Veneer Production Process Step -Veneer Production Peeling Line for Hard wood

Do you know how to produce wood veneer? what is the production step for making veneers?

Follow me and watch the production steps

For making wood veneer, first you need have log, according to your local market demands and wood resource, you can choose the suitable wood. Different country clients will use different wood, some use poplar, some use beech and birch, some use pine, some use ecalyptus and so on.

Then, you need the Veneer making machine.

One completely line of Veneer making machine includes: Log debarker, Rotary veneer peeling machine, Log loader, and Automatic stacker. With these machines, you can start to produce veneer sheets.

Now let me introduce each machine one by one for you

Log debarker

Log debarker is the first step of the whole veneer production line. Its function for peel off wood barks, also make wood shape become round. It need one worker to operate the handle shank, move it forward and backward to rotary peel the wood.

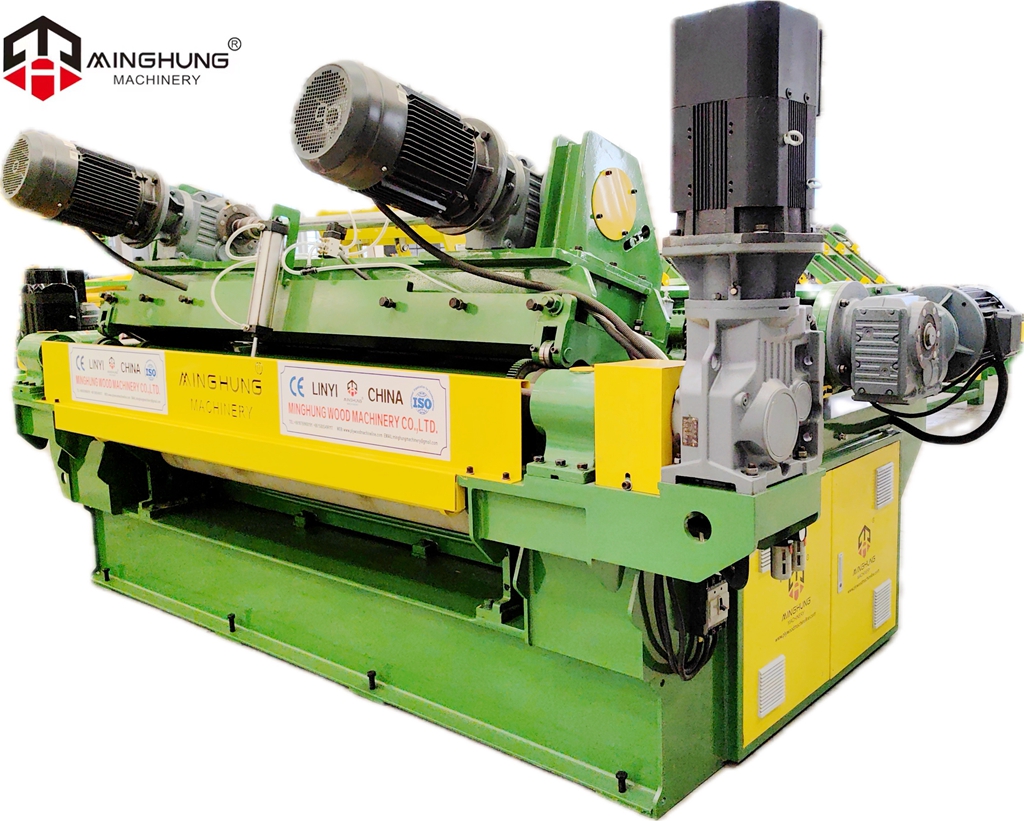

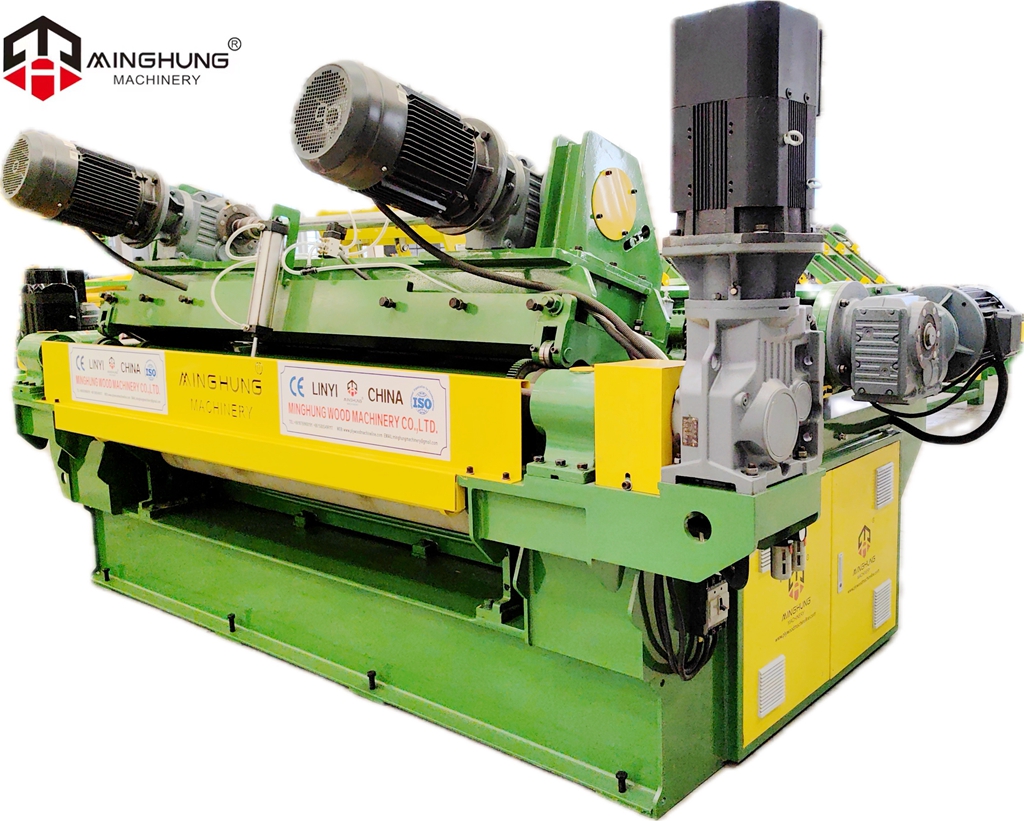

Rotary peeling machine

Rotary peeling machine plays a very important role of the whole peeling line. It will peel and produce veneers by rotate peeling wood. Usually the Veneer peeling machine includes veneer cutting knife too, so it will directly make wood veneer and cut it to be required width.

You can set the veneer thickness and cutting width from cnc screen, then you will get the veneers which you need.

Veneer peeling machine can be different specification as different clients requires. For us, now we mainly offer our strong and high specification type. So you can peel kinds of hard wood.

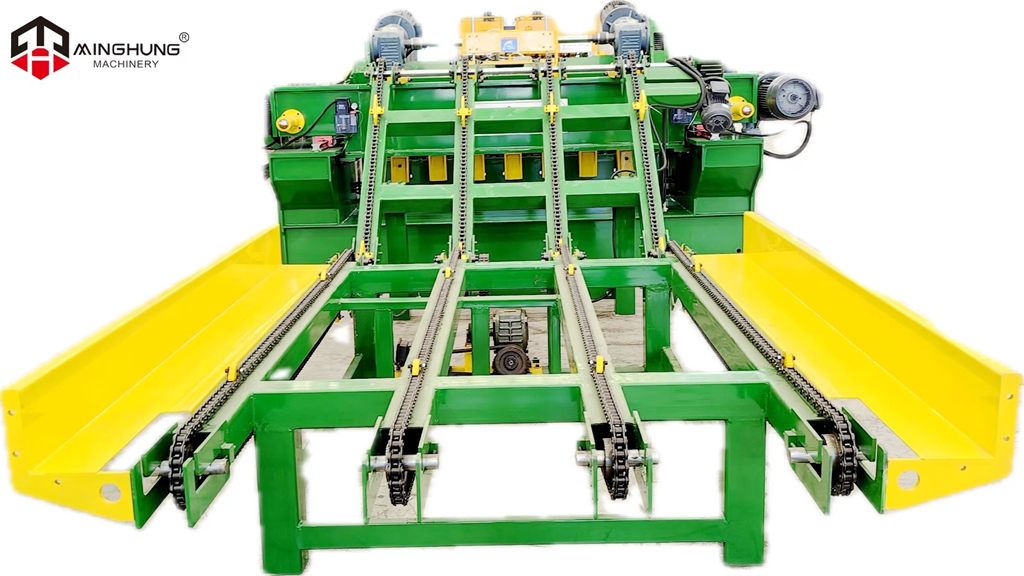

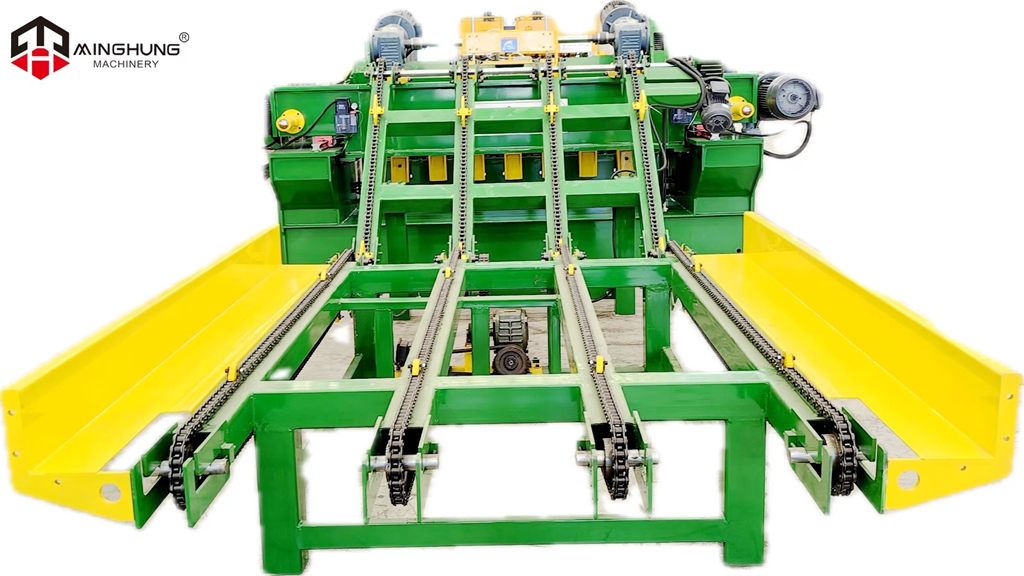

Log loader

One veneer production line includes 2pcs log loader, one for automatic convey wood into Debarker, another one for automatic convey wood into Veneer lathe.

Veneer stacker

With this stacker, it can automatic stacking the peeled veneers, instead two workers. So it will improve the work efficiency and production capacity.

Until now, with above machines, you can start to produce wood veneers.

Above machines, are also necessary for making veneers

Knife grinder

Knife grinder is simple structure, but it also very important. Its function for grinding peeling knife, make it sharp again. As we know, knife quality also important for veneer machine.

It can be different length as your peeling knife length

Veneer drying machine

Dryer for drying the peeled original veneer moisture. different wood species, its water content are different, usually between 40-70%, so the peeld veneer moisture is also high, such high moisture is impossible for making final product. This is why veneer dryer is required.

Veneer drying machine has Roller dryer and Mesh dryer, they can be designed to be different width, length and decks, to satisfy different drying capacity and clients requires.

Ok, now with these machines, you can produce veneers

Good machine will be very helpful for making wood veneers. And if you use veneer to produce plywood, then its quality will directly affect the plywood quality.

For our factory, we have specialize in manufacturing woodworking plywood machinery many years, we have rich production experience, advanced production lathes, experienced and professional workers and engineers, and fast good after sales service, and our factory keep to improve our machines every year, and insist use good materials and spare parts, to ensure our machine is very good and strong, which will help our customers business going better and better.

Glue spreading machine

Veneer core composer

Cold press machine

Hot press machine

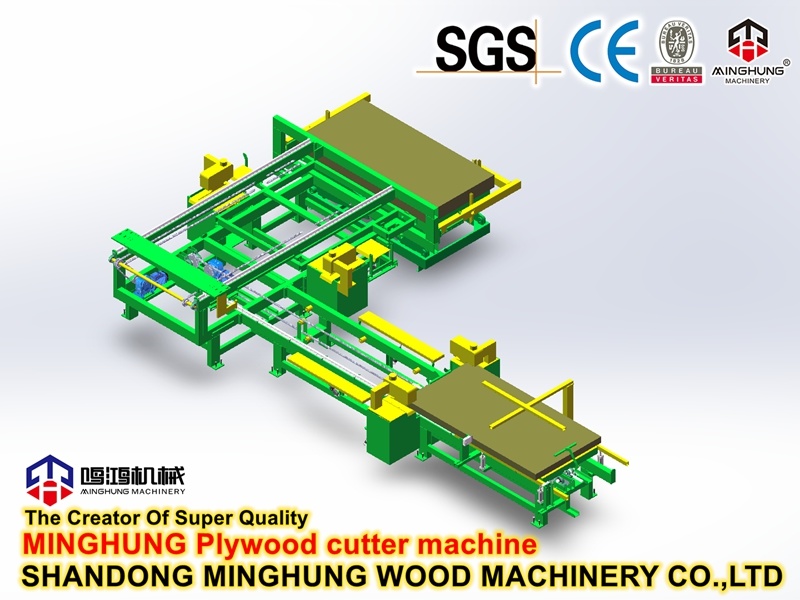

Plywood cutting machine

Machines such as glue mixer, glue spreading machine, veneer core composer, plywood putty machine, cold press machine, hot press machine, plywood cutting machine, sanding machine and calibrating machine, lift table, film faced plywood hot press machine, and so on, our factory manufacture all of them.

If you need related machines, welcome contact us, we will quickly reply and offer more information for you

Contacts:

Mark: +86 18769900191

Ali: +86 15805496117

Lucinda: +86 15805493072

Email: minghungmachinery@gmail.com