|

Product Description

The 10mm Mold-Resistant OSB (Oriented Strand Board) Production Line is a large-scale, integrated wood-based panel manufacturing system that embodies automation, intelligence, and cutting-edge technology. It is specifically designed to transform small-diameter timber and forest thinnings (e.g., pine, poplar) into high-value-added 10mm thick mold-resistant OSB. By incorporating specialized anti-mold processes and precise quality control systems, this production line ensures the final product maintains exceptional structural stability and long-term durability even in humid environments, meeting the stringent material performance requirements of the global high-end construction and furniture markets.

|

Advantages & Features

1. Superior Mold & Moisture Resistance:

Dedicated Mold Inhibitor System: Equipped with a high-precision, integrated blending system for resin, wax, and mold inhibitors, ensuring even distribution and deep penetration of eco-friendly anti-mold agents throughout the wood strands.

Optimized Hot Pressing Process: Precise control over platen temperature, pressure, and time effectively cures the board and locks the mold-resistant components within, ensuring lasting protection.

2. High Automation & Intelligence:

Central Control System: Utilizes PLC and HMI for centralized control of the entire line, enabling one-touch start/stop, parameter setting, fault diagnosis, and remote monitoring, significantly reducing labor dependency.

Online Quality Inspection: Integrated moisture detectors, thickness gauges, and defect scanners monitor strand geometry, mat formation uniformity, and board density in real-time, ensuring consistent product quality.

3. Excellent Board Quality & Flexibility:

Precision Oriented Forming: Employs multi-head mechanical formers to achieve precise longitudinal and transverse orientation of strands in the surface and core layers, producing OSB with high bending strength and superior nail-holding power.

Flexible Formulation & Specifications: The line can adapt to different raw materials and adhesives (e.g., PF, MDI eco-friendly glue) and can easily produce OSB of varying densities and standard sizes by adjusting forming and pressing parameters.

4. Environmentally Friendly & Energy Efficient:

Energy Recycling: The design includes heat recovery systems that capture waste heat from dryers and presses to preheat fresh air or for use in other processes, significantly reducing energy consumption.

Clean Production: Efficient bag-house dust collectors and VOC abatement systems ensure dust and exhaust emissions comply with international environmental standards.

|

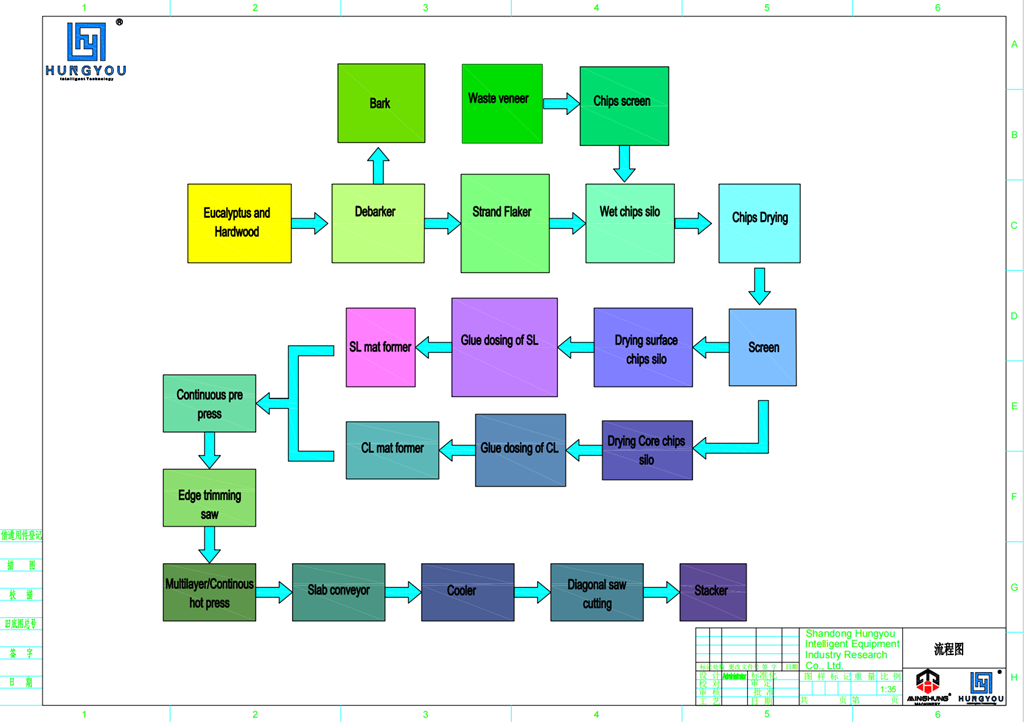

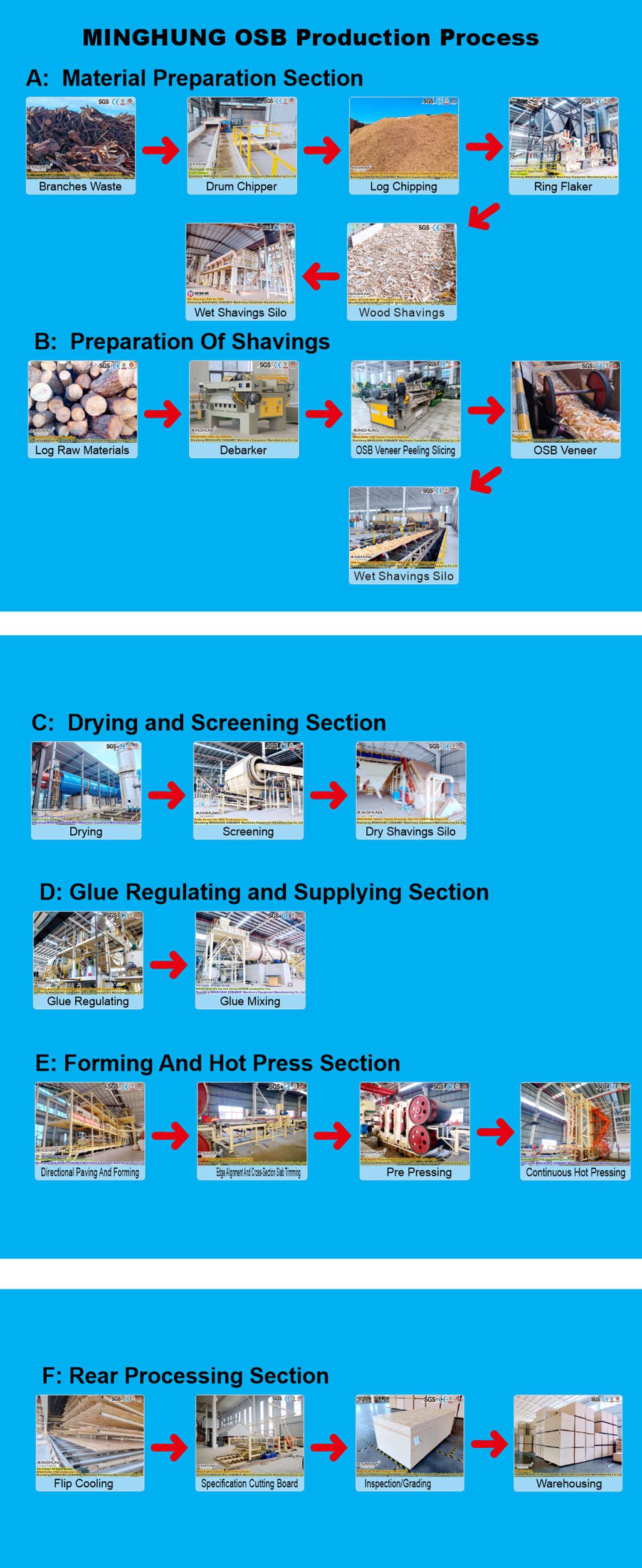

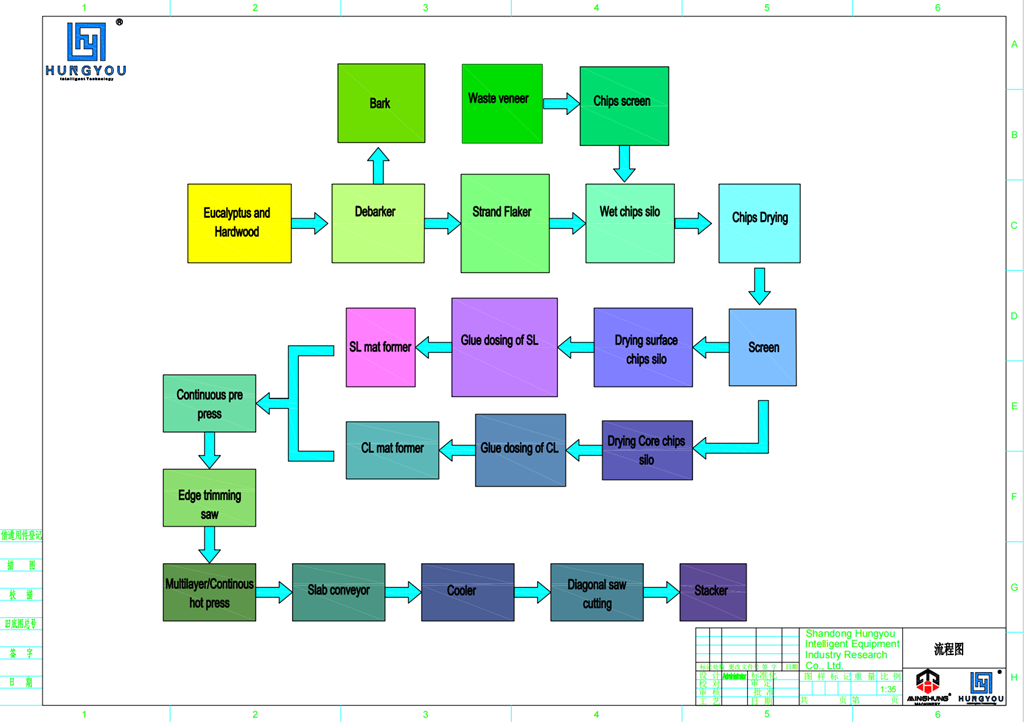

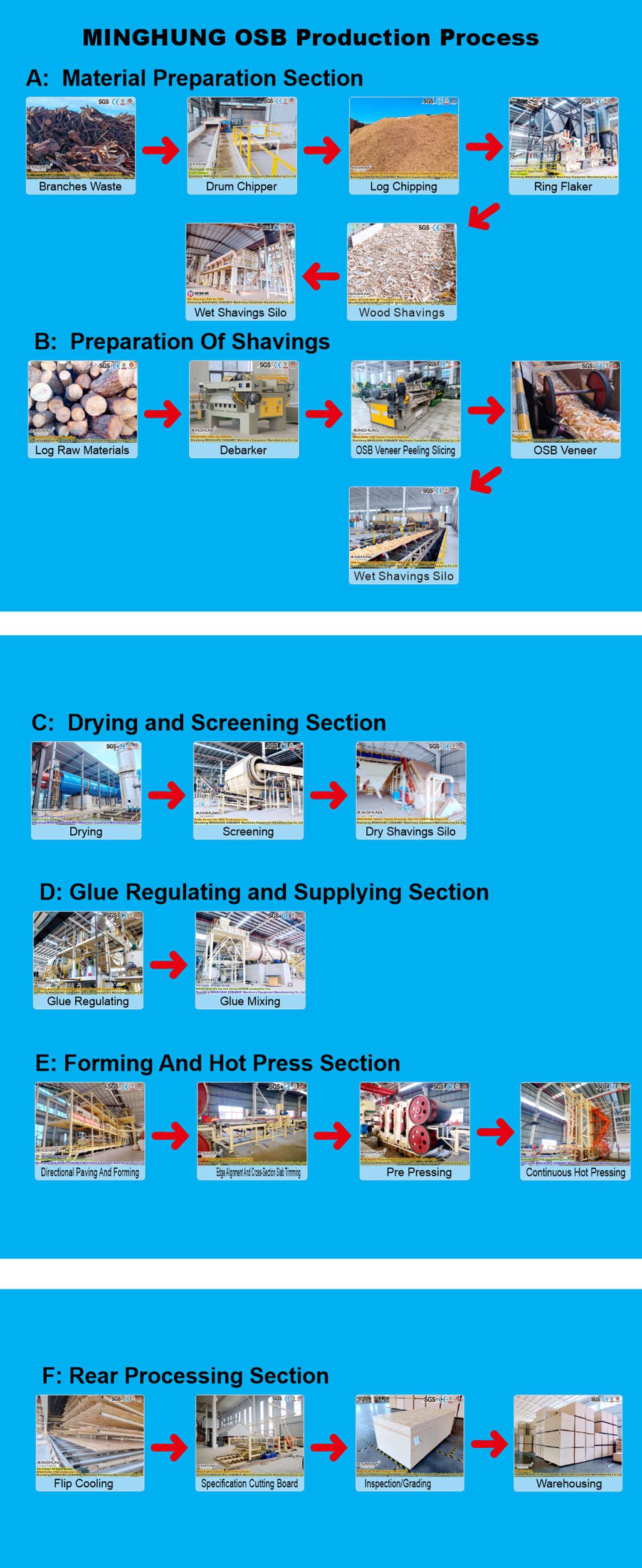

Main Process Flow & Components

A complete 10mm Mold-Resistant OSB production line typically consists of the following core sections:

1. Raw Material Preparation Section:

Chipping & Stranding: Logs are converted into chips by a drum chipper and then into precise strands by a ring strander.

Screening & Re-crushing: A vibrating screen separates acceptable strands from oversize and fines; oversize strands are sent to a re-crusher.

chipper

vibrating screen

2. Drying & Blending Section:

Rotary Dryer: Uses hot air to uniformly reduce strand moisture content from 40%-60% down to 2%-4%.

Blender: Dried strands enter a high-speed blender where they are thoroughly and uniformly mixed with resin, wax, and the core component—the mold inhibitor.

drying system

glue sizing system

3. Forming & Pressing Section:

Oriented Former: The heart of OSB production, it uses mechanical or air-assist methods to orient the resinated strands into a consistent, multi-layered mat on a conveyor belt.

Pre-pressing & Hot Pressing: A continuous pre-press initially compacts the fluffy mat, which is then fed into a multi-opening or continuous press. Under high heat and pressure, the resin cures, and the board is solidified into a sturdy 10mm thick panel.

forming machine

continuous hot press

4. Finishing Section:

Cooling & Trimming: Pressed boards are cooled on a star cooler and then cut to standard sizes by cross-cut and trim saws.

Sanding & Packaging: A wide-belt sander calibrates the board surfaces to ensure uniform thickness and smoothness, followed by automatic stacking and packaging.

cross-cut saw

sanding machine

|

Technical Parameters

Item | Parameter / Description |

Board Thickness | 10mm (Adjustable range typically 6-40mm) |

Raw Material | Pine, Poplar, Eucalyptus, and other small-diameter logs or chips |

Line Capacity | Annual Output 30,000 - 100,000 cubic meters (Depending on configuration) |

Board Size | 1220x2440mm, 1250x2500mm or Customized |

Board Grade | Meets OSB/3 (Load-bearing boards for use in humid conditions) standard |

Control System | Fully Automatic PLC control with remote monitoring interface |

Mold Resistance | Can achieve ASTM D3273 Rating 0 (No Growth) or equivalent standard |

|

Company Profile

We are Shandong MINGHUNG Wood Based Panel Machinery Co.,Ltd China factory and manufacturer of full sets of Plywood machinery and Veneer machinery. With many years production experience, advanced production technology,experienced workers and professional engineers, we can offer you the suitable, good and strong machinery for you.

The machinery we have produced not only includes a complete production line for plywood, but also a full range of production equipment for particleboard, density board, and fiberboard. The main machinery includes peeling machines, chipping machines, rotary cutting machines, drying machines, gluing mixers, laying machines, pre-pressing machines, hot pressing machines, cooling machines, longitudinal and transverse sawing machines, sanding machines, as well as auxiliary machinery such as automatic feeding and discharging systems and lifting platforms.

|

Production Workshop

|

Deliver Goods

We provide global installation support and technical training, 2-year machine warranty, and 24-hour online response - let your OSB production enter a new era of intelligence and low carbonization.