Main Structure & Features

1. Corrosion-Resistant Stainless Steel Inner Chamber

Material: The entire drying chamber interior, air ducts, airflow guide plates, air plenums—all metal parts in contact with hot, humid air—are constructed from 304 or 316 stainless steel.

Advantages: Completely prevents rust and corrosion caused by acidic substances (e.g., tannic acid) leached from the veneer and long-term exposure to steam. Maintains interior cleanliness, prevents contamination, avoids rust particles from staining the veneer, and significantly extends the main equipment lifespan.

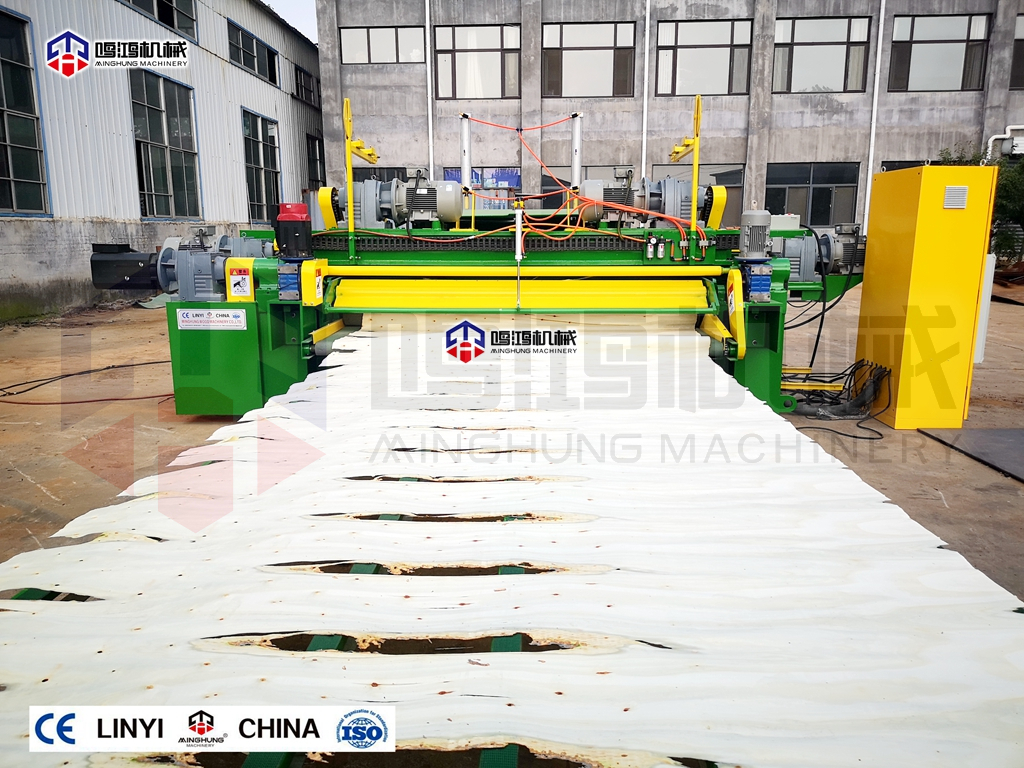

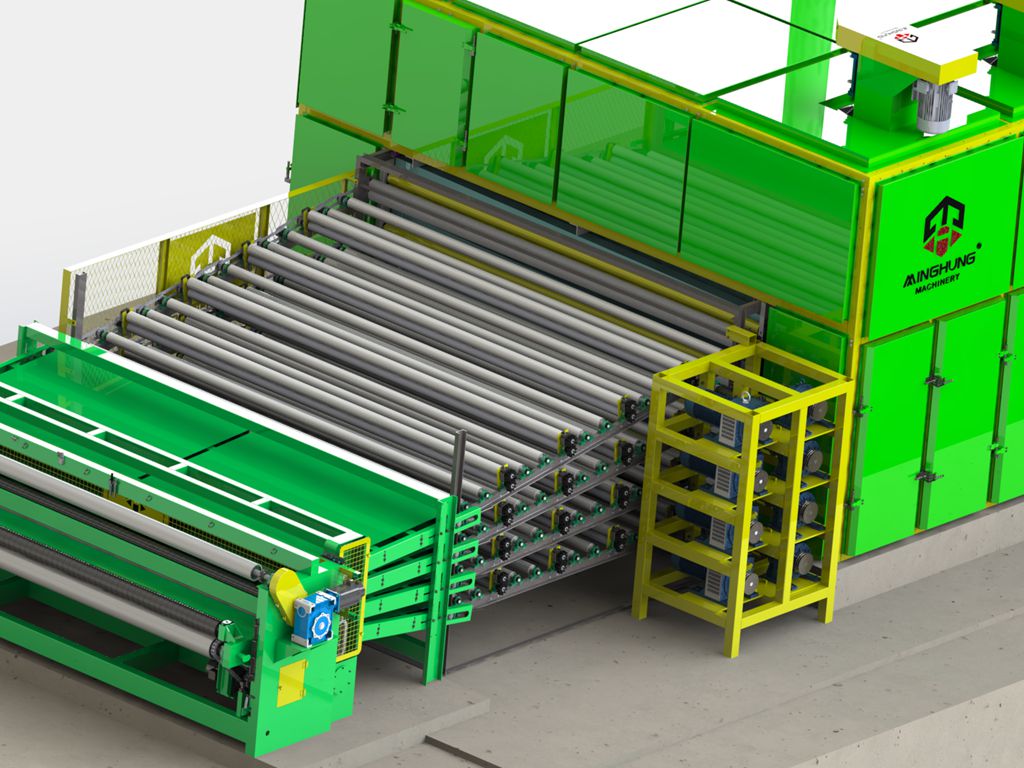

2. Mesh Belt Conveyance System

Material: The conveyor belt can be woven from stainless steel wire or heat-resistant galvanized steel wire, offering high-temperature and corrosion resistance.

Features: Excellent permeability allows hot air to penetrate from both sides for uniform drying. Stable operation with stepless speed adjustment to accommodate veneer of different thicknesses and initial moisture contents.

3. High-Efficiency Hot Air Circulation System

Components: Consists of high-temperature resistant centrifugal fans, stainless steel heat exchangers (options: steam, thermal oil, electric, or gas hot air furnace), and scientifically arranged supply/return air ducts.

Features: Forced circulation ensures uniform air speed, volume, and temperature distribution, resulting in high thermal efficiency and low energy consumption.

4. Intelligent Control System

Functions: Integrated PLC and touchscreen HMI allow for precise setting and display of parameters such as temperature in each drying zone, mesh belt speed, and humidity.

Advantages: Enables automated continuous production. Drying curves can be stored and recalled. User-friendly operation guarantees repeatability and stability of the drying process.

5. Insulated Casing

Structure: The casing is made of high-quality color steel plates with high-density rock wool insulation in between, effectively reducing heat loss, saving energy, and improving the workshop environment.

6. Moisture Exhaust System

Equipped with adjustable exhaust dampers or exhaust fans that regulate the moisture removal rate automatically or manually based on preset humidity parameters, ensuring optimal humidity levels inside the drying chamber.