Frame & Casing: A robust steel structure with internal thermal insulation to minimize heat loss.

Heated Roller System: The core component, consisting of multiple sets (often dozens) of chrome-plated steel rollers with hollow cores for thermal medium circulation.

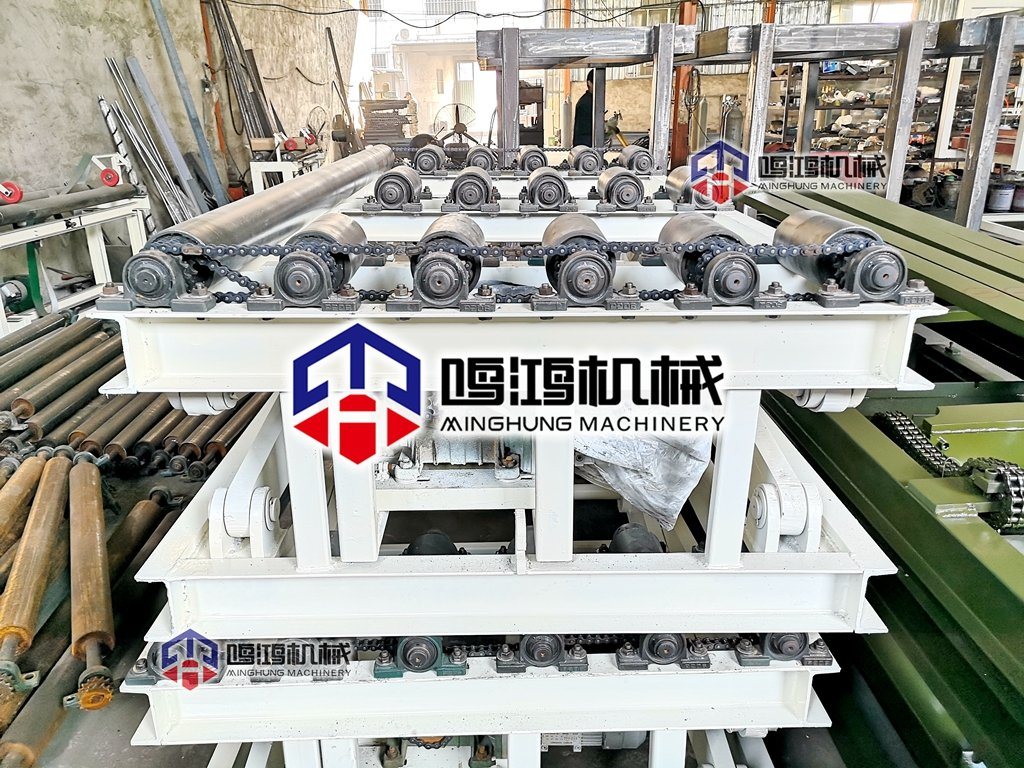

Drive System: Motors, gear reducers, and chain/gear sets ensuring synchronized and smooth rotation of all rollers, preventing veneer misalignment or jamming.

Heat Source System: Can be a steam boiler, thermal oil heater, or direct gas-fired system, providing thermal energy for the rollers and air circulation.

Hot Air Circulation & Exhaust System: Includes fans, ducts, heat exchangers, and exhaust dampers for uniform hot air distribution and forced moisture removal.

Control System: Modern models are equipped with PLC or microprocessor control systems for precise setting and adjustment of drying temperature (typically 120°C - 180°C), conveyor speed (determining dwell time), humidity, and other parameters.

|

Prominent Technical Features

High-Efficiency Continuous Production: Veneer passes through the dryer continuously, allowing non-stop feeding and discharging, significantly increasing output compared to batch-type dryers.

Uniform Drying Quality: Direct contact conduction heating from the rollers is highly efficient. The veneer is flattened by the rollers, effectively reducing shrinkage, warping, and cracking, resulting in excellent drying uniformity.

High Thermal Efficiency: Combining conduction and convection heating with effective insulation and air circulation leads to relatively low energy consumption.

High Automation Level: Can be integrated with upstream veneer lathes and downstream processes like splicing, patching, and stacking to form an automated production line.

Strong Adaptability: Capable of processing veneers of different wood species (e.g., poplar, eucalyptus, pine) and thicknesses (typically 1.0mm - 3.5mm) by adjusting roller speed (dwell time) and temperature.

|

Advantages

Massive Output: Ideal for large-scale industrial production.

Stable Drying Quality: Excellent preservation of veneer flatness.

Mature & Reliable Technology: Stable operation with relatively simple maintenance.

High Comprehensive Energy Efficiency: Competitive energy consumption per unit under continuous operation.

It serves as the critical bridge between the “veneer peeling” and “veneer preparation/hot pressing” stages. Wet veneer (with initial moisture content typically 60%-120%) must be dried by this machine to a suitable level (usually 6%-12%) before it can proceed to subsequent steps like repairing, gluing, and hot pressing. It plays a decisive role in the final plywood product's strength, flatness, and stability.

|

Product Packaging

|

Company Profile

We are Shandong MINGHUNG Wood Based Panel Machinery Co.,Ltd China factory and manufacturer of full sets of Plywood machinery and Veneer machinery. With many years production experience, advanced production technology,experienced workers and professional engineers, we can offer you the suitable, good and strong machinery for you.

As a Chinese plywood machinery factory, we understand the importance of an efficient factory layout to maximize productivity and streamline operations.lf you are considering producing plywood and choosing our high-quality plywood machinery, we are here to assist you in designing a rational factory layout and arranging machine positions for optimal results.

|

Certifications

Our contacts:

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com