Keywords:

#plywoodmachine #woodworkingmachine #plywoodmanufacturing #plywoodproduction #hotpress #Chinafactory #manufacturer

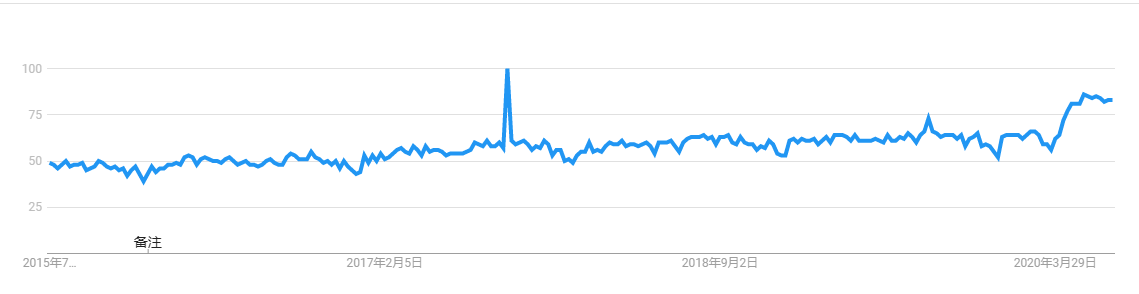

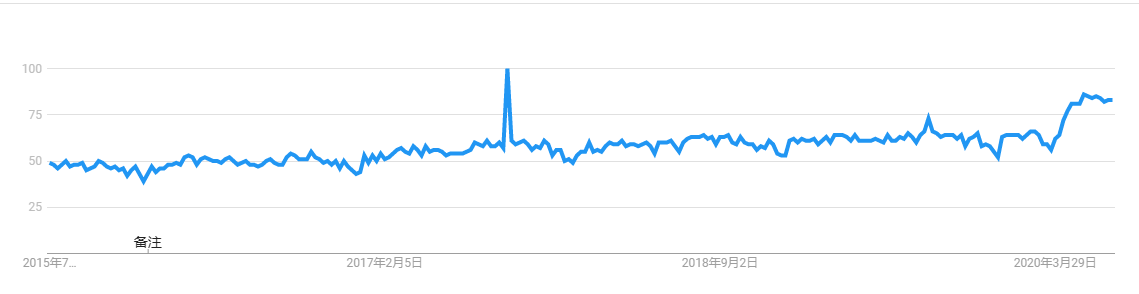

For the last five years, the plywood trends still keep popular search, Plywood is a wood panel prepared from thin sheets of wood veneer core, pasted together using an adhesive to create a panel equally strong or stronger than wood.It is strong, flexible, re-usable and workable and durable. Plywood is used as a substitute to the wood boards due to its resistance to crackling, shrinkage and twisting. Moreover, plywood uses adhesive to bind the veneers which make it water resistant. These types of veneers are suitable for exterior use such as sheds and marine construction.

plywood processing

The plywood is used in the construction of marine decks making it suitable for use by the structural panel market. Further, it has its uses in the construction of light partition or external walls, furniture particularly in cupboards, kitchen cabinets and light doors and shuttles. Likewise, plywood is also used in the commercial constructions for temporary flooring, detached garages and sheds. Moreover, the softwood plywood is used beyond construction of homes and is used in wide range of activities including skateboard ramps and work tables.

The most common sizes in plywood are 4’ x 8’, 4’ x 6’, 4’ x 10’, 3’ x 6’. Throughout the forecast period, the 4’ x 8’ size plywood segment is anticipated to maintain its dominance in the global market as these plywood lead to minimum wood wastage in downstream applications, making them the most economical size among all sizes.

Plywood has different sizes, different thicknesses are available in plywood. Based on thickness, the market can be categorized into < 8mm thickness, 8mm – 18mm thickness, and > 18mm thickness segments. It is proven fact that a thicker plywood offers higher mechanical stability and dimensional stability. Therefore, plywood thickness greater than 18mm are generally preferred in high load bearing applications while 8mm – 18mm thick plywood are significantly consumed during the manufacturing of furniture. Globally as well as regionally, the > 18mm thickness segment is anticipated to remain dominant throughout the forecast period. The common plywood thickness is 18mm.

So if you wants to start produce plywood, it is still good time. And how to start this new business? What kinds of woodworking machine do you need? as we know, wood veneer is the material for making plywood, and wood veneer produced from wood log.

as we know, wood veneer is the material for making plywood, and wood veneer produced from wood log.

So, logs are the original materials. Different area will use different logs according to their resounces. For example, in Turkey, many people use Beech, poplar. In Indonesia, many people use Albasia, in Bulgaria, people use Beech Birch, in Russia, many people use beech. So you can choose one according to your market.

This need wood debarking machine and veneer peeling machine, the former for removing wood bark, and make log round, the latter for peeling wood into pieces of wood veneer/wood foil. According to your wood is softwood or hardwood, and the log diameter, length, and thickness you require, the veneer machine will be different, for example, the veneer machine can be 4feet(max log length 1300mm), or 8feet (max log length 2600mm). or veneer machine can customize according to your needs.

After producing wood veneer, you can choose manually receive wood veneer, or choose vacuum veneer stacker to automatic sorting wood veneer, this will save time and improve work efficiency.

The next steps for making plywood

>>>because the veneer humidity is high, only drying it into suitable humidity, can make plywood, so put veneer on veneer dryer machine, the end humidity will be about 10%, and this is fine to make plywood. Veneer dryer machine has three types, they are veneer press dryer, veneer roller dryer, veneer mesh dryer, according to your production capacity, veneer thickness, factory room, budget..to choose the suitable one for you.

>>> wear glue on the surface of wood veneer by glue spreader, then workers lay them out into plywood size, you can choose manually, or using plywood veneer paving line/assembly line/lay out machine.

>>> put the lay out plywood into plywood cold press machine, for pre-pressing plywood. Cold press’s pressure can be 400t, 500t, 600t, structure is easy and operate is easy too.plywood press machine plywood pre press machine plywood cold press machine

>>>then put plywood into hot press machine, for pressing plywood into one strong and durable board. In general, 15layers 500t hot press is popular, but if you will laminate melamine on plywood, 500t is not enough, better 10layers 800t hot press, this will be very nice. Of course, if you want to bigger pressure, or others layers like 20layers, 25layers, also no problem. Because the hot press not one type, they always be produced according to every customer’s requires.

>>> because until this step, the plywood four sides are rough, so need be trimmed by plywood edge cutting saw machine, the plywood will become tidiness, and all board width and length are same. The plywood trimming saw machine be guide by infrared, be controlled by micro-computer, high efficiency and very fast.

>>> for making good and high quality plywood, need plywood sander sanding plywood, because the thickness in one same plywood may be different, but after sanding them, the thckness will be accurate and evenly. And at the same time, the surface of plywood will become smooth. Sanding machine has different types, it can be 1 head, 2 heads, 3 heads, it can be light weight and heavy duty, it can be single side and double sides, it can mainly for calibrating thickness, it also can mainly for polishing the surface. So tell your requires about the plywood, then you will get the suitable plywood sanding machine.

Until now, the plywood manufacturing process finish, so if you want to produce plywood, you need the whole plywood machine. Each step is important and necessary.

If you are interested or wants to know more about plywood machine, welcome contact me, i can share the videos of plywood machine with you.

Who we are?

We are China factory which produce plywood machine and veneer machine with many years experience, through continuous improvement and development, our factory now has been on the top suppliers in China.

The machines includes: wood log debarker, veneer peeling machine, veneer stacker, veneer dryer machine, plywood veneer paving line, core composer, plywood cold press machine, plywood hot press machine, plywood saw machine, plywood sanding machine, lift table.

Our principle is offer good plywood machine to our clients, help their business create much value

Contacts:

Whatsapp: lucinda: +86 15805493072 ali: +15589105786 mark: +8618769900191

Email: makeminghung@gmail.com garysinghco@gmail.com minghungmachinery@gmail.com

as we know, wood veneer is the material for making plywood, and wood veneer produced from wood log.

as we know, wood veneer is the material for making plywood, and wood veneer produced from wood log.