Our "Non-destructive Drying Plywood Drying System" is an advanced drying solution specifically designed for the production of high-quality plywood and wood-based panels. Utilizing innovative low-temperature dehumidification and precise air circulation technology, the system efficiently removes moisture from within the wood while strictly controlling temperature and humidity. This fundamentally prevents common damages associated with traditional drying methods, such as cracking, warping, and internal stress.

The core advantage lies in its "Non-destructive" capability. The gentle and uniform drying process preserves the wood's natural strength, flatness, and structural integrity to the greatest extent, significantly enhancing the grade and value of the finished plywood. Equipped with intelligent fully-automatic controls, the system is energy-efficient and allows for customized drying programs based on wood species, thickness, and initial moisture content, ensuring stable and repeatable high-quality drying outcomes.

1. Low-Temperature Dehumidification Cycle:

The system operates at relatively low temperatures (typically 30-55°C). Fans drive air to circulate uniformly within the drying kiln and through the wood stacks.

Warm, humid air passes through a rotary or fixed desiccant wheel/condensation unit, where moisture is efficiently adsorbed or condensed and removed.

The dehumidified air, with significantly lowered relative humidity and enhanced moisture absorption capacity, is slightly reheated and returned to the kiln to absorb moisture from the wood.

This cycle repeats, steadily reducing the wood's moisture content without subjecting it to thermal shock.

2. Precise Environmental Control:

The system integrates high-precision temperature and humidity sensors and wood moisture content monitoring probes to monitor the kiln climate and the core state of the wood in real-time.

The PLC intelligent control system automatically adjusts heating power, dehumidifier operation, fan speed, and fresh air/recirculation air ratio based on preset drying schedules or AI-optimized algorithms.

This ensures that the temperature and humidity gradient changes throughout all drying stages (preheating, constant rate drying, falling rate drying, final conditioning) perfectly adapt to the drying characteristics of the specific wood, achieving "gentle" drying.

Component | Functional Description |

Insulated Drying Kiln Body | Constructed with sandwich color steel plates or stainless steel plates, filled with high-performance insulation material (e.g., polyurethane), ensuring minimal heat loss and excellent airtightness. |

Heating System | Typically uses efficient electric heating, hot water/steam heat exchangers, or heat pump auxiliary heating to provide a clean, controllable heat source. |

Dehumidification Unit | The core of the system, containing a desiccant wheel (adsorption type) or a compression refrigeration unit (condensation type), responsible for extracting moisture from the air. |

Air Circulation Fan System | High-power, low-noise axial or centrifugal fans ensure air moves through each layer of panels at a uniform speed and pressure, eliminating dead spots. |

Intelligent Control System | PLC + touchscreen HMI, capable of storing multiple drying schedules, enabling fully automatic operation, remote monitoring, fault alarms, and data logging. |

Loading Carts & Tracks | For carrying and transferring panel stacks, improving loading/unloading efficiency (optional depending on configuration). |

1. Loading & Inspection: Wet panels stacked according to specifications are loaded into the drying kiln, and moisture content probes are installed.

2. Schedule Selection: Select the corresponding wood species, thickness, initial/target moisture content on the control panel, or call up a custom drying schedule.

3. Automatic Operation:

Preheating Stage: The system heats up to the set point, uniformly warming the entire wood mass without intense dehumidification.

Main Drying Stage: Based on real-time monitoring data, the system automatically executes precise control of "heating-dehumidification-circulation" to gradually reduce moisture content.

Final Conditioning: At the end of drying, temperature and humidity are adjusted to balance stress between the interior and surface of the panels, relieving residual stress and improving dimensional stability.

4. Unloading & Stabilization: Once the target moisture content (typically 8%-12%) is reached, the system shuts down automatically. Panels are stabilized inside the kiln or in a storage environment before use.

Drying of core veneers for plywood.

Drying of face and back veneers for furniture and decoration.

Drying of plywood for concrete formwork.

Drying of substrates for blockboard and eco-friendly boards.

Drying of other special wood-based panels requiring high flatness and stability.

Kiln Capacity: From 10m³ to 200m³ or custom.

Max. Panel Size: Width ≤ 1300mm, Length ≤ 2500mm (customizable).

Target Moisture Content: 8% - 12% (adjustable).

Drying Temperature Range: 30°C ~ 65°C.

Control System: PLC + Color Touchscreen, supports remote monitoring.

Heating Method: Electric Heating / Heat Pump / Steam Heat Exchanger (optional).

Installed Power: Varies by capacity, ranging from 15kW to 150kW.

The Non-destructive Drying Plywood Drying System represents the development direction of modern wood drying technology. Through precise, gentle, and intelligent drying methods, it perfectly solves the industry pain point of balancing efficiency and quality. It is an ideal choice for plywood manufacturing enterprises aiming for capacity upgrading, quality breakthrough, and green manufacturing.

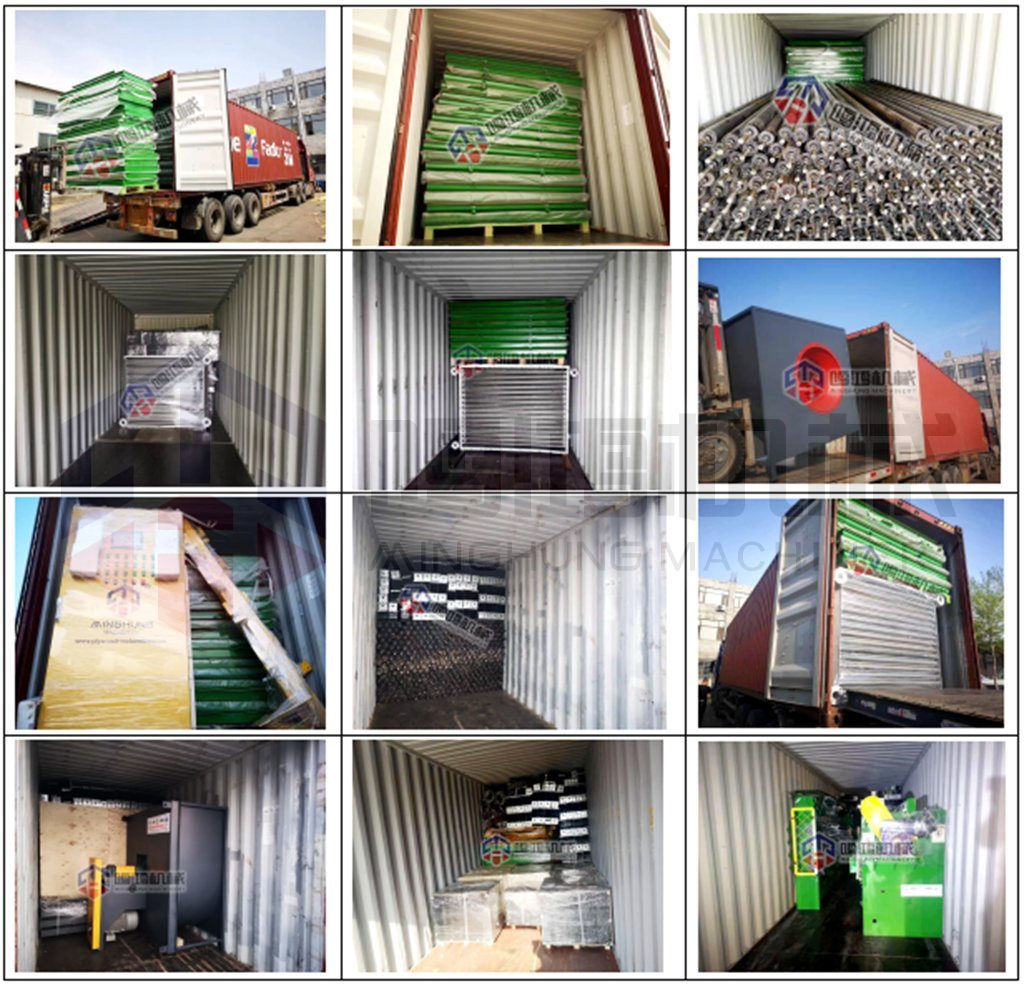

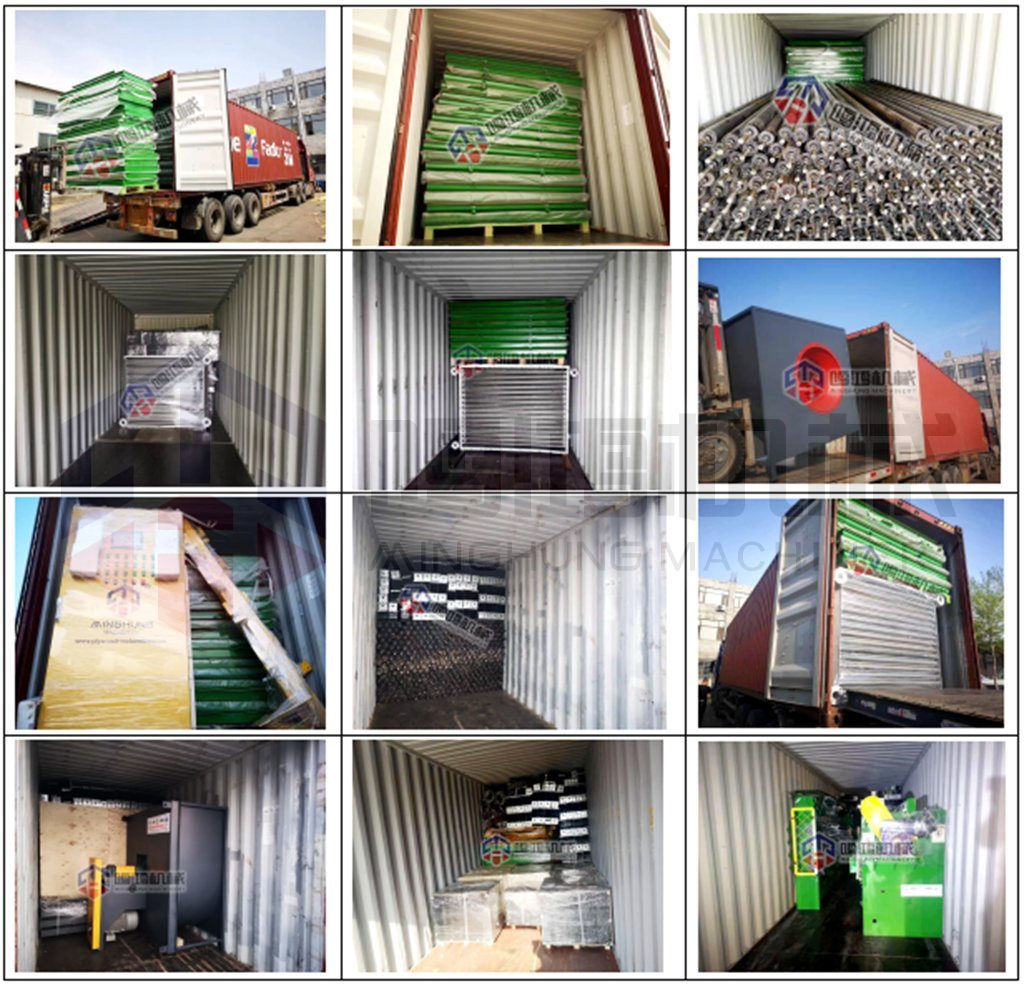

We maintain a long-term cooperation with a well-known freight forwarding company, and adhere to the customer-first philosophy. We strictly implement the quality inspection process before shipment to ensure that each batch of products meets international quality standards, We deeply understand that high-quality service is the cornerstone of winning customer trust, and we always create value for customers with professional and efficient supply chain management.

Global Delivery: Export packaging (wooden case/steel frame) provided, supports CIF/FOB terms, assists with customs clearance documentation.

Installation & Commissioning: Dispatch experienced engineer teams to the customer's factory for installation guidance, equipment commissioning, and trial production.

Technical Training: Comprehensive theoretical and practical training for customer's operators, maintenance, and management staff until they can operate independently.

Warranty Commitment: 12-month warranty for the whole machine, lifelong technical consultation and paid spare parts supply.

Remote Support: 7x24 online technical consultation available, with remote diagnostics and troubleshooting via video call.

We are Shandong MINGHUNG Wood Based Panel Machinery Co.,Ltd China factory and manufacturer of full sets of Plywood machinery and Veneer machinery. With many years production experience, advanced production technology,experienced workers and professional engineers, we can offer you the suitable, good and strong machinery for you.

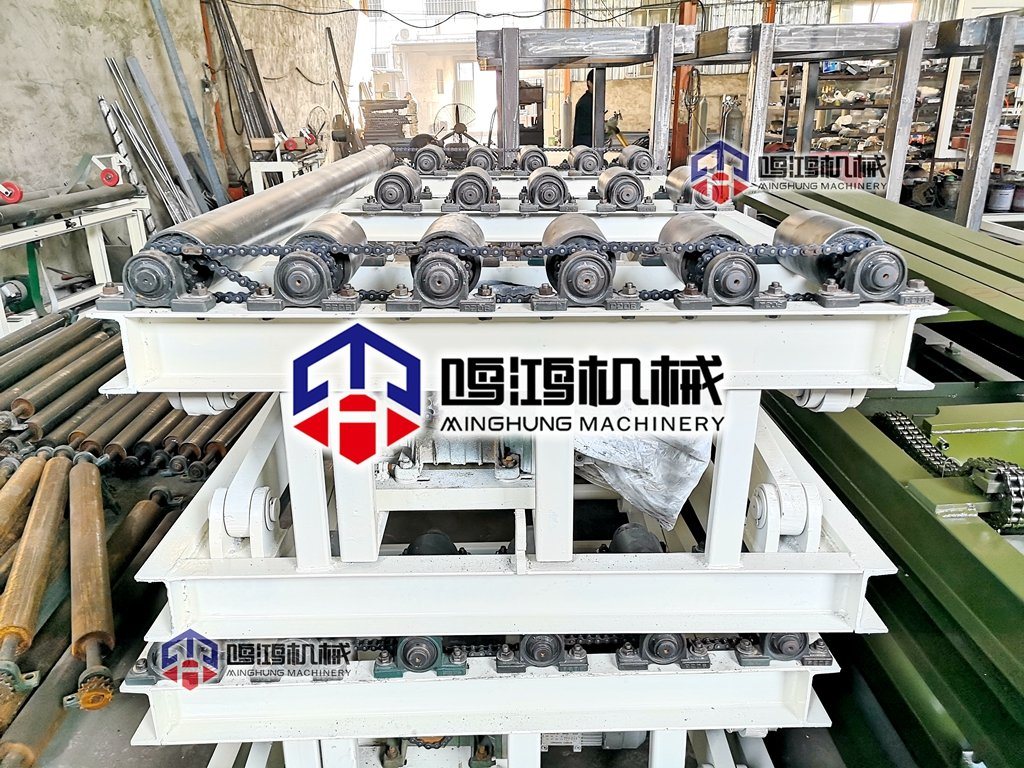

The machinery we produce includes peeling machines, chipping machines, rotary cutting machines, drying machines, gluing mixers, laying machines, pre-pressing machines, hot pressing machines, cooling machines, longitudinal and transverse sawing machines, sanding machines, as well as auxiliary machinery such as automatic feeding and discharging systems and lifting platforms.

Q:How long the production time?

A:If one set machine,3-4 months;If the full production line 6-8 months.

Q:What are your advantages?

A:We have rich experience in the market, with the same cost, we do better because we have strict control of the production process. We have an independent inspection department to check the quality.

Q:Can you customize products for customers?

A:Yes, we can customize products according to customer requirements or drawings. At the same time, we protect customers' business privacy with the strongest awareness.

Q:What payment methods do you offer?

A:Usually T/T and LC. If you have other payment methods, we can also consider it.

Customize Your Plywood Solution Now! Plant layout design, on-site training & global logistics support – Build your competitive plywood brand today!