Plywood Composer Machine Veneer Splicing Machine

The core composer machine is one of the main equipment for the production of blockboard (large core boards), plywood panel. Through extrusion, heating and other processes to make a full size solid core plywood board equipment, the core composing machine is mainly composed of hydraulic system, pneumatic system and so on.

The core veneer composing line consists of five parts: the board machine host, the high-frequency generator, the hydraulic station, the feeder and the automatic stacker, and the control system. The core composer is controlled by PLC and has the characteristics of high degree of automation, simple and convenient operation, low labor intensity, short splicing cycle, and labor saving. The splicing size of the panel machine is usually 1250*2500mm, and the veneer thickness from 0.8mm to 5mm. When the user has special requirements, a customized configuration design can be made in advance. The equipment adopts high-frequency heating, which can quickly cure the glue in a very short time. The whole working process takes about 3-5 minutes.

| name | core composer |

| working width | 600-1270mm |

| working length | 600-2560mm |

| thickness | 1-4mm |

| length of knfie | 1350mm |

| feeding speed | 32m/min |

| power | 20kw |

| weight | 9000kg |

| size | 9100*2600*2300mm |

Note: core composer can customize acccording to your plywood size.

The advantages of core composer:

Factory:

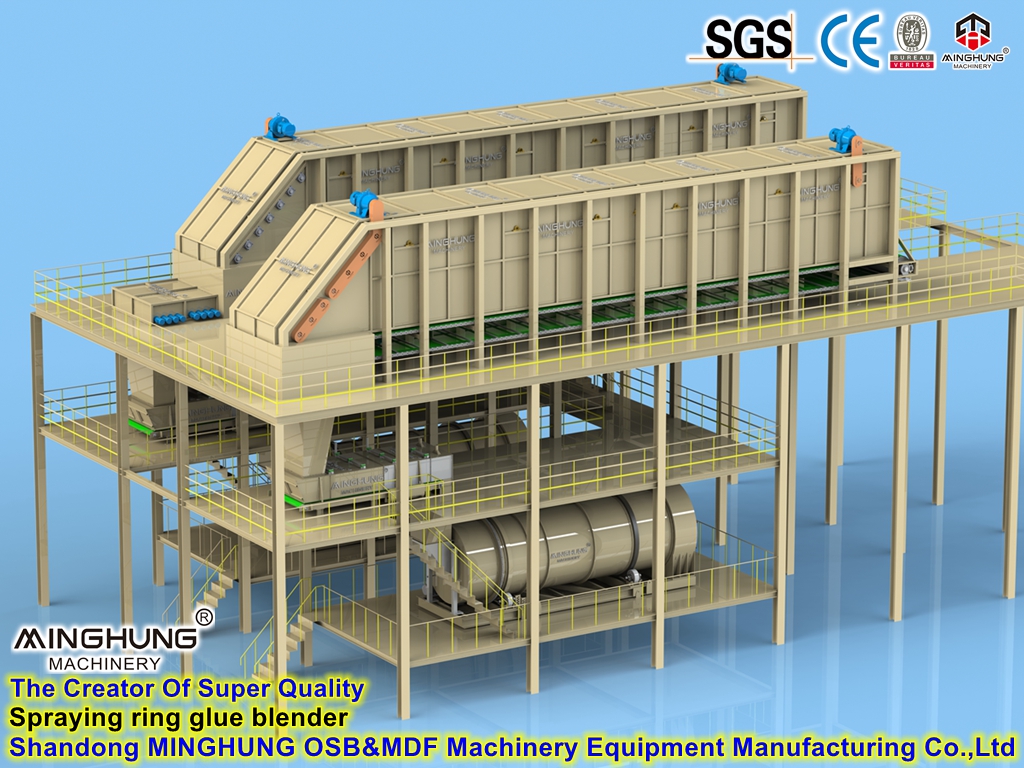

Shandong MINGHUNG Wood Machinery Co.,Ltd is one famous manufacturer of plywood machine in China, located in Linyi city. Our products have acquired EU CE, ISO 9001, ISO 14001, CCEP, and Energy Conservation Certification.

Our company integrates design, research and development, production and sales, and works closely with China's advanced scientific research institutions. We have a strong research and development team, at present, our machinery has won a number of national patents.

Pay more attention to machine details, details determine sucess or failure, so we continuous improve and optimize machines' performance, strictly control each production step, using advanced lathe processing machine, and through many times inspections, make sure our machine accurate and durable.

Scientific and technological innovation oriented, quality-based, service supremacy, we offer full complete range of plywood production solution and technology support for our customers. Yet our machines have been exported more than 30 countries and regions like Russia, Poland, Ukraine, Portugal, Bulgaria, Romania, Turkey, Egypt, Morocco, Indonesia, etc, and get good feedback.

Our main products include wood log debarker, veneer peeling machine, vacuum veneer stacker, veneer dryer machine, plywood cold press machine, plywood hot press machine, glue spreader, glue mixing machine, automatic plywood veneer paving line, sanding machine.

With high efficiency sales team offer 24 hours online service, the professional technical team and after-sales service team offer plant layout, machine drawings, and after-sales service.

Choose us, you need not worry anything, we will help you arrange all.

we will offer you the better and suitable machine, two years warranty, professional technical team at your service anytime. and hope that build a good and long-time cooperation.

Clients:

With our clients, we not just partners, we are friends, we will always think about problem standing your position. help you choose the suitable and good plywood machine, help you save cost, and create much benefits.

We not pursue one time cooperation, what we want is building a good and long relationship with you, always support you.

Contacts:

The core composer machine is one of the main equipment for the production of blockboard (large core boards), plywood panel. Through extrusion, heating and other processes to make a full size solid core plywood board equipment, the core composing machine is mainly composed of hydraulic system, pneumatic system and so on.

The core veneer composing line consists of five parts: the board machine host, the high-frequency generator, the hydraulic station, the feeder and the automatic stacker, and the control system. The core composer is controlled by PLC and has the characteristics of high degree of automation, simple and convenient operation, low labor intensity, short splicing cycle, and labor saving. The splicing size of the panel machine is usually 1250*2500mm, and the veneer thickness from 0.8mm to 5mm. When the user has special requirements, a customized configuration design can be made in advance. The equipment adopts high-frequency heating, which can quickly cure the glue in a very short time. The whole working process takes about 3-5 minutes.

Whatsapp: +8618769900191 +8615589105786 +8615805493072

Email: minghungmachinery@gmail.com

Website: www.plywoodmachineline.com