Ⅳ. Full Automatic Calibration System (Core Production Safeguard)

Why is Calibration Needed?

During high-speed operation (e.g., >8 m/min), the two steel belts (each potentially over 100m long and weighing tens of tons) work under high temperature and pressure for extended periods.

Belts are inevitably prone to lateral deviation (running off-track) due to thermal expansion, uneven friction, roll installation errors/wear, mat entry impact, etc.

Minor deviation causes belt edges to rub against the frame, leading to severe wear or even tearing.

Major deviation can cause belt derailment or jamming, resulting in catastrophic equipment damage and prolonged downtime.

Deviation also affects uniform heat and pressure distribution on the mat, causing uneven board thickness, pre-cured layer variations, or even localized uncured areas.

What is the Full Automatic Calibration System?

This is an integrated closed-loop control system comprising sensors, controllers, and actuators. Its core function is to continuously monitor the real-time position of both steel belts relative to the frame centerline. Upon detecting any minor deviation, it automatically, rapidly, and precisely adjusts the angle or position of specific rolls to steer the belt back onto its designated center path, all without manual intervention.

System Components & Working Principle:

1. Sensing & Detection:

Key Components: High-precision, high-temperature resistant non-contact displacement sensors (e.g., laser distance sensors, ultrasonic sensors, edge position detectors) installed at critical locations: press inlet, outlet, and along the press length (especially before/after main pressing zones).

Function: Continuously and real-time measure the distance of the belt edge or specific markers relative to a reference position.

2. Signal Processing & Control:

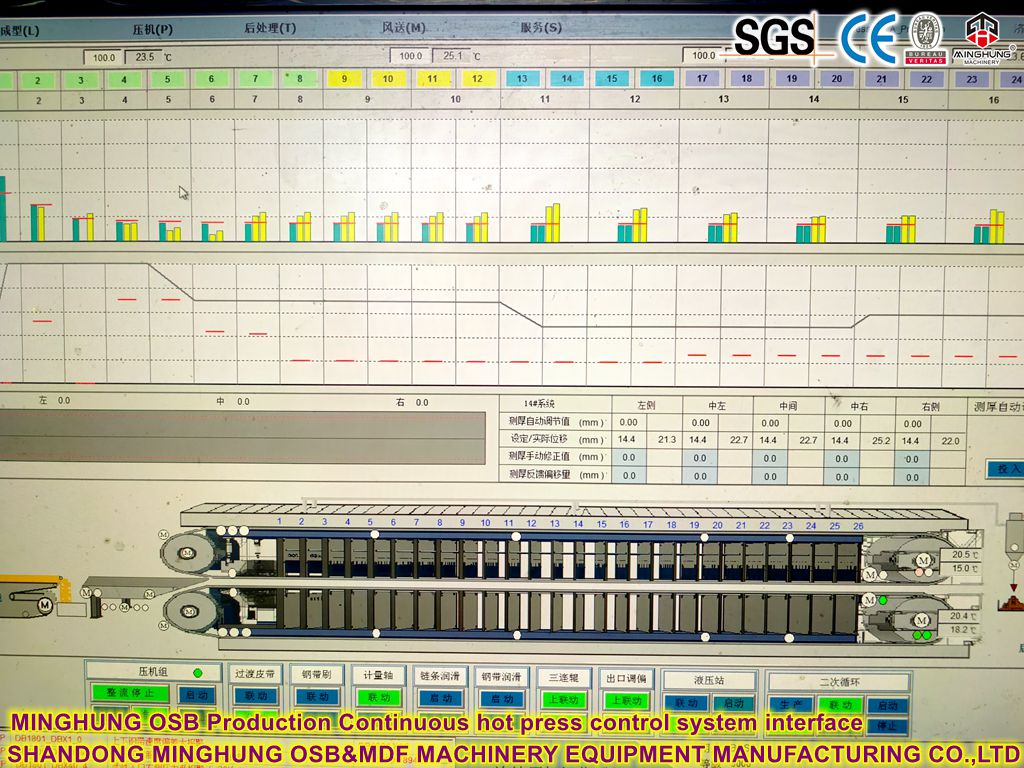

Key Component: PLC (Programmable Logic Controller) or dedicated motion controller.

Function: Receives sensor signals, calculates the deviation value (magnitude and direction) of the belt's current position from the set centerline. Using preset control algorithms (e.g., PID control), calculates the required correction force (adjustment amount) and direction. Sends precise control commands to actuators.

3. Actuation:

Key Components:

Hydraulic Cylinders / Servo Cylinders: Most common actuators, offering fast response and high force. Typically mounted under the bearing blocks of steering rolls or tension rolls.

Precision Servo Motors + Ball Screw / Rack & Pinion: Used where extreme precision is needed.

Function: Receive controller commands, rapidly and precisely push/pull one end (or both ends cooperatively) of a roll, inducing a minute tilt angle ("deflection") in the roll's axis. This slight angle change alters the friction force direction at the roll/belt contact point, generating a lateral force to "push" or "pull" the deviating belt back to center.

4. Closed-Loop Feedback:

Sensors continuously monitor the belt position after adjustment, feeding new data back to the controller.

The controller issues further adjustments based on the new deviation until the belt stabilizes within the allowable tolerance. This forms a dynamic, real-time closed-loop control process.

Technical Highlights & Advantages:

Real-Time & Fast Response: Millisecond-level response corrects deviations as soon as they begin, preventing escalation.

High-Precision Control: Maintains belt run-off within ±1mm or less.

Multi-Point Monitoring & Coordinated Control: Multiple detection and actuation points along the press length enable comprehensive and coordinated control.

Automation & Intelligence:

Unattended Operation: Eliminates need for constant operator monitoring and manual correction.

Adaptive Adjustment: Automatically optimizes control parameters based on changes in speed, temperature, or mat characteristics.

Fault Diagnosis & Early Warning: Records operational data, analyzes deviation trends, predicts potential issues (e.g., roll wear, sensor failure), and triggers alerts proactively.

Core Value:

Ensures Equipment Safety: Minimizes risk of catastrophic accidents and costly downtime caused by belt deviation.

Guarantees Product Quality Stability: Eliminates quality defects like uneven thickness, density variations, and surface flaws caused by deviation, improving yield and premium product rate.

Extends Equipment Lifespan: Reduces abnormal wear on critical components (belts, rolls, bearings).

Enables High-Speed Production: The fundamental prerequisite for stable, safe, long-term operation at speeds like 25,000 m²/day. Reliable automatic calibration is essential for high-speed operation.

Reduces Maintenance Costs & Labor Dependency: Minimizes emergency repairs and frequent manual adjustments.

The high-speed MDF continuous flat-press (25,000 m²/day) equipped with a full automatic calibration system is the crown jewel of modern man-made board manufacturing. It perfectly combines extremely high production efficiency with exceptional production stability, safety, and product quality. MDF, as a high-performance, versatile panel, relies heavily on such advanced equipment for its large-scale, high-quality production. The Full Automatic Calibration System is the core technological safeguard ensuring the safe, stable, and high-quality operation of the press at its maximum speed, directly impacting the production line's economic efficiency and competitiveness. This type of equipment represents the pinnacle of man-made board machinery technology and is the standard configuration for large-scale, modern MDF production lines.