what is a boiler

Equipment that uses the heat energy released by fuel combustion or other heat energy to heat water or other working fluids to produce steam, hot water or other working fluids with specified parameters (temperature, pressure) and quality.

A boiler is an energy conversion device. The energy input to the boiler is in the form of chemical energy in the fuel, electric energy, heat energy of high-temperature flue gas, etc., and after the conversion of the boiler, it outputs steam, high-temperature water or organic heat carrier with a heat energy. . The original meaning of the pot refers to the water container heated on the fire, and the furnace refers to the place where fuel is burned. The boiler includes two parts: the pot and the furnace.

The hot water or steam generated in the boiler can directly provide the required thermal energy for industrial production and people's life, and can also be converted into mechanical energy through a steam power device, or converted into electrical energy through a generator. Boilers that provide hot water are called hot water boilers, which are mainly used in daily life, and also have a small amount of application in industrial production. Boilers that generate steam are called steam boilers, often referred to as boilers, and are mostly used in thermal power stations, ships, locomotives, and industrial and mining enterprises

A boiler is a thermal device that uses the heat energy released after fuel combustion or the waste heat in industrial production to transfer to the water in the container to make the water reach the required temperature (hot water) or steam at a certain pressure. It is a complete system consisting of "pot" (that is, the water pressure part of the boiler body, and the heat-absorbing part is called the pot), "furnace" (that is, the part of the combustion equipment, and the part that generates heat is called the furnace), accessory instruments and auxiliary equipment. body. For example, heat-absorbing parts such as water walls, superheaters, and economizers can be regarded as pots; while furnaces, burners, fuel pumps, and draft fans can be regarded as furnaces.

The boiler is operated in two parts of the "pot" and "furnace" at the same time. After the water enters the boiler, the heating surface of the boiler in the steam-water system transfers the absorbed heat to the water, so that the water is heated into hot water at a certain temperature and pressure or steam is drawn out. application. In the part of the combustion equipment, the combustion of the fuel continuously releases heat. The high-temperature flue gas generated by the combustion transfers the heat to the heating surface of the boiler through heat transmission, and the temperature itself gradually decreases, and finally it is discharged from the chimney.

whatsapp: +8618769900191 +8615589105786 +8615805493072

website: www.plywoodmachineline.com

email: minghungmachinery@gmail.com

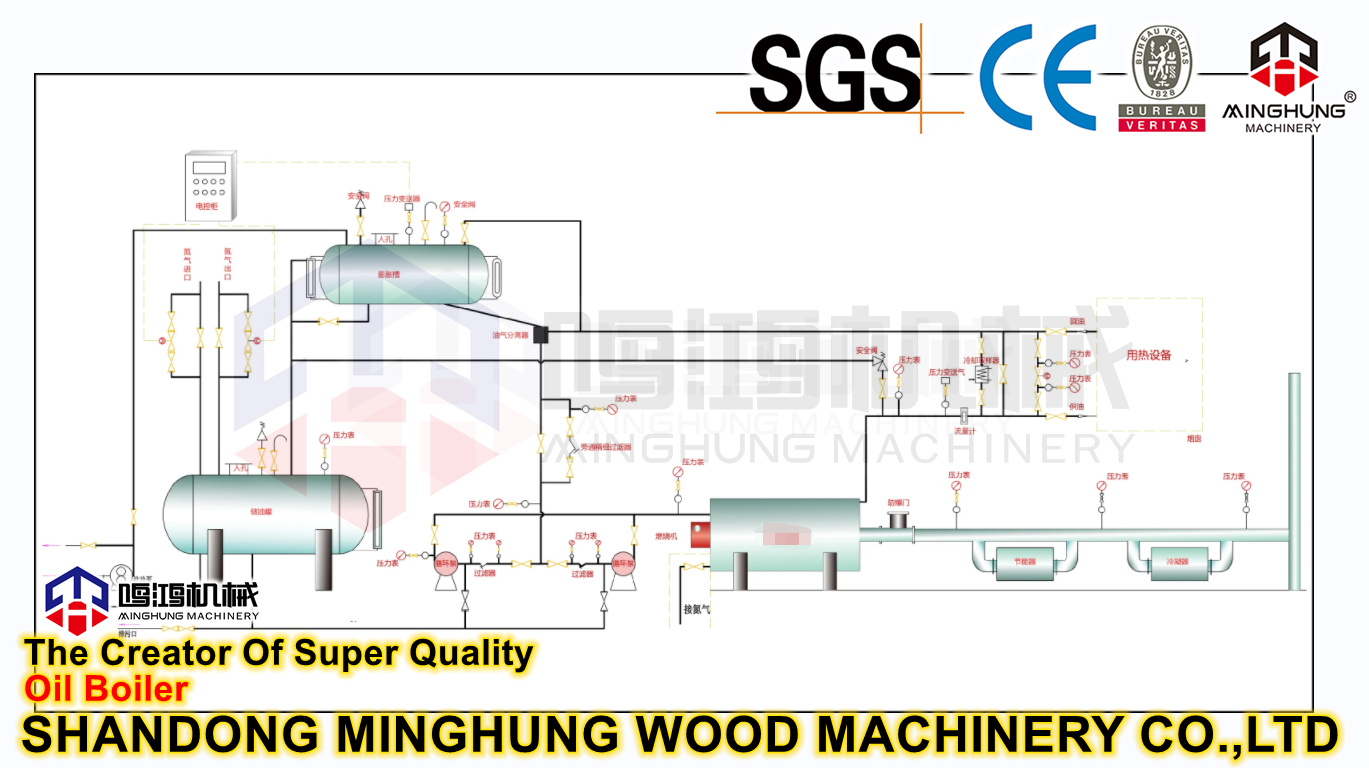

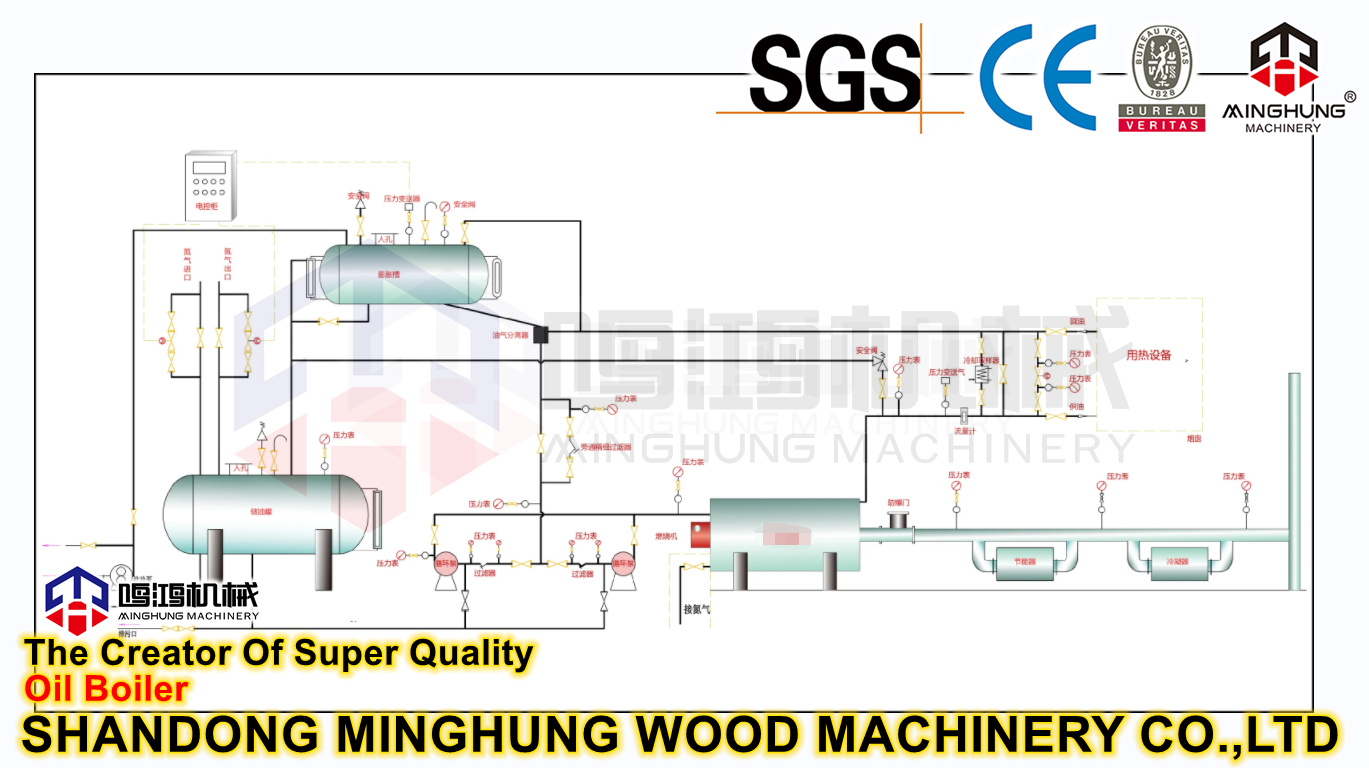

The main working process of the boiler:

1) Fuel combustion process: layer combustion: coal → coal scuttle → grate - (complete combustion) → high temperature flue gas

2) Heat transfer process from flue gas to working medium: high temperature flue gas—(radiation) → water wall—(radiation convection) → slag pipe—(radiation convection) → superheating and reheating pipe—(convection) → economizer—( Dust removal and desulfurization) → low temperature flue gas is discharged to the atmosphere

3) Heating and vaporization process of working fluid: feed water (system water supply water) → feed water tank → pump → economizer → drum—(downcomer) → lower header → water wall tube bundle—(radiation convection steam-water mixture) → separation device→saturated steam→superheater→superheated steam→user

Parameters are the main indicators of boiler performance, including boiler capacity, steam pressure, steam temperature, feed water temperature, etc.

Boiler capacity can be expressed by rated evaporation or maximum continuous evaporation. The rated evaporation is the amount of steam produced continuously per unit time under the specified outlet pressure, temperature and efficiency. The maximum continuous evaporation capacity is the maximum continuous steam production per unit time under the specified outlet pressure and temperature.

Steam parameters include the steam pressure and temperature of the boiler, usually refers to the superheated steam pressure and temperature at the outlet of the superheater and reheater, if there is no superheater and reheater, it refers to the saturated steam pressure and temperature at the outlet of the boiler. The feed water temperature refers to the inlet water temperature of the economizer, and refers to the drum inlet water temperature when there is no economizer.

Boiler capacity refers to the ability of a boiler to provide heat. The larger the capacity, the larger the heating capacity and the larger the output; otherwise, the smaller the output. For example, a steam boiler with a capacity of 1t/h means that the boiler can turn 1 ton of water into saturated steam under a certain pressure within 1 hour. Working pressure Working pressure refers to the maximum allowable pressure of the boiler. The working pressure is determined according to the design pressure, usually expressed in MPa.

Boiler pressure Boiler pressure (pressure) commonly referred to in the boiler industry is the force perpendicular to the unit wall area of the container, expressed in "Mpa", and the old unit is "kgf/cm2" (kgf/cm2).

Rated temperature The temperature indicated on the nameplate of the boiler is the temperature of the medium at the outlet of the boiler, also known as the rated temperature. Evaporation (D) When the steam boiler operates safely for a long time, the amount of steam produced per hour, that is, the evaporation of the boiler, is expressed by "D", and the unit is ton/hour (t/h).

The water in the saturated steam boiler is heated by the heat released by the fuel combustion under a certain pressure to boil, and vaporizes into steam. The temperature of the boiler water in the boiling state is saturated steam; just high. Such as 1.0 Mpa saturated steam temperature 184 ℃, 1.25 Mpa saturated steam temperature 193 ℃.

Superheated steam The steam whose temperature is higher than the saturation temperature under the corresponding pressure is called superheated steam. Superheated steam has a large heat enthalpy, high entropy value and great work ability. Superheated steam with the same quality as saturated steam is used as a heat source, which can increase the temperature of the heated medium, and when it is fed into the turbogenerator, it can emit more energy. electricity.

Thermal power (heat supply Q) When the hot water boiler operates safely for a long time, the output water can effectively carry heat per hour. That is, the thermal power of a boiler, represented by "Q", the unit is megawatt (MW), and the engineering unit is 104 kcal/hour (104Kcal/h).

Boiler thermal efficiency refers to the percentage of heat absorbed by water, steam or heat transfer oil during the heat transfer process of the boiler or organic heat carrier furnace, accounting for the heat released by the complete combustion of the fuel entering the boiler. Water vapor system In terms of water vapor system, after the feed water is heated to a certain temperature in the heater, it enters the economizer through the feed water pipe, and after further heating, it is sent to the drum, mixed with the pot water, and then goes down the downcomer to the inlet header of the water wall. The water absorbs the radiant heat of the furnace in the water-cooled wall tube to form a steam-water mixture through the riser tube and reaches the drum, and the steam-water separation device separates the water and steam. The separated saturated steam flows from the upper part of the drum to the superheater, and continues to absorb heat to become superheated steam at a certain temperature (currently, the steam temperature of most 300MW and 600MW units is about 540°C), and then sent to the steam turbine.

Combustion and flue air system In terms of combustion and flue air system, the blower sends air into the air preheater to be heated to a certain temperature. The coal powder that is ground into a certain fineness in the coal mill is carried by a part of the hot air from the air preheater and sprayed into the furnace through the burner. The mixture of pulverized coal and air ejected from the burner is mixed with the rest of the hot air in the furnace and burned, releasing a lot of heat. The hot flue gas after combustion flows through the furnace, slag tube bundle, superheater, economizer and air preheater in sequence, then passes through the dust removal device to remove the fly ash, and finally is sent to the chimney by the induced draft fan to be discharged to the atmosphere . Fuel Fuels for industrial boilers are divided into three categories: solid fuels—bituminous coal, anthracite, lignite, peat, oil shale, wood chips, bagasse, rice bran, etc.; liquid fuels—heavy oil, residual oil, diesel oil, etc.; gas fuels—natural gas , artificial gas, liquefied petroleum gas, etc.

Composition and properties of coal

Composition: C.H.O.N.S.A.W High calorific value Q high refers to the heat released when the combustion product is cooled to the point where the water vapor in it is condensed into water at 0 degrees after the complete combustion of 1KG fuel.

Low calorific value Q low refers to the heat obtained by removing the latent heat of vaporization from the combustion products after the complete combustion of 1KG fuel. The reason why the boiler design adopts low calorific value: After the coal is burned, the exhaust smoke still has a relatively high temperature, so that the steam cannot be condensed, and the latent heat of vaporization cannot be recycled, so the low calorific value is adopted. When the air is isolated and heated above 850°C, organic matter and minerals will decompose, and the gaseous products released from the decomposition are called volatile matter. Coal with a lot of volatile content is easy to catch fire and burn out; Applied composition: C%+H%+O%+N%+S%+A%+W%=100% Dry composition: C%+H%+O%+ N%+S%+A%=100% Combustible components: C%+H%+O%+N%+S%=100%

More about boiler contact us:

whatsapp: +8618769900191 +8615589105786 +8615805493072

website: www.plywoodmachineline.com

email: minghungmachinery@gmail.com