Ⅱ. Key Components & Features of the 3mm Thin-Board High-Speed Continuous Flat Press Line

1.Fiber Preparation System (Specially Optimized):

Refining / Re-refining: Requires extremely high fiber quality. Fibers need to be longer, finer, and more uniform for better interlocking and mat strength. May require specialized refiners or re-refiners.

Drying: Moisture content of dried fibers must be precisely and uniformly controlled, critical for subsequent gluing and press stability. Uses efficient, precisely controlled pneumatic drying systems.

Resin Blending: Precise control of adhesive application (typically UF or MUF resin). May require special additives (e.g., wax emulsions, hardeners) to optimize mat behavior and curing speed. Uniform resin distribution is paramount.

refiner for MDF

drying system

drying system

glue mixer system

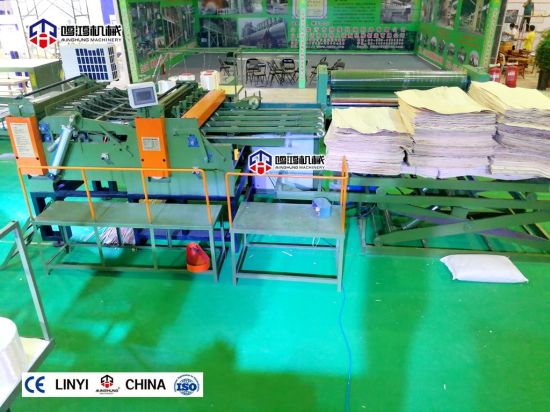

2.Mat Forming System (One of the Most Critical Sections):

High-Precision Forming Heads: Employs state-of-the-art mechanical or air forming technology (or a combination) to ensure extremely uniform fiber distribution, free of clumps or voids. Surface fibers need to be finer.

Mat Pre-Pressing: Powerful continuous pre-press (usually dual-belt or roller type) applies high pressure to compact the fluffy mat, significantly increasing the green mat strength and integrity before entering the main press. This is a core measure to prevent ultra-thin mat breakage during high-speed press entry.

Mat Edge Trimming & Squaring: Precise edge trimming ensures neat, compact edges, reducing edge damage at press entry.

Mat Online Scanning: May include scanners for real-time monitoring of mat thickness and density profile, providing feedback for forming control.

mat forming machine

continuous pre-press machine

continuous pre-press machine

3.Continuous Flat Press (Core Equipment, Specially Designed):

3.1 Infeed "Soft-Entry" Technology: Critical for 3mm production! At the main press infeed, a special pressure profile is applied (typically starting very low and increasing gradually). This allows the extremely fragile thin mat to be gently and smoothly "nipped" by the steel belts without impact shock, gradually starting compression. Prevents mat shattering or buckling at the infeed due to abrupt pressure changes. Achieved via precisely controlled segmented hydraulic cylinders or specially designed infeed rolls.

3.2 Heating & Pressing Section:

Ultra-High Heat Transfer Efficiency: Optimized platen design (e.g., internal channeling), high-temperature thermal oil (typically >220°C or higher), and minimal clearance between belts and platens ensure heat is transferred extremely rapidly to the core of the thin mat for fast curing.

High-Precision Thickness Control: Pressure and gap height (opening) for each press zone (dozens or even hundreds) are independently, precisely, and rapidly controlled. High-resolution displacement sensors monitor belt position (i.e., board thickness) in real-time. Closed-loop control systems dynamically adjust cylinder pressure to ensure minimal and stable thickness variation across the entire board.

High Pressure: Requires higher pressures (possibly exceeding those for standard boards) to overcome fiber springback and achieve target density, especially in the surface layers.

Special Steel Belts: May use thinner, smoother, higher thermal conductivity belts to reduce thermal resistance and improve surface finish.

3.3 Outfeed Section: Requires precise control of pressure release profile to prevent board springback or distortion.

High-Speed Stability: The entire press frame, drive system, belt guidance, and tensioning systems are reinforced for high-speed operation, ensuring minimal vibration and smooth running.

steel belt for continous flat press

hydraulic pressure station

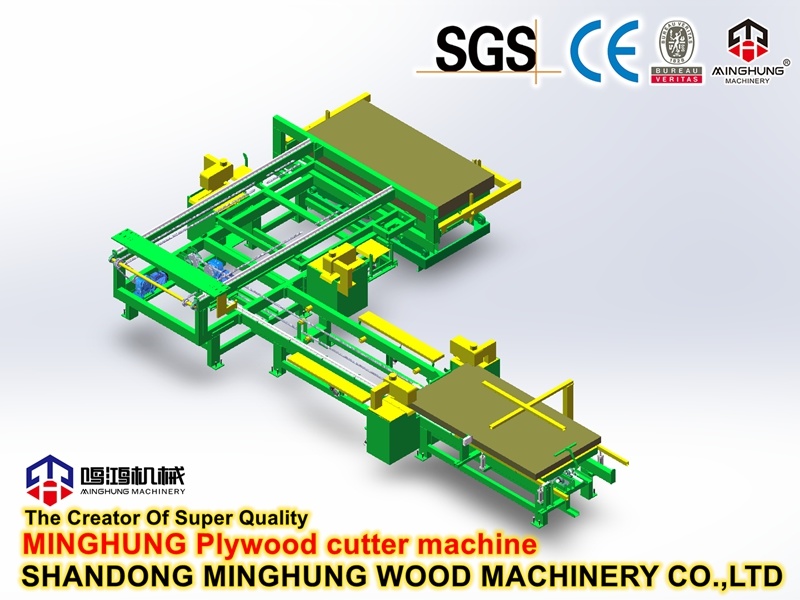

4.Board Handling & Cooling System:

High-Speed Cross-Cut Saw: Precisely cuts the continuous board strip to length at high line speed.

Acceleration Roller Table / Star Wheels: Rapidly separates sawn boards to prevent stacking collisions.

Cooling Racks / Cooling Roller Table: Efficient cooling is crucial. Internal heat in the thin board must be dissipated rapidly to stabilize dimensions and prevent deformation (warping, wavy edges) during subsequent stacking. May employ strong air cooling, water-cooled rollers, or a combination.

edge trimming and cutting machine

cool racks

5.Sanding Line (Extremely Important):

High-Precision Calibrating Sanding: Due to the thin pre-cured layer and minimal sanding allowance (possibly only 0.15-0.3mm), sanding depth control must be exceptionally precise (e.g., ±0.02mm). Typically uses multi-head sanders (4-8 heads).

Fine Sanding: Initial heads handle high-precision calibration and pre-cured layer removal. Subsequent heads achieve the desired surface finish (low Ra value).

Online Thickness Monitoring & Feedback: High-precision scanners before and after sanding monitor thickness and profile in real-time, automatically adjusting sanding depth.

Dust Extraction: Powerful dust extraction systems handle the high volumes of dust generated by high-speed sanding.

double-sided four-frame sander

double-sided four-frame sander

sander for mdf machine

6.Stacking & Packaging:

Automatic stackers for neat piling of finished boards.

Strapping machines for bundle protection.

Ⅲ. Key Advantages of a 3mm-Specialized Line

1.Ultra-High Production Efficiency: Continuous operation and high speed deliver massive output advantages, far exceeding the capacity of batch or multi-daylight presses.

2.Exceptional Product Quality:

Minimal and stable thickness tolerances.

Uniform density profile, stable structure.

Extremely smooth, flat surfaces with minimal pre-cured layer.

Excellent and consistent physical/mechanical properties.

3.Superior Dimensional Stability: Precise process control and efficient cooling significantly reduce warping and deformation common in thin boards.

4.High Raw Material Utilization: Precise control reduces waste (e.g., breakage, thickness rejects).

5.High Automation & Intelligence: Highly integrated control systems (e.g., DCS, MES) enable precise monitoring, automatic adjustment, and optimization of process parameters. Reduces reliance on operator experience and enhances production stability.

drying system

drying system

continuous pre-press machine

continuous pre-press machine

double-sided four-frame sander

double-sided four-frame sander