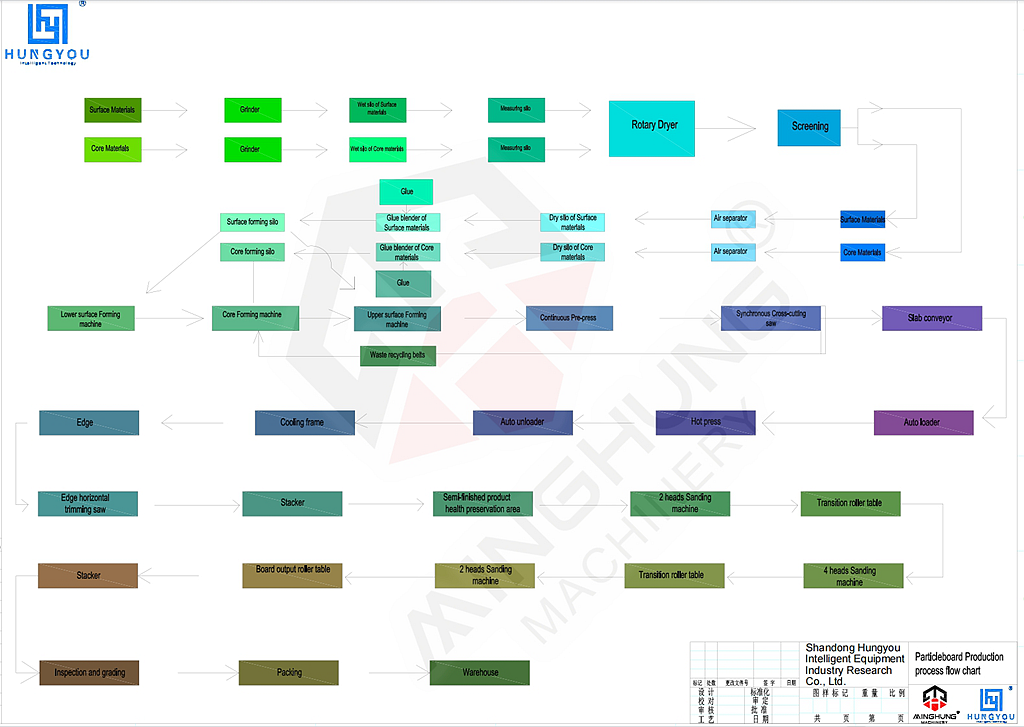

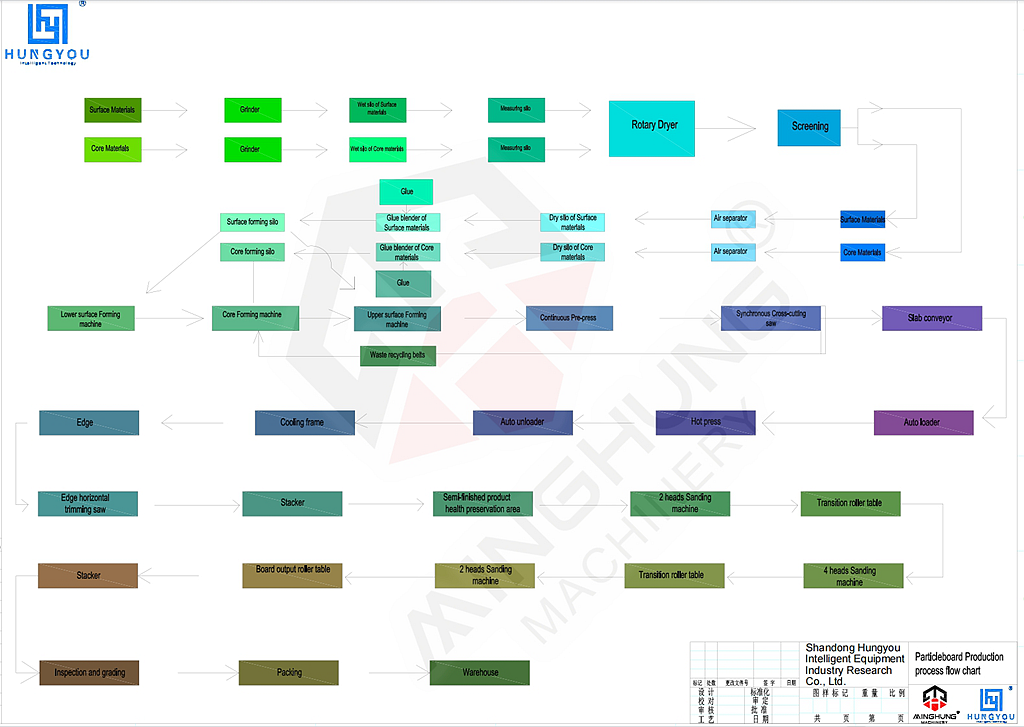

Production Process Introduction

This process is a continuous, highly automated operation, with its core objective being the transformation of complex recycled wood into high-quality, eco-friendly particleboard.

Stage 1: Raw Material Handling Section (Recycled Material Purification)

Purpose: To process complex recycled wood into clean, standardized raw material.

Detailed Process:

1.1 Crushing/Shredding: Recycled waste wood, construction formwork, etc., are fed via an apron conveyor into a Heavy-Duty Crusher and broken down into smaller fragments.

1.2 Multi-Stage Screening & Purification: The fragments pass through:

Vibrating Screen: Separates out fine dirt and oversized, unacceptable fragments.

Magnetic Separator: Uses powerful magnetic rolls to remove ferrous metals (e.g., nails, screws).

Air Classifier/Non-Ferrous Metal Separator: Utilizes differences in specific gravity and eddy currents to separate light materials like plastics, stones, and aluminum fasteners.

1.3 Storage: The purified, acceptable raw material is sent to a Raw Material Storage Silo for subsequent use, ensuring continuous production.

Stage 2: Particle Preparation & Drying Section

Purpose: To create uniformly sized particles and control their moisture content.

Detailed Process:

2.1 Flaking: The purified wood chips are fed into a Ring Flaker, where they are cut into uniformly sized flake-like particles by the high-speed rotating knife ring.

2.2 Drying: The wet particles are conveyed via belt conveyor into a Rotary Drum Dryer, where they fully contact hot air, reducing their moisture content from about 30%-50% to the required 2%-4%. Stable moisture content is key for subsequent blending and pressing quality.

2.3 Screening & Classification: The dried particles pass through a Screening Station and are precisely classified into Surface Fine Particles, Core Coarse Particles, and excess fine powder for recycling. This classification is fundamental for forming a high-quality mat structure.

Stage 3: Blending & Forming Section (Functional Injection & Mat Formation)

Purpose: To uniformly apply adhesive and additives to the particles and form them into a structurally stable mat.

Detailed Process:

3.1 Precision Blending: The classified surface and core particles enter separate Metering Bins, discharging at a preset, stable rate. They then enter a High-Speed Ring Blender:

Adhesive: Precisely sprayed E1 Grade Eco-Friendly Urea-Formaldehyde (UF) Resin or Melamine-Urea-Formaldehyde (MUF) Resin.

Waterproofing Agent: Simultaneously sprayed Paraffin Emulsion.

Other Additives: Hardener, etc., can be added as needed.

Inside the high-speed rotating blender, the particles become uniformly coated with the resin and additives.

3.2 Mat Forming: The blended particles are distributed by a Mechanical or Pneumatic Forming Station onto a moving steel belt, forming a uniform, loose mat. The forming technology determines the board's density distribution and structure (can produce graduated or oriented structure like OSB).

3.3 Pre-Pressing: The formed mat passes through a Pre-Press, where it is initially compacted and de-aerated, gaining strength to form a self-supporting "green belt" for smooth entry into the hot press.

Stage 4: Hot Pressing & Curing Section (Board Formation)

Purpose: To cure the resin under high temperature and pressure, permanently bonding the loose mat into a high-density board.

Detailed Process:

4.1 Continuous Hot Pressing: This is the core stage of the production line. The mat enters the Continuous Flat Press, passing continuously through a long press with heated platens. The system executes a precise "Temperature-Pressure-Time" profile, causing the resin inside the mat to cure rapidly under high temperature (approx. 180-210°C) and pressure, firmly bonding the particles together.

4.2 Cooling & Trimming: The hot board exiting the press enters a Cooler/Conditioning Star, where it is forcibly cooled to a safe temperature, finalizing its set. Then, via Trimming & Cross-Cut Saws, the board is cut to the required dimensions, and the irregular, harder edges are trimmed off.

Stage 5: Finishing Section

Purpose: To perform final precision processing on the board.

Detailed Process:

5.1 Sanding: The board enters a Calibrating Sander for precision sanding of both top and bottom surfaces. This step is crucial as it:

Ensures precise final thickness (e.g., ±0.2mm).

Achieves high surface flatness, providing a perfect substrate for subsequent finishing processes like laminating or printing.

5.2 Cutting-to-Size & Stacking: According to customer order requirements, the sanded board is cut to its final size (e.g., 1220x2440mm) by a Panel Saw and then stacked by an Automatic Stacker.

Stage 6: Inspection & Packaging Section

Purpose: To ensure product quality and prepare it for storage and transport.

Detailed Process: Finished boards are sampled for testing key indicators like formaldehyde emissions, internal bond strength, and modulus of rupture. Qualified products are shrink-wrapped or packaged via an Automatic Packaging Line to prevent moisture and scratches, and finally sent to storage.

1. Raw Material Handling Equipment:

Apron/Belt Conveyor: Material transport.

Heavy-Duty Crusher: Primary crushing of large recycled wood.

Multi-Stage Vibrating Screen/Swinging Screen: Screens and classifies material by size.

Powerful Magnetic Separator (Permanent/Electromagnetic): Removes ferrous metals.

Air Classifier/Non-Ferrous Metal Separator: Removes light impurities and non-ferrous metals.

2. Particle Preparation & Drying Equipment:

Ring Flaker: Produces uniformly sized particles.

Rotary Drum Dryer: Equipped with a thermal energy system for drying particles.

Particle Screening Station (Swinging Screen/Air Classifier): Classifies dried particles into surface and core layer materials.

flaker

dryer

vibrating screen

3. Blending & Forming Equipment:

Surface & Core Layer Particle Metering Bins: Ensure a stable supply of particles at a set ratio.

High-Speed Ring Blender: Achieves uniform mixing of resin, additives, and particles.

Resin & Wax Preparation/Storage/Dosing System: Includes storage tanks, pumps, and precision flow meters.

Mechanical Forming Station/Pneumatic Forming Station: Forms a uniform mat.

glue mixer

forming machine

4. Hot Pressing & Curing Equipment:

Pre-Press: Performs initial compaction of the mat.

Continuous Flat Press: The core and highest-value equipment of the entire production line, enabling continuous high-pressure forming and curing of the board.

Mat Conveying, Weighing & Metal Detection System: Ensures the mat entering the press is qualified.

pre press

continuous press

5. Finishing & Handling Equipment:

Cooler/Conditioning Star: Allows the board to cool uniformly.

Trimming & Cross-Cut Saws: Includes edge trimmers and cross-cut saws for sizing length and width.

Calibrating Sander: Ensures final board thickness and flatness.

Panel Saw & Automatic Stacker: Performs final size cutting and stacking.

dryer rack

cross-cut saw

sander

6. Auxiliary & Control Systems:

Central Automated Control System (PLC + SCADA): The "brain" of the production line.

Thermal Energy Plant (Boiler/Thermal Oil Heater): Provides the required heat source for production.

Dust Extraction System (Cyclone Separators + Baghouse Filters): Collects and treats dust from the entire line.

Hydraulic & Pneumatic Systems: Provide power for various actuators.

PLC

energy plant

hydraulic

Technologies & Process Characteristics

1. Efficient Recycled Raw Material Handling System

Core Technology: Equipped with a heavy-duty crusher, multi-stage screening system (vibrating screens, air classifiers), and powerful magnetic/non-ferrous metal separators. This system effectively processes complex recycled wood streams, removing impurities like sand, stones, plastics, and metals, ensuring raw material purity—the prerequisite for final board quality.

Advantage: Achieves "upcycling" of municipal solid waste and wood processing residues, significantly reducing raw material costs and dependence on virgin timber.

2. Advanced Resin Blending & Environmental Control Technology

E1 Grade Assurance: Utilizes a high-precision dosing and blending system with E1 grade or ultra-low formaldehyde Urea-Formaldehyde (UF) resin or more environmentally friendly Melamine-Urea-Formaldehyde (MUF) resin. Through optimized resin formulations and curing processes, formaldehyde emissions are strictly controlled, ensuring products meet or exceed E1 grade international standards (e.g., EU EN 13986).

Blending Uniformity: High-speed ring blenders ensure resin, wax, and other additives uniformly coat each wood particle, ensuring board strength while minimizing resin consumption for energy and cost savings.

3. High-Capacity Continuous Press Technology

Core Equipment: The heart of the line is typically a Continuous Flat Press. It enables continuous operation from forming and pre-pressing to hot-pressing and cooling, offering high speed and efficiency, which is key to achieving the 120,000 m³ annual capacity.

Quality Advantage: Boards produced by a continuous press have extremely uniform density distribution, high surface flatness, and stable internal quality, making them particularly suitable for subsequent deep processing and finishing.

4. High Automation & Intelligence

Central Control Room: The entire line is controlled centrally by PLCs and a SCADA system, monitoring and automatically adjusting all process parameters (e.g., particle size, moisture content, resin dosage, press temperature/pressure/speed) in real-time.

Quality Stability: Automated production minimizes human factor influence, ensures consistent quality across batches, and reduces operational difficulty and labor costs.

5. Energy Recovery & Environmental Design

Heat Recovery: Integrated heat recovery units reclaim waste heat from the hot press and dryer system to pre-heat fresh air or process water, significantly reducing overall energy consumption.

Dust Extraction: Efficient baghouse dust collectors are installed to capture and treat dust generated during production, ensuring a clean workshop and compliant exhaust emissions.

Final Product Performance & Application Fields

Product Performance:

Environmental: Formaldehyde emission ≤ 0.124 mg/m³ (or complies with target market E1 standard).

Physical Properties: Key indicators like Internal Bond, Modulus of Rupture, and screw holding capacity meet or exceed national standards (e.g., GB/T 4897).

Stability: Uniform structure, minimal thickness tolerance, flat surface.

Application Fields:

Furniture Manufacturing: Substrate for cabinets, wardrobes, office furniture, panel furniture.

Interior Decoration: Floor underlayment, partitions, wall panels, ceilings.

Construction & Packaging: Can be used for construction formwork (non-load bearing) in dry environments, packaging crates.

Potential Development: Value and application range can be further enhanced through subsequent finishing like laminating or melamine paper overlay.

We are Shandong MINGHUNG Wood Based Panel Machinery Co.,Ltd China factory and manufacturer of full sets of Plywood machinery and Veneer machinery. With many years production experience, advanced production technology,experienced workers and professional engineers, we can offer you the suitable, good and strong machinery for you.

We maintain a long-term cooperation with a well-known freight forwarding company, and adhere to the customer-first philosophy. We strictly implement the quality inspection process before shipment to ensure that each batch of products meets international quality standards, We deeply understand that high-quality service is the cornerstone of winning customer trust, and we always create value for customers with professional and efficient supply chain management.

✅ Transform Your Production Now!

Request Your Customized Quote & Technical Proposal:

Call +86 18769900191, +86 15805496117, +86 18954906501 or 【Live Chat】

Get a productivity upgrade plan within 24h