What is Plywood?

Plywood is made of three or more thin layers of wood bonded together with an adhesive. Each layer of wood, or ply, is usually oriented with its grain running at right angles to the adjacent layer in order to reduce the shrinkage and improve the strength of the finished piece. Most plywood is pressed into large, flat sheets used in building construction.

In general, Its standard size is 4feet*8feet (1220mm*2440mm), also some people produce the special size according to their markets.

Raw Materials:

The center layers are known as the veneer core. In plywoods with five or more plies, the inter-mediate layers are known as the crossbands. The outer layers of plywood is face veneer, and some will laminating melamine.

Plywood can made from hardwoods, and softwoods, or a combination of the two. Some common hardwoods include birch, beech, acacia wood, mahogany, oak, and teak. The softwood used to make plywood is poplar, pine and others.

The adhesive type used to bond the layers of wood veneer together depends on the specific application for the finished plywood.

Plywood Application:

Plywood has construction plywood, furniture plywood, marine plywood, some mainly used for building construction, some used for inner decoration, some use for packing.

Plywood Size:

The thickness range of Plywood board from 18 mm to 100 mm, some may produe 18mm, this is one common thickness, some may produce 30mm, 60mm, or more. Their application will be different. Although the core, the crossbands, and the face and back of a sheet of plywood may be made of different thickness veneers, the thickness of each must balance around the center. That can make sure the plywood quality is good.

The common size of plywood board usually is 4 ft (1.2 m) wide by 8 ft (2.4 m) long. Also some special size like the width 1700mm.

The Manufacturing Process:

Wood Tree Debarking Peeling Machine

As i know, many plywood factory, they will plant trees by themselves, that can offer themselves logs, save cost, and protect the environment, this is a good idea. Or some will buy logs from local market or import wood, and different markets will use different logs, some use beech, some use birch, some acacia wood, some use albasia.Wood debarker machineWood debarker for saleWood log debarker Wood log debarking machineWood log rotary debarker machineWood chipper debarkerRoller wood debarkerLog debarker

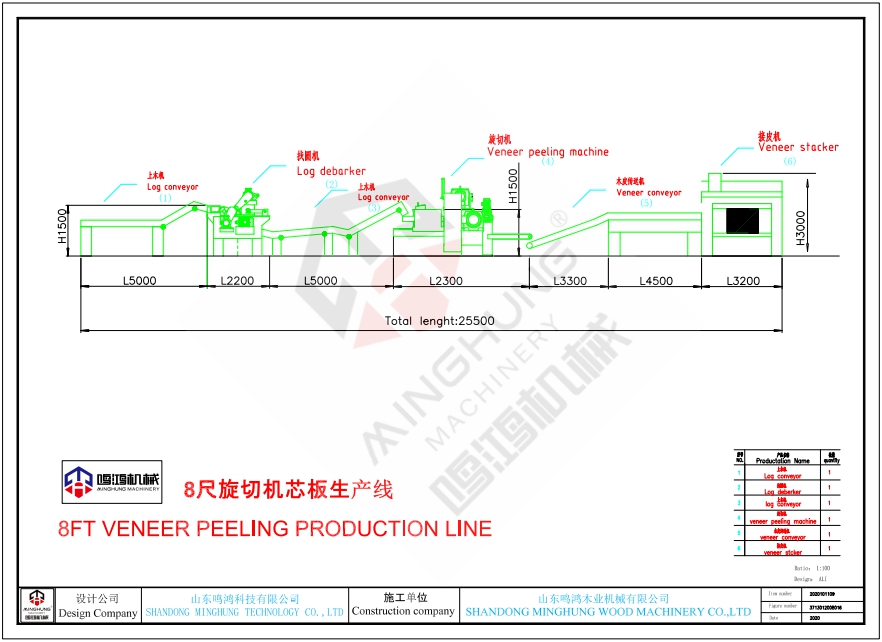

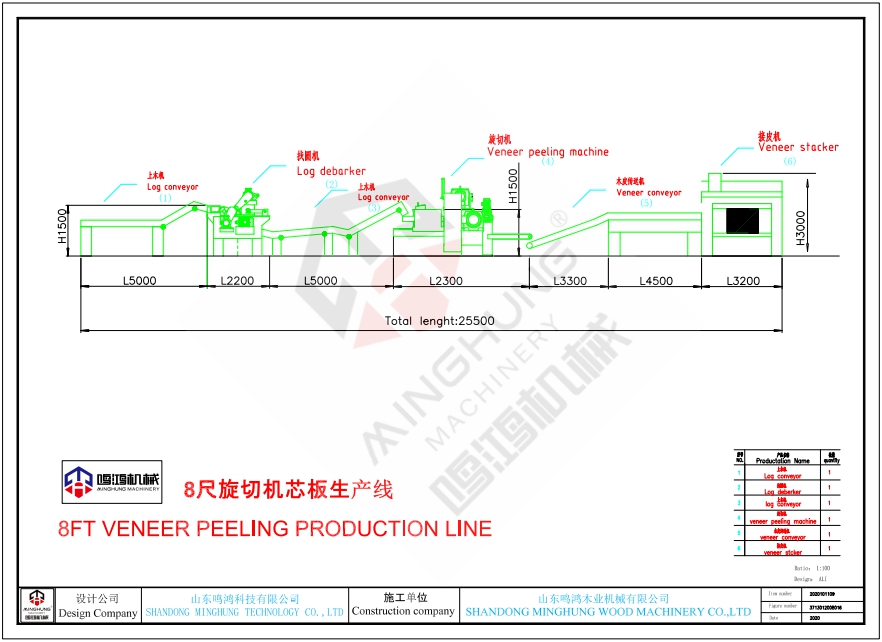

Debarking & Peeling &Stacking:

Through log debarker to remove wood bark, then offer to veneer peeling machine. Before start peeling, the blocks usually will be heated and soaked to soften the wood. The blocks may be steamed or immersed in hot water. This will be easier for veneer peeling machine working.

CNC Spindleless Lathe Machine/Core Veneer Rotary Cutting Machine/Veneer Peeling Machine

Then the heated blocks/logs are transported to the peeler lathe machine, where they are automatically aligned and fed into the lathe one at a time. The max speed of veneer lathe machine can be 80m/min, it is fast and high efficiency, and with the diameter become small, veneer peeling machine’s speed will become faster. And you can adjust veneer thickness and width through cnc screen, very convenient. the max log diameter can be 600mm, the remaining piece of wood, known as the peeler core, is ejected from the lathe and a new peeler block is fed into place.

Rotating veneer peeling machine,Rotary veneer log peeling lathe machine,Wood veneer manufacturing,Wood veneer factory,Wood peeling machine,Wood veneer peeling machine,Wood peeler machine.Wood peeling machine price.Wood veneer machine.

The veneer peeling lathe has different size, if your max log length is 1300mm, then choose the 4feet veneer peeling machine are enough, if your max log length is 2600mm, then choose the 8feet veneer slicing machine is good, if your log length is longer, also no problem, because the factory can customize veneer machine. Wood logs veneer peeling lathe machines.Wood sliced veneer line.Plywood peeling machine.Plywood machinery-veneer peeling machine.Industrial veneer peeling machine

Non-chuck veneer rotary peeling lathe.

The sections of veneer are then sorted and stacked according to grade. This may be done manually, or it may be done automatically using vacuum veneer stacker, using this machine will save two labors and improve work efficiency.

The sorted sections are fed into a dryer to reduce their moisture content and allow them to shrink before they are glued together. Because after produced by veneer peeling machine, the veneer humidity are higher , some may 30%-40%, some may 70%, it is not suitable for making plywood, so need drying wood veneer. Most plywood mills use a mechanical dryer in which the pieces move continuously through a heated chamber. Veneer dryer machine has three types, they are veneer press dryer, veneer roller dryer and face veneer mesh dryer, according to your factory room, production capacity, veneer thickness, then choose the better and suitable one.Plywood Core Veneer Mesh Dryer Machine,Core dry press plywood machine.Veneer dryer.Veneer dryer machine,Veneer dryer manufacturer.Veneer dryer for sale,Veneer dryer machine price,Veneer drying machine,Veneer drying process.Veneer drying line,Mesh Veneer Dryer Machine for Drying Face Veneer,Dehydrated Face Veneer Mesh Dryer Equipment,Dryer Machine Drying Face Veneer with Mesh Conveyor,Veneer Roller Dryer/Plywood Making Machine,Veneer Roller Dryer/Plywood Machine,Veneer Dryer Machine with Roller Drying,Roller Core Veneer Dryer。Roller Veneer Dryer

Glue Spreader Roller Spreading Machine for Plywood Veneer:

Coating glue on the surface of wood veneer by glue spreader, then assembled for a particular run of plywood, gluing the pieces together. The short sections of core veneer are then laid crossways on top of the glued back, and the whole sheet is run through the glue spreader a second time. Finally, the face veneer is laid on top of the glued core, and the sheet is stacked with other sheets waiting to go into the press.Glue Spreader Machine Wood,Glue Spreader Machine,Glue Spreader,Glue Spreader Applicator,Glue Spreader Veneer Machine,Glue Roller Applicator for Glue Machine。4FEET 8FEET Glue Spreader Machine with 410 Diameter Roller,Glue Roller Spreading/Glue Spreader Machine,Plywood Production Line Glue Spreading Machine

Plywood Cold Press for Construction Furniture Plywood and Wood Veneer Hot Press Machine for Plywood Making Machinery : woodworking machine with plywood cold press machine

the glued plywood sheets are loaded first into cold press machine, its max opening is 1800mm, pressure can be 400t 500t 600t, then enter into hot press machine, hot press machine pressure can be 500t, 600t, 800t, 1000t, 1200t or bigger, and it can be 10daylights, 12daylights, 15daylights, 20daylights, 25daylights. the press machine squeezes plywood together under a pressure, while at the same time heating them to a temperature of about 109.9-150 C. The pressure assures good contact between the layers of veneer, and the heat causes the glue to cure properly for maximum strength. After a period of 10 minutes, the press is opened and the sheets are unloaded. Through this step, plywood become strong and good shape.,Plywood Press Machine Cold Press

,Plywood Cold Press Machine, Plywood Pre-Press Machine,Plywood Manufacturing Machine-Cold Press.Plywood Production Line Cold Press,Plywood Production Machine Cold Press,Plywood Veneer Cold Press Machine.Plywood Production Cold Press Machine,Press Machine-Hydraulic Cold Press for Plywood

Plywood Edge Cutting Saw Machine Plywood Trimming Saw DD saw for Plywood

The rough plywood sheets then pass through the plywood edge cutting saw machine, which trim them to their final width and length. The plywood saw machine be guide by infrared, and be controlled by micro-computer, automatic sawing and stacking plywood, very convenient.

The last step, sanding both sides of plywood by sanding machine. Because some place’s thickness are different in one piece plywood, so through sanding machine, their thickness will become accurate and balance, and at the same time, the surface of plywood will become smooth and bright.Plywood Machine Sanding Machine for Calibrating Plywood,Plywood Sanding Machine/Calibrating Machine,Plywood Board Brush Sanding Machine,Plywood Sanding Machine in Wood Based Panels Machinery,Plywood Brush Sanding Machine,Precise Plywood Calibrating Machine/Sanding Machine,CNC Sanding Machine for Plywood Making

The finished sheets are stamped with a grade-trademark that gives the buyer information about the exposure rating, grade, mill number, and other factors. Sheets of the same grade-trademark are strapped together in stacks and moved to the warehouse to await shipment.

Until now, the whole plywood manufacturing process has finished. Believe you have know clearly that how to produce plywood, and what kinds of plywood machine you need.

Our factory is China professional manufacturer of plywood machine and veneer machine with many years, with advanced technology, professonal engineers and workers, good sales team, we have ability and sincere offer you good and suitable plywood machine.

if you are interested, welcome contact us.

Whatsapp: MARK:+86 18769900191 ALI: +8615589105786 LUCINDA: +8615805493072

Email: shandongminghung@gmail.com

garysinghco@gmail.com linyiminghungmachinery@gmail.com