I. Core Energy-Saving Principles

The high energy consumption of traditional dryers is mainly due to a large amount of heat being lost through exhaust air and steam. Low-energy equipment addresses this through:

1. Heat Recovery Technology (The Core)

How it works: A heat exchanger (e.g., heat pipe, plate, or rotary wheel type) is installed in the exhaust system. The outgoing high-temperature, humid exhaust air and the incoming fresh cold air cross paths in the exchanger without mixing.

Energy Saving: The sensible heat from the exhaust air and latent heat from the steam are efficiently recovered and used to preheat the fresh air entering the drying chamber. This can recover over 60% of the energy from the exhaust, drastically reducing the fuel needed to heat fresh air.

2. Precision Intelligent Control System

How it works: Based on a PLC and touch screen HMI, the system collects real-time data from temperature and humidity sensors throughout the drying chamber. It automatically and precisely adjusts:

Heat output (burner power or steam valve opening)

Exhaust damper opening

Circulation fan speed

Belt speed (i.e., drying time)

Energy Saving: Avoids energy waste from "over-drying" or "under-drying" common in manual operation. The system auto-adjusts to external conditions (day/night, seasons), maintaining peak efficiency.

3. High-Efficiency Insulation & Sealing

How it works: The chamber is constructed with thick high-temperature rock wool or polyurethane insulation to prevent heat loss. All doors and joints are sealed with high-temperature seals to prevent hot air leakage.

Energy Saving: Excellent insulation acts like a "winter coat," keeping heat contained within the chamber for sky-high thermal efficiency.

4. Efficient Heat Source & Aerodynamic System

Heat Source: Priority recommendation for biomass burners, which have far lower fuel costs than gas or oil. Also compatible with steam heat exchangers, thermal oil heaters, etc.

Fans: Use of high-efficiency, low-energy consumption centrifugal fans controlled by Variable Frequency Drives (VFDs). Fan speed adjusts automatically based on drying phase needs, saving substantial electricity.

1. High-Efficiency Air Heater & Multi-Fuel Heat Source System

Function: Provides stable and efficient thermal energy.

Low-Energy Features:

High-Efficiency Burners: Ensure complete fuel combustion.

Multi-Fuel Adaptation: Biomass burners (recommended for lowest cost and sustainability), gas, oil, steam, or thermal oil.

Optimized Heat Exchange: Design maximizes heat transfer surface area, minimizing exhaust gas temperature.

2. Heat Recovery System (Energy-Saving Core)

Function: Recovers energy from hot, humid exhaust air to preheat fresh intake air.

Low-Energy Features:

Heat Exchanger Types: Heat pipe or plate heat exchangers allow non-contact heat transfer, recovering over 60% of waste heat.

Energy Impact: Dramatically reduces the fuel required to heat incoming air.

3. Intelligent Control System (The Brain)

Function: Precisely monitors and controls all drying parameters for "on-demand" energy use.

Low-Energy Features:

PLC + HMI Touchscreen: Central control unit with programmable recipes.

Sensor Network: High-precision temperature and humidity sensors.

Automation: Automatically adjusts burner, exhaust dampers, fan speeds, and belt speed based on real-time data.

Remote Monitoring: Enables optimization and diagnostics.

4. Insulated and Sealed Chamber

Function: Creates an enclosed drying space.

Low-Energy Features:

Thick Insulation: 150mm+ high-temperature rock wool minimizes heat loss.

High-Performance Seals: High-temperature gaskets on all doors and joints prevent heat leakage.

5. Frequency Drive & High-Efficiency Air System

Function: Drives the conveyor and creates air circulation.

Low-Energy Features:

Variable Frequency Drives (VFDs): installed on circulation fans and main drive motors. Adjust motor speed to match exact process needs, reducing electricity consumption by over 40%.

High-Efficiency Centrifugal Fans: Aerodynamically optimized impellers for lower power consumption.

6. Material Handling System

Function: Conveys veneer continuously through the dryer.

Components: Infeed spreader, multi-layer stainless steel mesh belts, chains, drive rollers, outfeed stacker.

7. Moisture Exhaust System

Function: Removes evaporated moisture from the chamber.

Low-Energy Features: VFD-controlled exhaust fans operate only as needed, preventing the wasteful expulsion of heated air.

8. Safety & Fire Protection System

Function: Ensures safe operation.

Components: Spark detectors, fast-acting fire suppression systems, explosion relief doors, and over-temperature alarms.

Low-Energy Impact: Prevents costly downtime and energy waste from accidents.

Ⅳ. Applications & Customer Value

Ideal For:

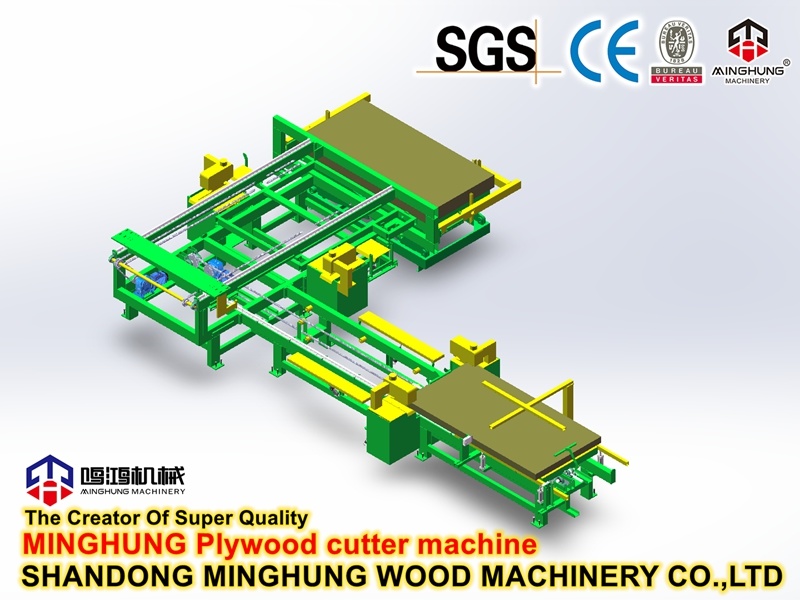

Large-scale continuous production lines for plywood and LVL.

Businesses in regions with high energy costs.

Companies focused on ESG (Environmental, Social, Governance) and reducing their carbon footprint.

Enterprises aiming to reduce production costs and enhance product competitiveness.

Core Value for Customers:

1. Direct Economic Benefit: Lower energy use directly reduces cost per cubic meter of dried veneer. ROI is typically 1-3 years.

2. Enhanced Product Quality: Stable drying conditions reduce defect rates and increase output of high-grade products.

3. Automation & Reliability: Reduces reliance on skilled operators and human error, ensuring stable production.

4. Sustainability: Aligns with global environmental trends, aiding certifications and improving brand image.