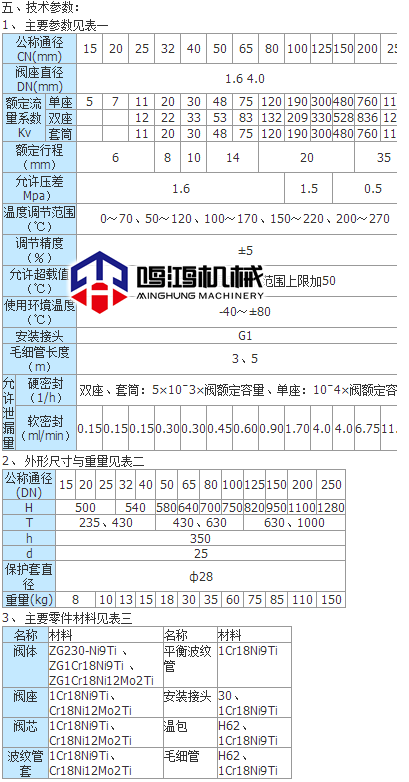

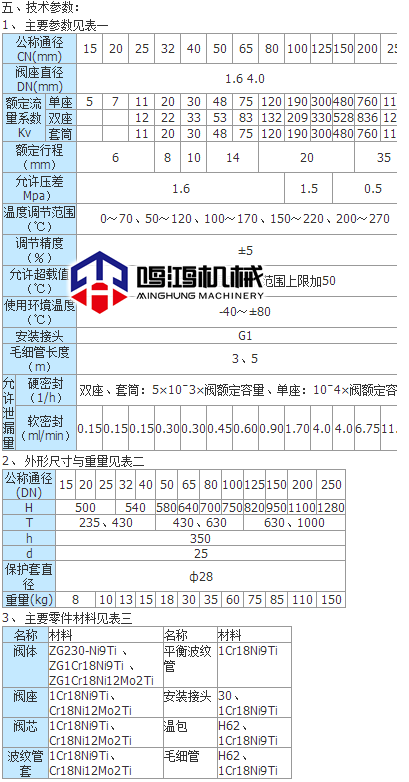

MINGHUNG electric temperature control valve connection size and standard:

Flange standard: cast iron flange according to GB4216-84, cast iron flange according to GB9113-88

Flange sealing surface type: PN10, PN16 are convex

PN40 and PN64 are concave and convex, and the valve body is concave

Structure length: GB12221-89

Jacket heat preservation type jacket heat carrier interface: butt welding φ18×4

The valve body flange and the distance between the flange end faces can be manufactured according to specified standards. Such as ANSI, JIS, DIN and other standards

The bZZW type self-operated temperature regulating valve does not require external energy, and is an actuator product that uses the energy of the adjusted medium to realize automatic temperature adjustment. Nominal pressure PN16, 40, 64; temperature adjustment range from 0~270℃; temperature controller connection joint is G1 external thread; flange standard: PN16, 40 according to BG9113-8; PN64 according to JB79.2-94; PN16 is convex Flange; PN40 and 64 are concave and convex flanges, and the valve body is concave. The structure length is in accordance with the GB12221-89 standard.

The self-operated temperature control valve has a wide range of structures, including ZZWP, ZZWM single-seat and sleeve control valves.

There are two options for heating regulation (B type) and cooling regulation (K type).

It has a wide temperature setting range and is easy to adjust.

There are over-temperature and overload protection measures, safe and reliable.

The temperature setting is convenient, and it can be set continuously during operation.

ZZWPE self-operated electronically controlled temperature regulating valve (applicable to larger diameter and heat transfer oil control). The biggest feature of this valve only requires an ordinary 220V power supply. It uses the energy of the regulated medium to directly react to steam, hot gas, hot oil and gas, etc. The temperature of the medium is automatically adjusted and controlled, and it can also be used to prevent overheating or heat exchange.

ZZWP type self-operated temperature regulating valve does not need external energy to adjust the temperature automatically. It is suitable for various processes and heat exchange and cooling conditions with steam, hot water, hot oil, cooling water, etc. as the medium. The series of products include heating type (B type), cooling type (K type) and three-way confluence or Shunt type (Q/X type). This product is widely used in heating, air conditioning, domestic hot water temperature automatic adjustment, and special working conditions such as petroleum, chemical, textile, pharmaceutical, food and other production projects.

Product name: Electric temperature control valve

Product features: electric temperature control valve (applicable to large and small diameter and steam temperature control), the characteristics of this temperature control valve only need ordinary 220V power supply, using the energy of the medium to be adjusted, directly to steam, hot gas, hot oil and gas, etc. The temperature of the medium is automatically adjusted and controlled, and it can also be used to prevent overheating or heat exchange. The valve has simple structure, easy operation, wide selection of temperature adjustment range, fast response time, reliable sealing performance, and can be carried out at will during operation Therefore, it is widely used in the hot water supply of chemical industry, petroleum, food, textile, hotels and restaurants. Product features: The nominal diameter of this series of products is from 20 to 200mm, the nominal pressure is 1.0, 1.6, 4.0, 6.4MPa, the operating temperature range is from -20 to 350, and the receiving signal is 0 to 10 mA.DC or 4 to 20 mA. DC is used to change the flow rate of the medium to be adjusted to keep the controlled process parameters at a given value. Among them, the single-seat adjustment type is suitable for the occasions where the pressure difference is small, the medium viscosity is large or there is a little particle impurity. Sleeve adjustment type is suitable for large pressure difference occasions.

2. Parts and materials:

Valve body, valve cover: HT200, ZG230-450, ZG1Cr18Ni9Ti

Spool: ZG1Cr18Ni9Ti, Stellite alloy surfacing reinforced polytetrafluoroethylene

Packing: PTFE, flexible graphite

Push rod, bushing: 2Cr13

Gasket: rubber asbestos board, 10, 1Cr18Ni9Ti asbestos spiral wound gasket

Bellows: 1Cr18Ni9Ti

installation matters

Installation, use and maintenance:

(1) Before installation, the pipeline should be in and strictly decontaminated, and the welding slag and other debris should be blown off, otherwise the valve will be seriously damaged.

(2) The temperature control valve should be installed vertically on the horizontal pipeline, and the medium flow direction should be consistent with the arrow on the valve body.

(3) In order to enable continuous operation of the automatic control system or valve maintenance, a bypass valve should be installed, and a filter and pressure gauge should be installed in front of the valve.