Stage 1: Log Handling & Block Preparation

Log Receiving & Storage:

Process: Logs are transported to the site by truck or rail and unloaded into the log yard. Sprinkler systems are used for maintenance to prevent cracking and deterioration.

Key Equipment: Gantry cranes, loaders, log debarkers, sprinkler systems.

Note: The log yard requires a hardened ground surface and a well-designed drainage system.

Log Bucking/Cutting:

Process: Logs are cross-cut into specific lengths (blocks) according to the core and face veneer sizes required by customer orders.

Key Equipment: Large gantry saws or band saws, often equipped with automatic diameter scanning and optimization systems to maximize yield.

Block Conditioning (Heating) & Debarking:

Process: Blocks are heated in hot water vats (or steam chambers) to soften the wood, facilitating the peeling of high-quality, defect-free veneer. This is followed by mechanical debarking.

Key Equipment: Hot water vats (or steam chambers), debarkers, discharge units.

Stage 2: Veneer Production

Veneer Peeling:

Process: This is the core operation. The conditioned block is mounted on a lathe and rotated against a blade, peeling a continuous ribbon of veneer.

Key Equipment:CNC spindleless peeling lathe (Standard for modern plants, automatically adjusts to block diameter, offers high yield and precise thickness).

Veneer Clipping & Conveying:

Process: The continuous veneer ribbon is conveyed to a clipper, which cuts it into rectangular sheets according to set dimensions.

Key Equipment: Roller conveyors, precision clippers.

Veneer Drying:

Process: Green veneer has very high moisture content and must be dried to a suitable level (typically 6%-12%) before gluing and pressing.

Key Equipment:Roller dryer (Mainstream choice, high efficiency) or mesh belt dryer. Modern dryers use intelligent temperature control systems for energy efficiency.

Veneer Sorting & Patching:

Process: Dried veneer sheets are sorted according to defect grades. High-grade face veneer requires patching (e.g., plugging, stitching).

Key Equipment: Veneer sorting lines, veneer stitchers, plugging machines.

Stage 3: Plywood Forming

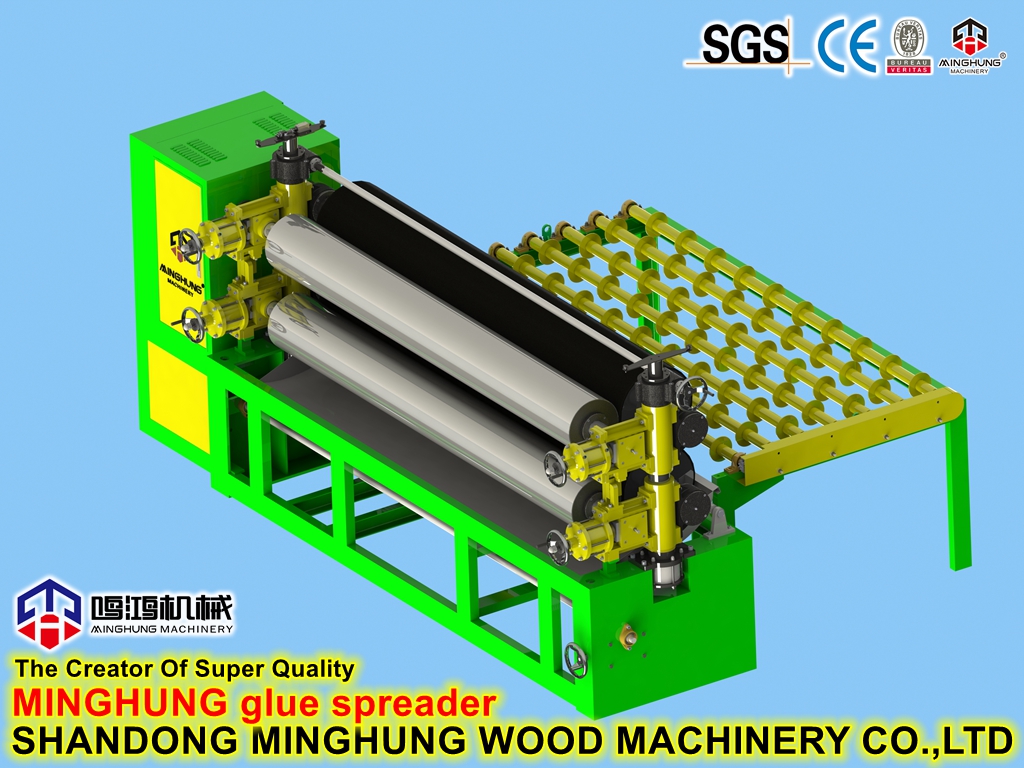

Gluing & Layup:

Process: Prepared adhesive (e.g., Urea-Formaldehyde UF, Phenol-Formaldehyde PF, Soy-based glue) is applied evenly to the core veneers. The veneers are then laid up layer by layer (face-core-back) to form a panel mat.

Key Equipment:Roll-type Glue spreader (roller or curtain type), automatic layup line (Core of modern automated plants, uses robots or assembly stations for efficient and precise layup).

Cold Pre-pressing:

Process: The laid-up mat is sent through a cold press for initial consolidation, allowing the layers to bond slightly for easier handling and loading into the hot press.

Key Equipment: Cold press.

Hot Pressing:

Process: The core forming operation. Under high temperature and pressure, the adhesive cures, firmly bonding the multiple veneer layers into plywood.

Key Equipment:Multi-opening hot press (High capacity) or continuous flat press (Extremely high efficiency, suitable for very large scale production). Auxiliary equipment includes loaders, unloaders, hydraulic systems, heating systems (thermal oil boiler or steam boiler).

Stage 4: Finishing & Packaging

Trimming & Sanding:

Process: The rough-edged pressed panels are trimmed to standard sizes by cross-cut and edge saws. They are then sanded to achieve uniform thickness and a smooth surface.

Key Equipment: Dual-trimmer saws (cross-cut and edge), wide-belt sanders (typically a combination of roughing and finishing sanders).

cross-cut saw

sander

Grading & Inspection:

Process: Finished panels are inspected and graded according to appearance and quality standards (e.g., GB/T 9846, ASTM, EN).

Key Equipment: Inspection tables, thickness gauges, moisture meters.

Packaging & Storage:

Process: Qualified products are labeled, strapped, and packaged with waterproof film or in cartons. Finally, they are moved to the finished product warehouse by forklift.

Key Equipment: Automatic strapping machines, stretch wrapping machines, forklifts.