Metric | 18-Zone | 12-Zone | 24-Zone |

Thickness Tolerance | ±0.15mm | ±0.30mm | ±0.12mm |

Density Uniformity | Deviation ≤4% | Deviation ≤6% | Deviation ≤2.5% |

Compatible Thickness | 6–30mm | 8–40mm | 3–40mm |

Energy Consumption | 0.8–1.2 kWh/m³ | 1.0–1.5 kWh/m³ | 0.7–1.0 kWh/m³ |

Investment Cost | Baseline | 15–20% Lower | 25–30% Higher |

The 18-zone system is the technical sweet spot for economy-grade lines: Delivers 80% of premium performance at 60% cost for 600–1,200 m³/day output, ideal for budget-conscious mid-tier manufacturers.

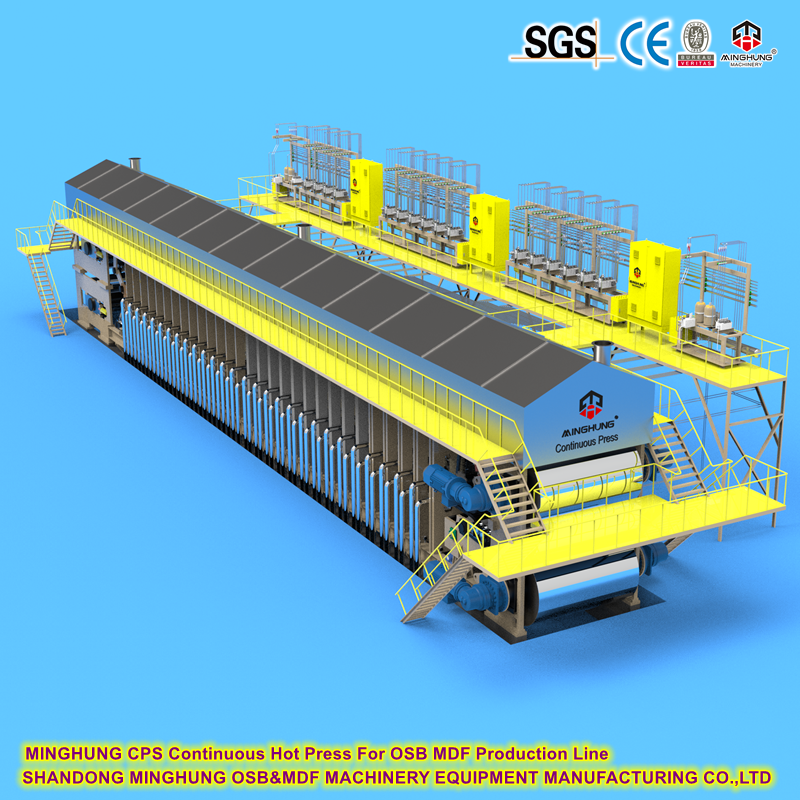

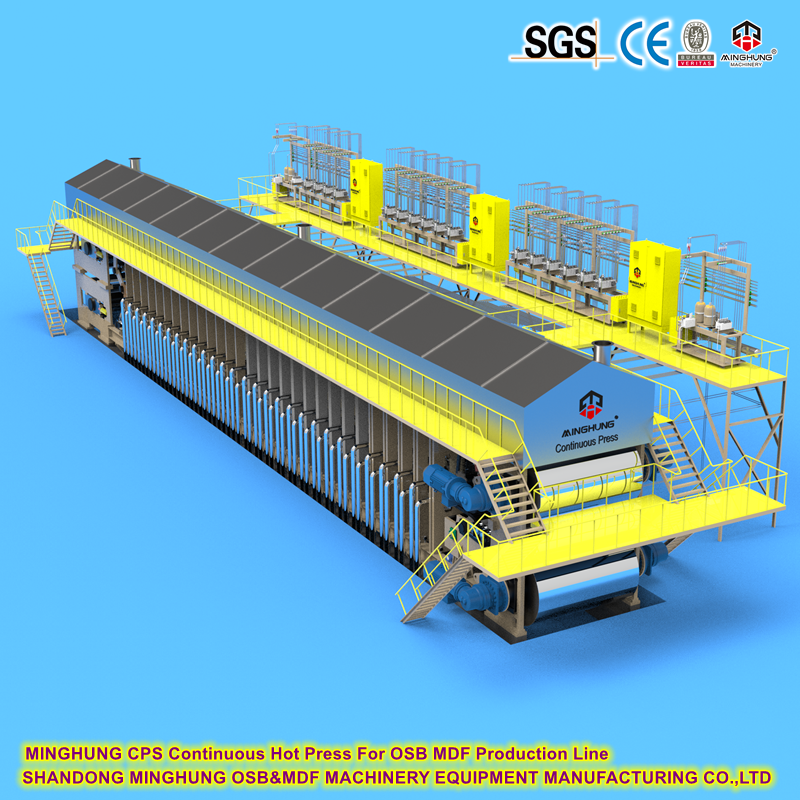

1. Working Principle

The core of the continuous flat hot press is to continuously press the slab through high temperature and high pressure. Its working process is as follows:

Feeding: The slab after paving and forming is sent to the entrance of the hot press through a conveyor belt.

Preheating and pre-pressing: Before the slab enters the main pressing area, the adhesive is softened by a preheating device and the air is expelled by pre-pressing.

Main pressing: The slab enters the pressing area composed of multiple layers of hot pressing plates, and is continuously pressed under high temperature (usually 180-250℃) and high pressure (2-5 MPa) to solidify the adhesive and tightly combine the fibers.

Cooling and board discharge: The pressed board is cooled and shaped in the cooling section, and then cut into standard sizes.

2. Core Structure and Composition

Hot press plate system: Composed of multiple heating plates, the interior is heated by heat transfer oil or steam to provide uniform temperature.

Steel belt system: Two circulating steel belts (upper and lower) hold the slabs and run continuously to ensure uniform pressure transmission.

Hydraulic system: Pressure is applied through hydraulic cylinders, and the pressing force in different areas can be adjusted in sections.

Control system: PLC or computer control, real-time monitoring of parameters such as temperature, pressure and speed.

Auxiliary equipment: includes paving machines, pre-pressing machines, cooling sections, sawing systems, etc.

3. Technical advantages

Continuous production: Compared with intermittent presses (such as multi-layer hot presses), production efficiency is greatly improved.

Stable quality: pressure and temperature are evenly distributed, the density of the board is highly consistent, the internal stress is small, and it is not easy to deform.

Energy saving and environmental protection: high thermal energy utilization rate, sufficient curing of adhesives, and reduced formaldehyde release.

Flexibility: The pressure curve can be adjusted to adapt to the production of boards of different thicknesses and densities.

4. Application areas

Man-made board manufacturing: mainly used for particleboard, medium-density fiberboard (MDF), high-density fiberboard (HDF), OSB, etc.

Furniture industry: production of substrate boards for custom furniture, cabinets, etc.

Building decoration: manufacturing floor substrates, wall panels, sound insulation materials, etc.

Packaging and transportation: production of high-strength pallets, car floor panels, etc.

Customize Your Line! Full-service solution from layout design to production optimization. Request a tailored proposal now.

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com